Hardness Testers Packed with Innovative Technology

HM-200® Series Micro Vickers Hardness Testing Machines from Mitutoyo America incorporate the latest optical systems for measuring indentation dimensions together with an electromagnetic test-force loading device – just two of many productivity-enhancing technologies designed into these machines.

Posted: April 2, 2014

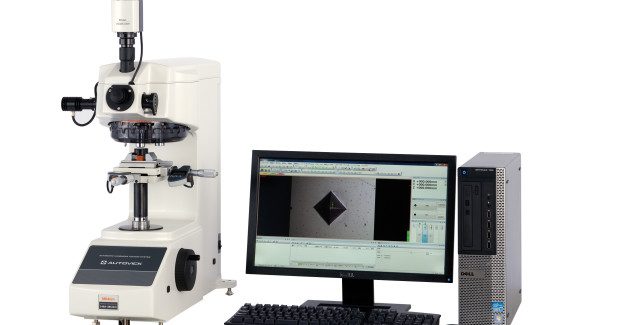

HM-200® Series Micro Vickers Hardness Testing Machines from Mitutoyo America Corporation (Aurora, IL) incorporate the latest optical systems for measuring indentation dimensions together with an electromagnetic test-force loading device – just two of many productivity-enhancing technologies designed into these machines.

Depending on model, these testing machines are equipped with a touch panel controllers and available CCD camera (System A) or with an included USB color mega-pixel vision system supported by AVPAK® software for automatic indentation measurement (System B).

HM-200® Series Micro Vickers Hardness Testers feature a motorized turret mechanism that automatically switches the position of indenter and objective lens via touch panel (System A) or from a PC running AVPAK® (System B); Systems A and B both allow manual switching of indenter and lens.

In addition, these testing machines can support output to measurement data applications such as MeasurLink®, Mitutoyo’s proprietary statistical-processing and process-control program which performs statistical analysis and provides real-time display of measurement results for SPC applications. The program can also be linked to a higher-level network environment for enterprise-wide functionality.

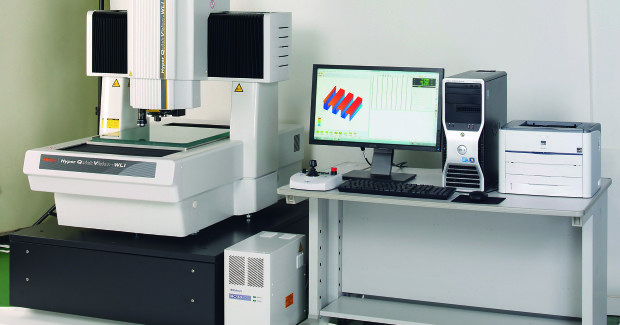

The company has also released the Quick Vision® WLI vision measuring machine. Besides an optical vision head, the Quick Vision® WLI also incorporates a white light interferometer (WLI) head. Together these heads enable high accuracy performance of non-contact vision plus non-contact 3D measurement of high aspect-ratio minute form (Z = Sub µm ~ 100µm) functions in a single machine – eliminating the need to move a workpiece from one type of machine to another.

A demonstration of how the QV-White Light Interferometry (QV-WLI) series combines all comprehensive functionality and optical performance of Quick Vision with high accuracy 3D topography evaluation in one machine.

As a result, the Quick Vision® WLI offers a significant throughput improvement for non-contact measurement of items combining both 2D and minute form 3D features in a single workpiece – example subjects could include IC chips and packages, hybrid chassis, lead frames, and many types of precision machined and molded parts.

The Quick Vision® WLI performs 2D/3D form evaluation using Mitutoyo FORMPAK-QV/FORMTRACEPAK-PRO software which features a refined, intuitive GUI. Results can be displayed in 2D/3D graphics for easy interpretation; a variety of editing and control tools are standard.

In addition, new Quick Vision® WLI 2D/3D non-contact measuring machines can support output to measurement data applications such as MeasurLink®, Mitutoyo’s proprietary statistical-processing and process-control program which performs statistical analysis and provides real-time display of measurement results for SPC applications. The program can also be linked to a higher-level network environment for enterprise-wide functionality.

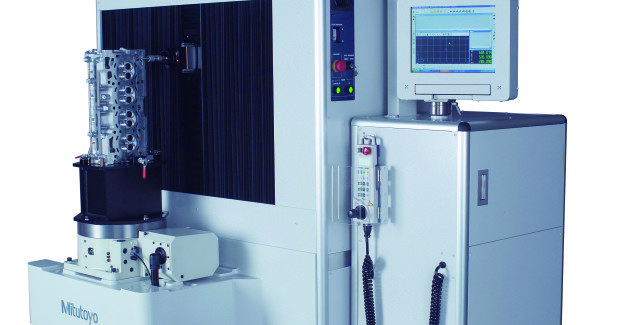

The company also announces availability of the MACH®-3A CNC Coordinate Measuring Machine – a CMM that brings levels accuracy and performance expected from Mitutoyo to in-line applications. Instead of the basic GO/NO GO judgments common to in-line gaging, the MACH®-3A CNC provides comprehensive measurements to enable statistical control utilizing numeric data. The MACH®-3A is a clean slate design embodying numerous features dedicated to functionality and high-performance for in-line applications.

The Mitutoyo MACH-3A 653 has been developed for high-speed manufacturing environments, making it the ideal replacement for mechanical gauges. It features a touchscreen interface and is compatible with a full range of Mitutoyo CMM products including; styli, jigs, loading systems and index tables.

The MACH®-3A CMM is a horizontal-arm type machine with high speed and high acceleration (max. speed of 1,212mm/s, max. acceleration of 11,882mm/s2 – both in vector direction) that contributes to high throughput for greater productivity and lower total owning and operating costs.

Conventional CMMs typically require dust-controlled environments to maintain accuracy. But with a drive unit protected by covers, precision linear guide systems for each axis instead of air bearings, and with its controller and PC installed in a dust-proof housing, the MACH®-3A is highly-resistant to the effects of dust, mist and humidity. The MACH®-3A also tolerates a wide range of operating temperatures – guaranteed to maintain accuracy between 5 deg and 40 deg C.

Additional production-oriented features include a machine status indicator (signaling machine fault or abnormal measurement), an ergonomically-positioned touch-panel monitor with built-in compact keyboard, plus a built-in, industrial-grade controller and PC. It all means this CMM offers the functionality, durability and stability required for 24/7 in-line operation.

The MACH®-3A CMM comes with standard with MCOSMOS® (Mitutoyo Controlled Open System for Modular Operation Support) which supports virtually every CAD format while providing routines for in-line measurement, data feedback, and process management. MACH®-3A architecture together with available Mitutoyo software packages make it easy to integrate this machine with high-level network environments for true enterprise-wide functionality.

Finally, now available is the innovative, new Ko-ga-me® measurement head – designed to bring full capability to applications where a compact, high-performance, 3D CNC, 2- or 3-axis measurement system would be ideal.

kogame-main_m

An overview and demonstration of Ko-ga-me and robot integration.

The Ko-ga-me® is small-sized, requiring only a minimal envelope (17.3 in [440 mm] x 16.1 in [410 mm] x 4.7 in [120mm]) and weighing 17.6 lb (8 kg). This makes Ko-ga-me® agile and easy to mount – using either an available fixed base (wherein the workpiece moves during measurement) or using a moving-axis mounting system of the customer’s own design.

Ko-ga-me® measuring systems are available for horizontal or vertical installation and can be used in stand-alone applications or integrated into work cells. Ko-ga-me® is ideal for inspection of large or small workpieces and offers a wide range of available measurement probes including touch-trigger, optical or constant contact probing.

Mitutoyo Corporation is the world’s largest provider of measurement and inspection solutions offering the most complete selection of machines, sensors, systems and services with a line encompassing CMMs (coordinate measuring machines), vision, form and finish measuring machines as well as precision tools and instruments, and metrology data management software.

Mitutoyo’s nationwide network of Metrology Centers and support operations provides application, calibration, service, repair and educational programs to ensure that our 6,000+ metrology products will deliver measurement solutions for our customers throughout their lifetime.

Mitutoyo America Corporation, 965 Corporate Boulevard, Aurora, IL 60502, 630-820-9666, Fax: 630-820-2614, info@mitutoyo.com, www.mitutoyo.com.