CAD/CAM Sheet Metal Fabrication Software: The Latest Trends and Advances

These new systems showcase how CAD/CAM software for sheet metal and structural steel fabrication is coming of age to meet the increasing needs for speed in job shops, contract manufacturers and metal service centers.

Posted: April 23, 2014

Take-off from blueprints. Job cost estimation. Component part and assembly design. Routing and capacity planning. Materials procurement. Process planning and scheduling. Machine tool programming.

What do all of these things have in common?

An increasing need for greater speed.

In every manufacturing facet of winning, planning and delivering a profitable job, sheet metal and structural steel fabricators must pick up speed to remain competitive. Quicker job turn around means faster payment and increased cash flow. To this end, the emphasis on lean manufacturing that has revamped and automated much of how a job is built on the shop floor is now getting its legs in automating front office operations that create the job in the first place – from quoting a price to the customer to part nesting flat sheet for laser cutting to the bending sequence followed by a press brake.

Innovations in CAD/CAM sheet metal and structural steel fabrication software have taken front and center stage in completing all of these tasks and more – not just faster, but more efficiently – as shown in the following examination of various CAD/CAM metal fabrication software tools that are now available.

MANAGE EVERY ASPECT OF FACTORY BUSINESS IN REAL TIME

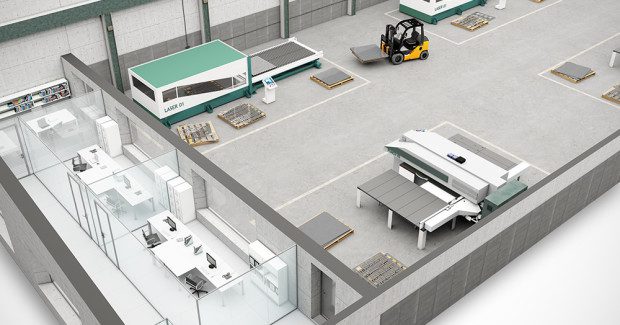

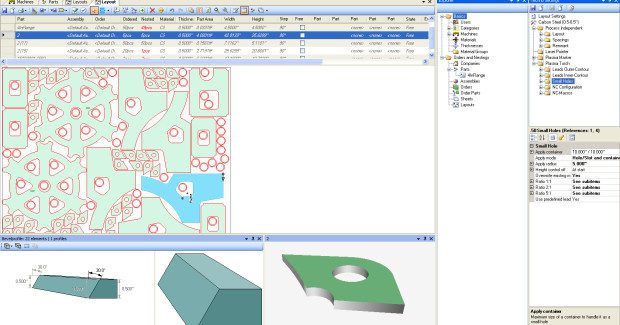

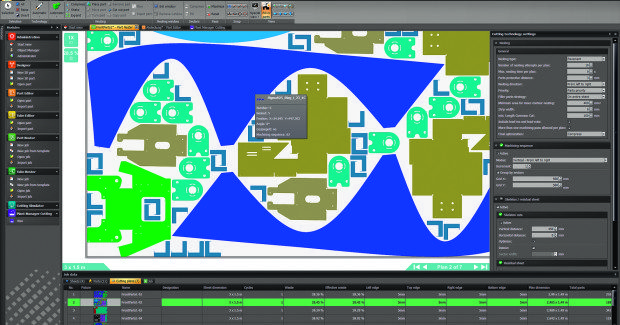

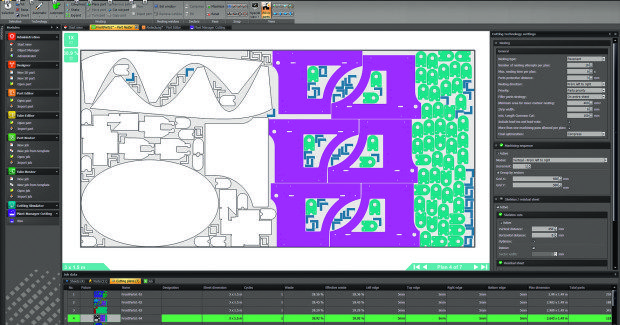

Running a successful business requires collaboration and cooperation between a whole range of job functions, enabling them to work together to maximize customer satisfaction while optimizing profit margins. Shops in the sheet metal and structural steel industries can manage every aspect of their businesses in real time using the Lantek Factory concept from Lantek Systems, Inc. (Mason, OH), which brings together all of their products into one dedicated software solution through a suite of software that covers manufacturing, CAD/CAM and management.

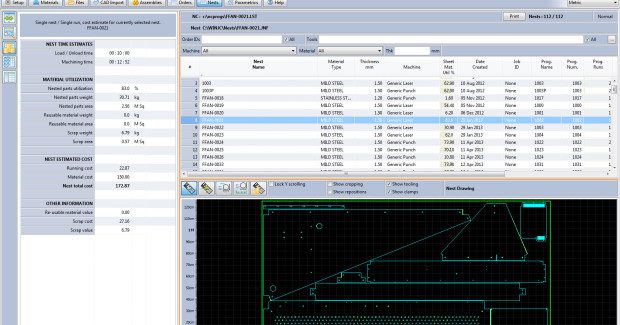

A demonstration and overview of Lantek Factory.

The technology starts with the rapid generation of the quotation from accurate pricing sourced from historical data and the analysis of the cutting and fabrication operations, while customer relationship management records sales performance, customer interaction and orders placed. Information sharing in real-time is at the heart of the concept, working from a common database across the whole company. Starting with the Sales Team and customer relationship management, quotations can be prepared and delivered in minutes, producing accurate pricing from live information about material costs, production times and expected profit margins.

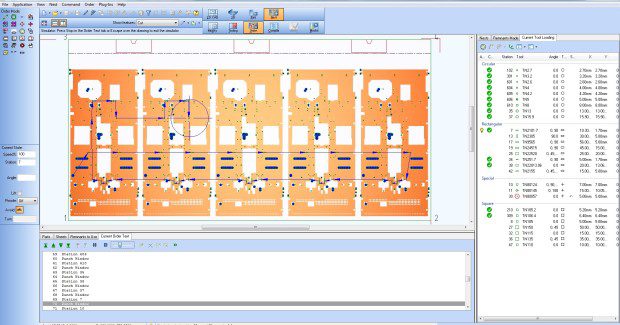

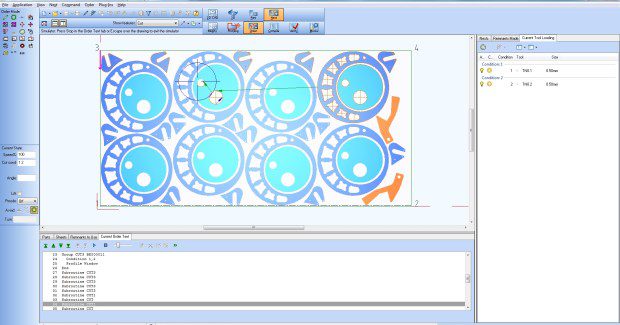

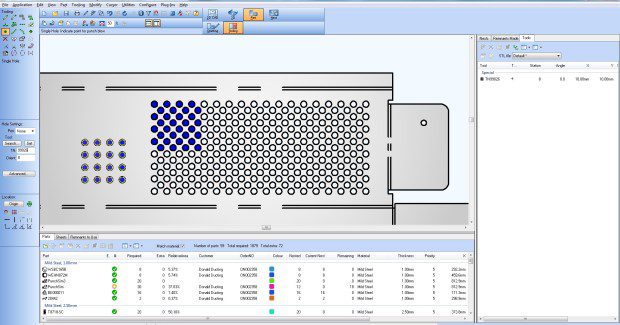

Based on current workload, the Sales Team is able to offer realistic delivery times, building customer confidence and helping to build a long term business relationship. Once accepted, the sales order is processed and passed to production planning where the production order is placed and the job is fitted into the production schedule. Next the production engineers create the program, allocating the machine and the material and nest the parts to maximize material utilization. Shared information goes to the warehouse where material is delivered to the allocated machine ready for manufacture and stock levels are updated triggering reordering of material where necessary.

New orders use the information from the quotation, avoiding duplication of data entry and are scheduled into the factory workload ensuring on time delivery. CNC cutting programs are produced for the mix of parts on order, maximizing material utilization and utilizing remnants where appropriate. The warehouse module takes the bill of materials from the quotation and ensures material and any other parts are ordered, stock controlled and made available for production as they are required, while live reporting on the machine and in the warehouse, feeds back cost information on each job, collates any certification and monitors progress through the workshop.

On the machine, the operator logs start and finish times to record the status of the job and the manufacturing times as the parts are being produced. This real-time information goes to the Administration team where delivery notes and invoices are raised, information about the cost of the job consolidated and instructions for shipment of the parts issued to the warehouse.

Lantek Workshop Capture is fully integrated into the Lantek Integra ERP system for easy access to accurate, real-time shop floor data for informed decision making and production monitoring. All aspects of shop floor activity can be recorded including time and attendance, production downtime, job status, manufacturing times and operations to be completed. As the information is recorded when it happens, the Lantek Integra server will have the most up to date information in its database.

For managers, the ability to check the current status of a job, analyze time management, examine machine or operation performance and determine costs for each part is invaluable. With this information they can keep customers informed, rearrange manufacturing priorities where necessary, check budgets and make decisions on equipment, all based on reliable information. They have an overview of the complete process so that they can monitor production and the status of individual jobs and keep themselves informed about overall business metrics such as profit margins, sales and delivery performance.

For operators, data entry is easy using touch screen technology, keyboard entry or barcode depending on the device most suited to the application. The newly designed clear graphical interface makes working with Lantek Workshop Capture quick and intuitive, ensuring that it can be rapidly learnt and implemented. With the system, production personnel can perform tasks such as clocking in and out, recording start and finish times for each operation, identifying anomalies and logging machine downtime.

The system is not limited to metal fabrication operations, so tasks such as CAM programming, assembly, welding or painting can be recorded just as easily with Lantek Workshop Capture. Entering data as it happens results in much more accurate information being recorded as it largely eliminates transcription errors, duplication of tasks and human error producing further benefits such as reduced administrative effort and less time and material lost through production mistakes.

This suite would be ideal for a shop such as LaserMaster (Cornwall, UK) a fabricator that already uses Lantek Expert CAD/CAM software and the Lantek Integra ERP system. Formed 11 years ago, LaserMaster initially manufactured its own range of carpet cleaning machines, but now the bulk of its business is subcontract sheet metal and fabricated products for a wide variety of industries including aerospace, motor sport and automation. Previously it used CAD/CAM software from another leading supplier, but poor levels of support led it to replace the system with Lantek Expert.

Early in 2013 the shop invested in a new Bystronic BySprint 4 kW fiber optic laser with ByTrans automated sheet load/unload and, at the same time, upgraded its Lantek Expert software and installed Lantek Integra ERP, replacing its existing Bystronic 3015 3.5 kW laser. Tim Hicks, a CAD/CAM engineer at LaserMaster, says, “We upgraded the software to complement the more efficient cutting we can get from the new Bystronic, which has been a £0.5 million ($828,900) investment for us. We have had experience with all the other leading CAD/CAM systems, and they have not been able to touch this system for performance and nesting efficiency.”

To fill the available capacity that the new machine has created, this shop needs to produce around 50 quotes every day. Hicks states, “It is vital for us to get the quotes done very quickly. All the parts we produce are different with the occasional repeat order. Lantek Integra communicates with Lantek Expert to calculate material usage and cutting times. It also includes information about material costs to give us accurate selling prices. In addition, the system monitors the success rates for our quotations so we can see how we are performing against our sales targets.”

With Lantek Manager, the shop can keep track of the status of each job and its location on the floor, ready for secondary operations such as bending or painting. The solution is also able to generate sales orders, invoices and delivery notes, all related to the original quotation. Hicks adds, “We can log into the system to check that no parts are missed and that all the operations have been completed.”

Hicks explains, “The Bystronic and Lantek software combination is 50 percent more efficient than our previous setup and we have the potential to produce four times more work than before. We are working towards making this a reality. Already we are seeing more quotations turn into orders. The software suite is essential part of this success.”

Lantek Systems, Inc., Mason Technical Center, 5155 Financial Way, Mason, OH 45040, 903-258-9422, Fax: 513-322-4567, www.lankteksms.com.