State of Manufacturing 2014: Making Progress

Manufacturing employment can grow by more than 300,000 jobs every year and the economy can grow by an additional $1.5 trillion. It all comes down to products, people and policy.

Posted: March 14, 2014

Manufacturing output has increased 18 percent since the end of the recession in 2009. Last year, manufacturers contributed a record $2 trillion to our economy. Our manufacturing sector alone is larger than the entire economies of all but seven countries, and manufacturing exports have reached an all-time high.

So today I’m pleased to report to you that manufacturing in America is making a comeback. That’s a tribute to the hardworking men and women who produce the goods and generate the ideas that power the U.S. economy as well as the global economy.

Manufacturing is the lifeblood of the U.S. economy. That’s why President Obama regularly talks about the importance of manufacturing, and our industry has supporters across the political spectrum. Two top Texas Republicans — Gov. Rick Perry and Sen. John Cornyn — are strong advocates for manufacturing.

Blue-chip consulting firms like McKinsey & Company (New York, NY) and the Boston Consulting Group (Boston, MA) are also touting the transformation that’s underway in manufacturing. Many media outlets are on board as well. A cover story last year in Barron’s, the weekly financial newspaper, described the country’s manufacturing “revival.” They see what those of us in manufacturing have always known: this industry has driven the innovation and created the opportunity that’s made the American economy the envy of the world.

My grandfather left the family farm to work at the local Mead paper plant in Chillicothe, OH, during the Great Depression. He did so because he knew that manufacturing would allow him to provide a better life for his family. His was a lifetime career of 40 years — until he retired.

Today, manufacturing is a lot different than it was in my grandfather’s day, but it still allows more than 12 million men and women to provide a good life for their families. At the NAM, we represent more than 12,000 manufacturers who make that possible — manufacturers of all sizes and in all sectors who want to grow their business and create quality, good-paying jobs.

The question we confront is, “How do we ensure that manufacturing in the United States is robust, dynamic and ready to meet the needs of our economy and our workers?”

Consider this finding from the Manufacturers Alliance (Arlington, VA): Manufacturing employment can grow by more than 300,000 jobs every year and the economy can grow by an additional $1.5 trillion if manufacturing’s share of the U.S. economy rose from 12 percent to 15 percent — where it was at the beginning of the last decade. So what do we need to do to achieve this goal? It all comes down to a focus on three specific areas: products, people and policy.

PRODUCTS

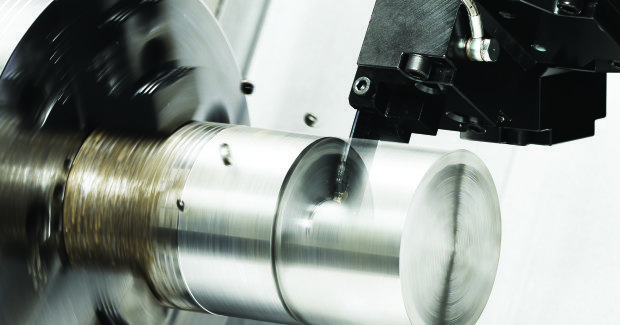

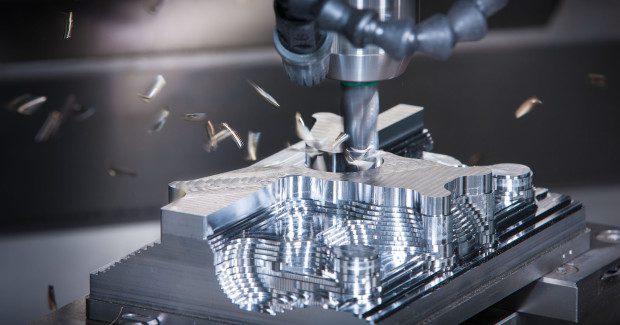

Let me start with products. Manufacturers in America are making more products today and making them better than ever before. While manufacturing declined as a share of the American economy for decades, it has grown in the past few years, even as the broader economy needed to be juiced up by the monetary equivalent of steroids.

Innovation is a big reason why manufacturing products like cars and trucks are making a strong comeback. The ability to adapt, innovate and improve is at the foundation of the U.S. economy, and it shows up in abundance in manufacturing in America.

One incredibly innovative company headquartered in Lexington, KY, has an unforgettable name: Big Ass Solutions. This manufacturer has taken products that might seem ordinary —fans — and innovated around them. The company’s insight was to couple energy-efficient motors with patented airfoil designs to move large volumes of air quietly and efficiently.

The company generated $122 million in revenue last year. I’ve likely helped boost that number this year since I’m renovating my home and have bought four of its fans. Innovation is complemented by perhaps the most important force boosting the manufacturing sector: the boom in domestic energy production, which is a byproduct of American-led innovation.

Affordable natural gas has made production more cost-effective for manufacturers across the board. The result is more jobs for workers and more economic growth for Texas and for the United States. One manufacturer with operations here in Houston — LyondellBasell — announced last month that because of the price advantage from shale gas, it reopened a methanol plant that had been closed for nine years.

That’s just one example of how manufacturing is benefiting from affordable natural gas. $90 billion of new private-sector manufacturing investments in the chemical sector are planned, according to the American Chemistry Council. $90 billion! The shale revolution is big. You know that already. But more Americans need to understand how the shale revolution is going to transform everything we do in this country. It will drive a long-term comeback for manufacturing — unless Washington gets in the way.

So that’s the good news. When it comes to manufacturers and manufacturing workers doing what they do best — making and selling products to the world — we’re making solid progress.

PEOPLE

However, there are challenges ahead, and the first one has to do with people. The people involved in manufacturing are second to none. From the CEO’s office to the shop floor, manufacturing attracts some of the most dedicated, hardworking, innovative and talented women and men in America.

Manufacturing attracts our nation’s finest. Travis Atwood left the Army after serving two tours in Iraq. He returned home to Texas and got into manufacturing. He wanted to make things, and he found a perfect outlet in the oil and gas industry. As Travis puts it, “Manufacturing provides the opportunity to do something that matters, to work with exciting technology to build a product that either helps people’s lives or helps other businesses solve some of the toughest problems in the world right now.”

Today, he’s part of the Junior Officer Leadership Program at GE Oil & Gas, and he’s currently in the middle of an eight-month rotation in the drilling division. He’s able to translate the skills he received in the military — leadership, teamwork and more — to a job in manufacturing.

I’ve heard similar stories from other veterans as well. Whether it’s leadership abilities or technical know how, manufacturers are catching on that the military offers incredible talent. And more and more, young people are seeing manufacturing as an exciting and fulfilling career. There’s a future in manufacturing, and they’re seizing it.