CNC Predictive and Preventative Maintenance Tools for Motors and Fans

The innovative Series 30i/31i/32i-MODEL B CNCs from FANUC FA America offers predictive and preventative maintenance tools for motors and fans that allow shop maintenance personnel to pre-plan servicing of a machine during scheduled downtime rather than when a machine has failed.

Posted: April 2, 2014

The innovative Series 30i/31i/32i-MODEL B CNCs from FANUC FA America (Hoffman Estates, IL) offers predictive and preventative maintenance tools for motors and fans. This allows a shop maintenance staff to pre-plan servicing of a machine during scheduled downtime rather than when a machine has failed.

FANUC amplifiers address predictive motor failures by checking the resistance of the windings. The greatest cause of servo motor failure is coolant infiltration into the motor. Coolant works its way into the machining process and deteriorates the windings until a short circuit occurs.

The latest FANUC amplifiers are now able to record the winding resistance and predict when the motor will fail. This allows maintenance personnel to order a motor in advance and change the motor when it is convenient for them, not at an inconvenient time when the machine is down.

An overview of how Series 30i/31i/32i-MODEL B CNCs allow a shop maintenance staff to pre-plan servicing a machine during scheduled downtime rather than when a machine has failed.

The ability to monitor the speed of each fan in the amplifier and the CNC can prevent a failure. On the CNC and servo amplifiers that are contained within the magnetics cabinet, heat is the largest cause of failure. FANUC uses cooling fans to cool electronic components. A failure of the cooling fan can cause a failure of the CNC. By monitoring the speed of each fan that is in the CNC and amplifier, FANUC is able to judge when the fan will fail enabling maintenance personnel to do maintenance at their convenience.

This latest generation Panel i PC uses SSDs which are faster and more reliable than standard hard drives. Utilizing Windows Embedded instead of a desktop operating system increases the reliability of the operating system by allowing it to be locked down-making it much more secure against viruses.

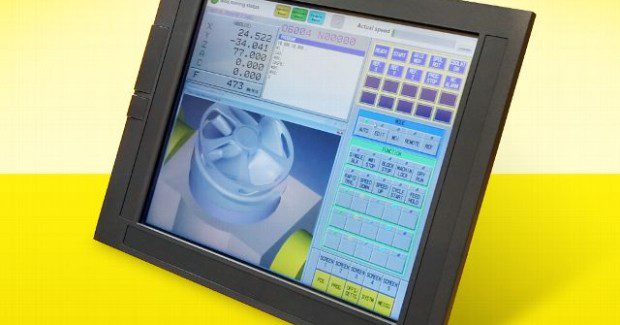

The Panel i large touch panel makes it easier for the operator to control the display and also has a larger area to do 3D modeling of part programs in addition to showing CNC operation. Additional features include enhanced CPUs and graphic capabilities for the larger display that address the needs of higher performance applications today.

An overview of the FANUC Panel i Industrial PC Touchscreen.

Windows Embedded is a product of Microsoft.

FANUC Corporation, headquartered at the foot of Mt. Fuji, Japan, is the most innovative manufacturer of Factory Automation (FA), Robots and Robomachines in the world. Since its inception in 1956, the company has contributed to the automation of machine tools as a pioneer in the development of computer numerical control equipment. Its technology has contributed to a worldwide manufacturing revolution, which evolved from the automation of a single machine to the automation of entire production lines.

FANUC FA America is the exclusive provider of industry leading FANUC CNC systems and solutions in the Americas, providing a one-stop shop for comprehensive CNC solutions including industry-leading control systems, a complete range of drives and motors and CO2 laser solutions.

The company also offers engineering support, genuine parts, repair and factory automation solutions and training programs to machine tool builders, dealers and users. Their CNC systems are known throughout the world for their high reliability, high precision, high speed and simple operation.

FANUC FA America headquarters is located in Hoffman Estates and supports 43 offices and service centers throughout U.S., Canada, Mexico, Brazil and Argentina.

FANUC FA America, 1800 Lakewood Boulevard, Hoffman Estates, IL 60192, 888-326-8287, fanuc.marketing@fanucfa.com, www.fanucfa.com.