Hidden Danger: Laundered Shop Towels

Millions of workers may be exposed to potentially harmful metals by using laundered shop towels that retain measurable levels of metals after commercial laundering.

Posted: April 23, 2014

A peer-reviewed study conducted by Gradient Corporation (Cambridge, MA), a nationally recognized environmental and risk sciences consulting firm, shows that U.S. and Canadian manufacturing workers who use laundered shop towels may be exposed to lead and other metals.

The analysis, “Evaluation of Potential Exposure to Metals in Laundered Shop Towels,” was published in the October 2013 issue of Human and Ecological Risk Assessment.

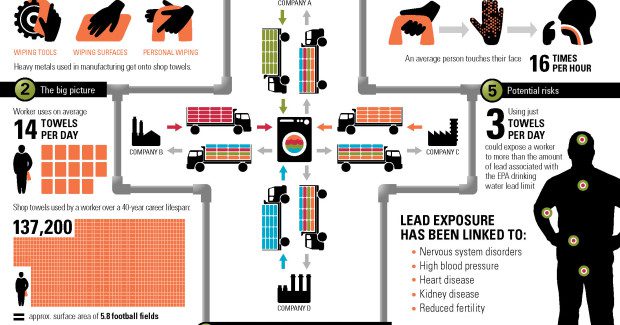

Workers cannot see, smell, or feel heavy metal residue on laundered shop towels, so the risk is not apparent to the many workers who use the towels to wipe parts, spills, and their hands. According to the U.S. Bureau of Labor Statistics, nearly 12 million Americans, or nine percent of the workforce, are employed directly in manufacturing. In Canada, more than one million people work in manufacturing.

In the study, exposure to metals by workers using laundered shop towels was estimated based on metal concentrations in towels and exposure modeling. The resulting exposure estimates were screened against recognized toxicity or regulatory criteria.

Based on the exposure assumptions employed in the study and the results of the towels tested, a worker using a typical number of laundered shop towels each day – an average of 14 – may ingest an amount of lead 400 times higher than the health-based criterion for reproductive effects set by the California Environmental Protection Agency (CalEPA) and more lead than that associated with the U.S. Environmental Protection Agency’s (EPA) action level for drinking water.

Additionally, he or she may be exposed to aluminum, cadmium, cobalt, copper, and iron at levels exceeding intakes associated with drinking water standards set by the EPA and other toxicity criteria set by the EPA and the Agency for Toxic Substances and Disease Registry (ATSDR). Workers with high-end exposures may be exposed to lead at levels up to 1,170 times higher than the CalEPA criterion for reproductive effects and 19.5 times more than the amount associated with the EPA action level for lead in drinking water.

Regulatory bodies such as the EPA and the Occupational Health and Safety Administration (OSHA) have long studied and regulated metals that may be consumed in drinking water or inhaled in the workplace, respectively. As is the case with laundered shop towels, the concern for workers’ exposure to chemicals and metals through inadvertent transfer of those substances from hands to mouth is rarely addressed in occupational literature.

Gradient estimated worker exposure levels for the towels tested based on current data regarding transfer of residues to hands, the number of towels workers used daily, and an approximation of the percent of towel surface area that came into contact with the hand. Transfer models allowed Gradient to estimate the movement of metals from towels to hands and then the mouth. Additionally, a scanning electron microscope imaging demonstrated the presence of heavy metal particles on the surface of the laundered shop towels; the particles were too small to be seen with the naked eye.

“The study adds to the growing body of data on potential health risks associated with using laundered shop towels in the workplace,” said Barbara Beck, PhD, DABT, FATS, and a principal at Gradient. “We continue to find a range of heavy metals on commercially laundered towels. Of particular interest is that exposures to lead may exceed certain health-based limits. Much as bacteria and viruses can spread through touch and be ingested, heavy metals on shop towels may also be transferred through touch to workers’ mouths and be swallowed.”

The study estimated worker exposure to 28 different metals in laundered towels collected from 38 U.S. and 16 Canadian companies, including printing, aviation, automotive, metal manufacturing, electronics, food and beverage packaging, chemical manufacturing and a range of other industries, as well as military plants. Metal exposure levels were then compared to toxicity criteria set by the EPA, ATSDR, and CalEPA, as well as drinking water standards established by the EPA. The EPA promulgates drinking water standards under the Safe Water Drinking Act to protect public health.

This study builds on a 2003 Gradient analysis showing that shop towels retain measurable levels of metals after commercial laundering and extends the findings presented in 2012 at the annual Society of Toxicology conference. It demonstrates that manufacturing workers using a typical number of shop towels may be exposed to metals such as lead and cadmium exceeding those allowed by the maximum contaminant levels or, in the case of lead, the action level for drinking water.

The research was funded by Kimberly-Clark Corporation (Irving, TX). The full study is available here.

Gradient is an environmental and risk science consulting firm with nationally recognized specialties in toxicology, epidemiology, risk assessment, product safety, contaminant fate and transport, and environmental chemistry. It assists national and global clients in resolving their complex problems relating to chemicals in the environment, in the workplace and in consumer products. Gradient’s principals and senior scientists are nationally recognized experts and active contributors to the promotion of sound science.