Engineered Workholding Solutions

A review of some of the latest advanced workholding solutions that meet tighter specs, tighter tolerances for location accuracy, and ease of loading as they help to speed up processes and improve throughput.

Posted: April 28, 2014

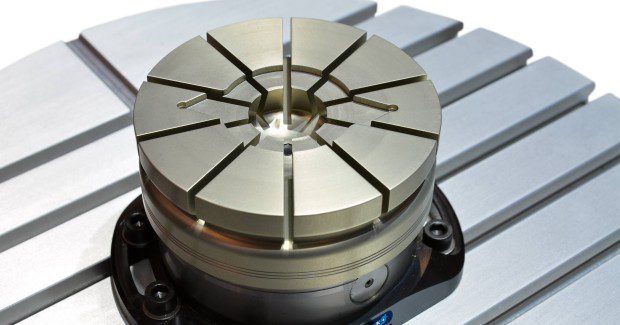

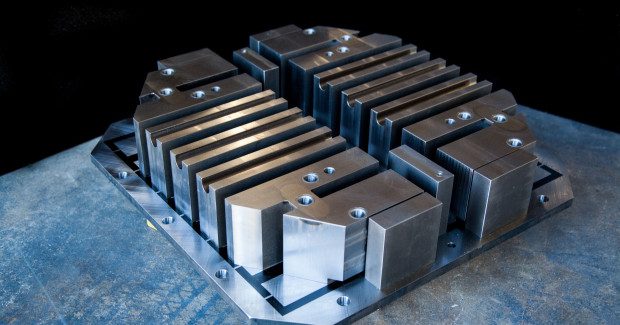

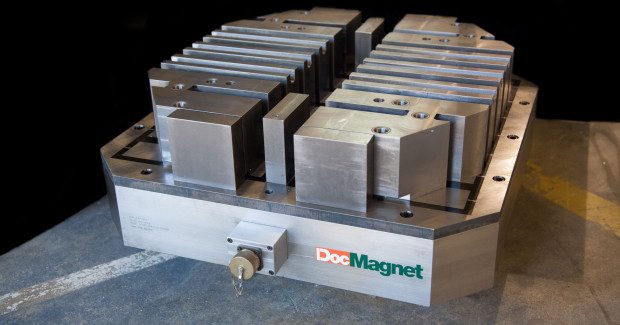

One turn-key system often overlooked is magnetic chucks. The magnetic milling chuck was first implemented on machinery to reduce set up times between unique parts, it has uniform clamping of the entire part in contact with the chuck, reducing vibration therefore extending tool life and the end result is a better workpiece finish. The magnet is capable of repeatable location through adding a side, end stop or dowel pins and the power of the magnet has made it a choice consideration over conventional or hydraulic clamping.

Designing this magnetic turn-key solution is not an easy task. The first step is to look at the application itself, the entire production process must be understood in order for the system to be built to meet the specific needs of the production. The workpiece is the center of attention, the material type, material hardness, overall dimensions, condition of the raw material, and the dimensions/tolerances of the final product must all be factored into the solution. Choosing the appropriate magnetic pole design for the application is the next step in the process for the pole design dictates how the magnetic flux will balance, the depth of the magnetic field, and the overall magneto-motive force of the magnetic circuit.

DocMagnet, Inc., 6220-100 Angus Drive, Raleigh, NC 27617, 919-788-7999, Fax: 919-788-7861, www.docmagnet.com.

OD HOLDING CLAMPS LOCK & PRECISELY LOCATE WORKPIECES WITH IRREGULAR SHAPES

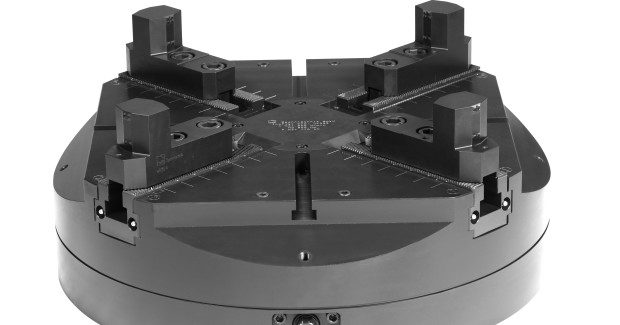

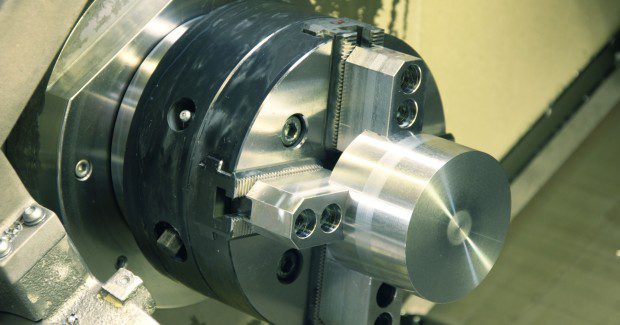

Fixtureworks® Workholding Technologies (Fraser, MI) offers Imao OD holding clamps as part of its workholding and fixturing technologies. The OD clamps, available in up to 90 mm diameter sizes in both round and square styles, allow for holding on irregular shapes and those workpieces with a circumference. The four-part aluminum jaws can also be machined to custom fit the part, while the body is made of SAE-1045 alloy steel to provide for a strong and solid base. The clamps allow for part repeatability of ± 0.03 mm and jaw locating repeatability of ± 0.02 mm, while the clamping stroke of each jaw is 0.15 mm, ideal for clamping die cast parts, extruded, solid-drawn and prefinished parts to name a few.

The clamps come with a diamond pin for body locating. The shaft and locking screw are made from alloy steel, hardened with black oxide finish. When the locking screw is tightened the central bottom part of the jaw is pulled down. At the same time the four jaw sections, applying equal pressure, tilt toward the center to clamp the circumference of the part. The jaws, also available separately, can be machined to hold almost any shape and many different materials can be clamped. An adapter is also available so that the clamps can be used on a lathe. Ease of use is straightforward. Insert the diamond pin (included) into the body for locating. Secure the body to the fixture with four socket head cap screws. Engage the keyway on the bottom of the jaw. Secure the jaw. Set the locking ring in the jaw. After machining, loosen the locking pin.

Besides the Imao OD Clamps, Fixtureworks offers Fairlane® Products full line of grippers, rest pads, Swivots® swivel/pivoting positioning components, Quick Release ball-lock pins, rollers and bumpers; Kipp® rest and riser pads, levers, handles, knobs, and hand wheels; Imao® manual clamps, supports and stops, risers, T-nuts, sliding mounts, springs, supports, grid plates and blocks; OK-Vise® single and double wedge clamp designs; Mitee-Bite® low-profile edge clamps.

Fixtureworks Workholding Technologies, 33792 Doreka, Fraser, MI 48026, 586-294-1188, Fax: 586-294-4843, info@fixtureworks.net, www.fixtureworks.net.

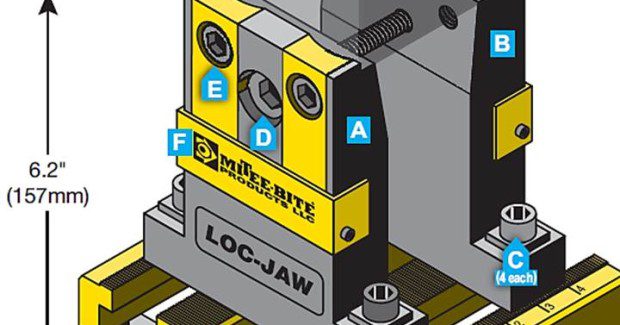

MODULAR MULTI-PART CLAMPING SYSTEM MAXIMIZES MACHINING CENTER PRODUCTIVITY

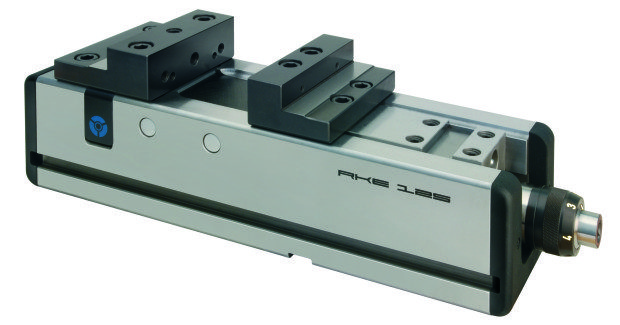

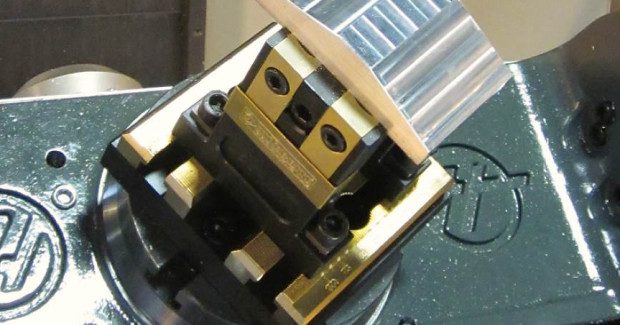

The modular OML CIVI Rail workholding system from Lexair, Inc. (Lexington, KY) boosts the productivity, accuracy and repeatability of horizontal machining centers, providing multi-part clamping in virtually limitless configurations on tombstones and trunnions. A unique V-jaw design pulls parts down against the parallels and a 60 deg angle on serrations provide more clamping surface for a sure hold on high-value parts. CIVI Rail can be used as a vise on existing machines, mounted vertically or horizontally on a tombstone or with a trunnion, providing flexibility and the ability to produce better parts, more efficiently.

The system includes interchangeable bases, moveable jaws and fixed supports. Bases are available in standards lengths from 10 in to 24.8 in (250 mm to 630 mm) and 2.4 in or 3.5 in (60 mm or 90 mm) widths, and include one fixed support. A 1.5 in (38 mm) jaw can be used on the 2.4 in (60 mm) rail for clearance around all sides of the part.

The CIVI Rail vise offers, as an option, the patented self-locking CLAK parallel system, with a dual-pin, ball-detent design, that snaps the parallels into place and keeps them there. The CLAK system allows for quick-change of parallels and jaws, making part changeovers and size changes quick and easy. Rail serrations are spaced 0.10 in (2.5 mm) apart for greater precision, and a scale machined into the side of the rail provides easy relocation of jaws and faster setups. Guarding and seals on the jaws keep chips and fluids out of the ramp system to protect system components. All components are precision hardened and ground.

Lexair is the exclusive importer and master distributor in the U.S. and Canada for OML, the Italian-based manufacturer of modular clamping systems, tombstones and precision vises.

Lexair, Inc., 2025 Mercer Road, Lexington, KY 40511-1018, 859-255-5001, Fax: 859-255-6656, www.lexairinc.com.

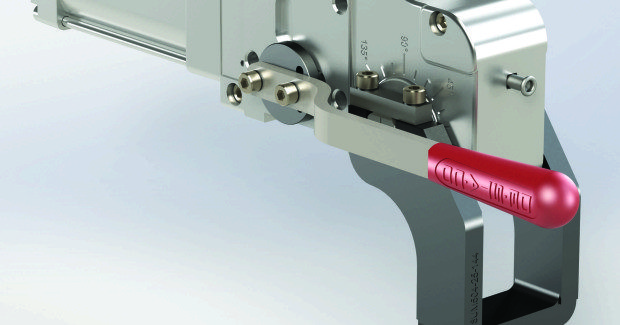

STRONG, VERSATILE ENCLOSED POWER CLAMPS

The new 82M-3E Series of enclosed pneumatic power clamps from DE-STA-CO (Auburn Hills, MI) provides automotive and sheet metal processing customers with superior holding power in a versatile, user-friendly and low-maintenance package. This full line of lightweight aluminum power clamps includes four sizes: 40 mm, 50 mm, 63 mm and 80 mm. The 82M-3E Series is well suited for a number of applications, including manual and automated fixture welding, positioning and locating.

All 82M-3E Series power clamps feature infinite arm opening adjustment with the industry’s greatest opening angle range: from 0 to 135 deg. This provides system integrators with maximum flexibility. The angle is easily adjusted in just seconds from behind the clamp. Not only does this patent-pending design feature save time, it also means 82M-3E power clamps require less space, allowing fixtures in which they’re installed to be lighter and more ergonomic than those equipped with other clamps. The 82M-3E’s sensors never need adjustment, even when the opening angle is changed, providing additional time savings.

Each of the 82M-3E Series clamps is available with a patent-pending hand lever on the right or left side for applications requiring manual loading. The levers feature the distinctive DE-STA-CO red handle and are adjustable for improved ergonomics. To provide long life with minimal maintenance, each 82M-3E Series clamp features an enclosed body, sealed needle bearings and a completely enclosed sensor to prevent the intrusion of dust or debris. Repairs are simplified by the sensor cartridge’s two-part design, which makes it possible to replace only the damaged component instead of the entire cartridge.

“Developing a new family of power clamps gave us the opportunity to step back and look at the product from the customer’s perspective,” explains Peter Schauss, the DE-STA-CO global product director for power clamps. “As a result, we’ve come up with a best-in-class series of clamps that is flexible and easy for integrators to set up, and that will perform for the end user customer over millions of cycles with minimal maintenance.” The 82M-3E Series is available worldwide and conforms to NAAMS and Euro mounting standards.

DE-STA-CO, 691 North Squirrel Road, Suite 250, Auburn Hills, MI 48326, 248-836-6750, Fax: 248-836-6743, www.destaco.com.

MODULAR CLAMPING SYSTEM REDUCES SETUP TIME; INCREASES MACHINE UTILIZATION

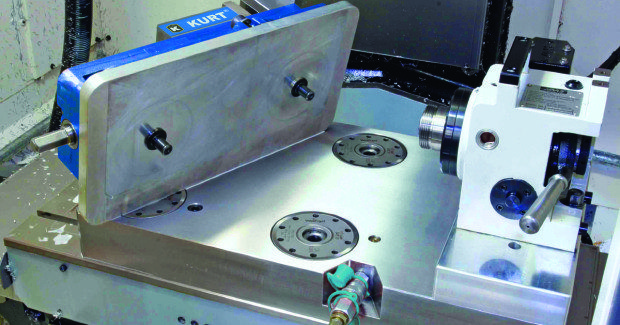

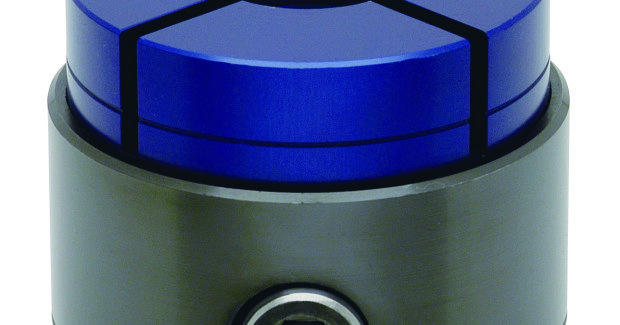

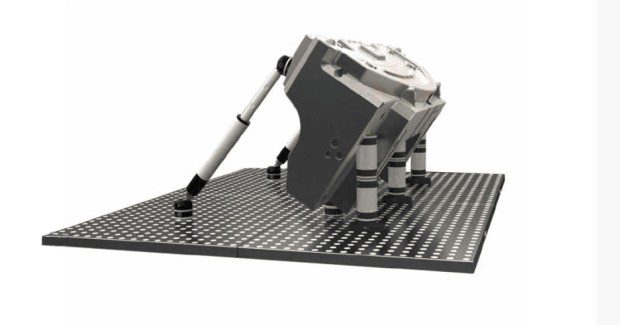

Single Source Technologies (SST; Auburn Hills, MI), a North American distributor of machinery brands such as Makino Inc. (Mason, OH), is pleased to announce the addition of the FCS Modular Clamping System (Breyl) to its product line. This unique clamping system provides unrestricted access to five surfaces of the workpiece and enables operators to spend less time on setups and more time on machining.

http://youtu.be/Ol_8m5JQXmw

An overview of the SST FCS Modular Clamping System.

“This modular system allows diverse fixturing options for any machining sector and turns hours of setup into minutes,” said Darrell Johnson, a product manager of milling consumables at SST. “Companies have reported increasing production time by 88 percent on average with this system, which translates into higher machine utilization and lower costs. Additionally, faster equipment and pallet changes mean a more standardized work process for improved part quality and consistency.”