Intelligent Factories: The Fourth Industrial Revolution

A new era of highly efficient, flexible and customizable mass production requires software and analytical systems that turn the deluge of data produced by intelligent factories into useful and valuable information.

Posted: April 6, 2014

Enabled by communications and sensor technology, the global manufacturing business is on verge of what some are calling the fourth Industrial Revolution or Industry 4.0 — a new era of highly efficient, flexible and customizable mass production. However, Industry 4.0 faces a major challenge before it can live up to its promise, according to a new white paper from IHS Technology.

“The challenge for the fourth Industrial Revolution is the development of software and analytical systems that turn the deluge of data produced by intelligent factories into useful and valuable information,” explains Mark Watson, the associate director for industrial automation at IHS.

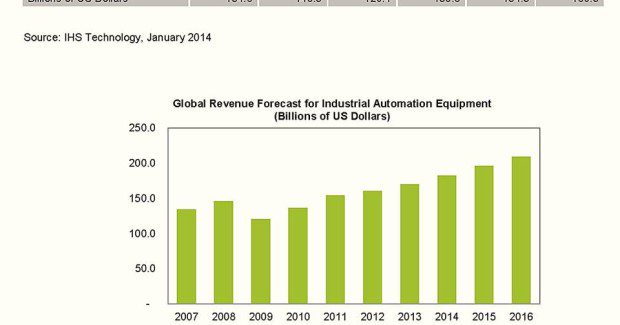

The potential stakes are enormous, with the global industrial automation industry amounting to $182.7 billion in 2014 and an expected $209.4 billion in 2016, as presented in the attached figure. “The term Industry 4.0 was coined by the German government to describe the intelligent factory, a vision of computerized manufacturing with processes all interconnected by the Internet of Things (IOT),” Watson said. “Some believe that Industry 4.0 is expected to spur fundamental changes on the order of the steam-powered first Industrial Revolution, the mass production of the second, and the electronics and proliferation of information technology (IT) that characterized the third.”

FLEXING INDUSTRIAL MUSCLES

Industry 4.0 carries many meanings, but early developments in this area have involved adding more flexibility and individualization to manufacturing processes.

Examples include electronics contract manufacturer Foxconn of Taiwan, which is producing 1 million iPhones per day for Apple. However, Apple makes frequent changes to electronic components in the iPhone line, taxing Foxconn’s capability to adjust. To be more flexible in order to fulfill demand from Apple, Foxconn is adapting its manufacturing lines and processes, making extensive use of computer numerical control (CNC) machine tools that perform automated management of processes.

Another example is from a leading food and beverage machinery provider, which is working on enabling the individualization of mass production by personalizing labels on the bottles of shampoo. Along with electronics manufacturers, IHS expects the food and beverage industry will be an early adopter of flexible, individualized manufacturing processes, Watson noted.

Another area where this approach is likely to find rapid acceptance is the auto-making industry, where manufacturers need to tailor their cars to the needs of individual customers.

DATA DUMP

With new industrial automation equipment increasingly integrating sensors and wireless communications capabilities, shops are now gaining the capability to gather sufficient data. While the penetration of wireless is currently very low, adoption will see a robust increase in job shops, contract manufacturers and steel service centers during the coming years.

But to achieve actual improvements in manufacturing efficiency and flexibility, these manufacturers must be able to manage and analyze huge amounts of data. Because of this, IHS predicts the biggest challenge in implementing individualized manufacturing systems will be on the software side.

One solution to this challenge may be distributed intelligence, i.e., making pieces of factory equipment intelligent and autonomous enough to determine on their own which pieces of information are valuable — and reporting that data to decision makers in the organization.

A CONTINUING REVOLUTION

In light of the challenge of big data and the need to implement new factory automation equipment, companies are likely to implement changes gradually over time. This will give organizations opportunity to develop expertise in managing and analyzing large amounts of data.

In some ways, the trend of manufacturers using technology to add flexibility to industrial processes has been ongoing for a number of years. Companies slowly have been adding more communications and data-gathering technology to their processes. Still, these trends are likely to gain momentum in the coming years, as the need for more individualized production increases.

IHS is a leading source of information, insight and analytics in critical areas that shape today’s business landscape. Businesses and governments in more than 165 countries around the globe rely on its comprehensive content, expert independent analysis and flexible delivery methods to make high-impact decisions and develop strategies with speed and confidence.

The firm has been in business since 1959 and became a publicly traded company on the New York Stock Exchange in 2005. Headquartered in Englewood, CO, IHS is committed to sustainable, profitable growth and employs approximately 8,000 people in 31 countries around the world.