Multitasking Machines

Here is a review of some of the latest multitasking machines that can mill, drill, turn, thread, bore, or groove complex, contoured parts during one setup and offer shops the competitive advantage they need in market applications ranging from aerospace, oil/energy and medical to construction and general purpose fabrication.

Posted: April 24, 2014

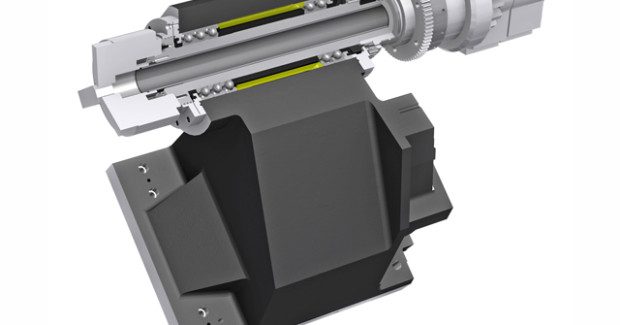

Precision axis movement with heavy loads is achieved by the use of hardened and ground wide box guide ways in all three axes. The wedge-type Y-axis design offers superior positional accuracy and is easy to program, which ensures increased productivity. X- and Y-axis travels are 8.3 in/3.9 in (210/100 mm); Z-axis travel is 22.8 in/19.7 in (580/500 mm). Rapid traverse: 709 ipm (18/12 m/min) in X- and Y-axis and 945 ipm (24/24 m/min) in Z-axis.

By enlarging the main spindle’s diameter and thickness and using only ultra precision class angular bearings, high speed accel/decel is achieved for smooth machining at high rpm. The main spindle delivers minimal noise and vibration even at the highest cutting speeds, guaranteeing extremely stable machining and minimizing thermal transmission to the main spindle. This contributes to improved durability and provides a high quality surface finish on every completed part.

Movement of the workpiece between the main spindle and sub spindle is performed in the rotating state by a synchronized control to reduce cycle times and increase productivity. Main and sub spindles are controlled with the C-axis. Contour machining with the C-axis is also possible, enabling the user to machine outer shapes and pockets, of complex parts, using live tools and the Y-axis.

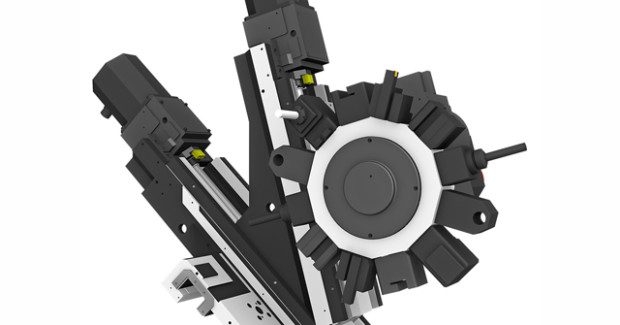

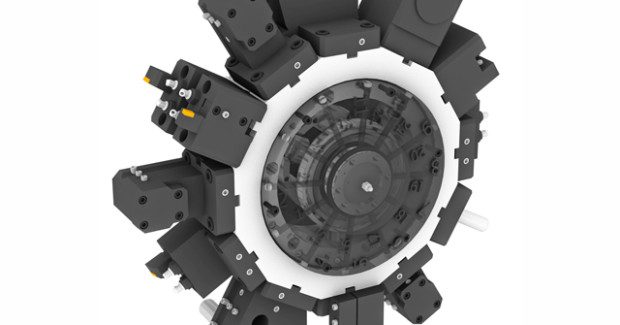

L2100Y/SY turning centers are outfitted with a large 12-station BMT turret, enabling these multitasking machines to perform high accuracy milling operations in a single setup. A high torque servomotor drives the BMT turret with a 0.4 sec indexing time in either direction. Overall cutting power and capability have been improved for all applications, including milling, drilling and tapping. Machining capabilities have been increased with the addition of a straight milling head, which removes material from the side of the workpiece, and an angular milling head, which allows ID operations.

The L2100Y/SY Series is easy to program and operate with its state-of-the-art Fanuc 32i-A Series CNC control featuring a 10.4 in color LCD with Manual Guide i. As the industry’s most popular control, Fanuc offers compatibility and bulletproof reliability. The L2100Y/SY Series is ideal for small to medium sized job shops, yet capable enough to handle high production environments that run 24/7. By bundling so many high-performance features in a CNC multitasking turning center, there’s nothing to sacrifice or compromise.

Hyundai WIA America Corporation, 450 Commerce Boulevard, Carlstadt, NJ 07072, 201-636-5640, Fax: 866-906-1255, www.hyundai-wiamachine.com.

COMPACT MULTITASKING MACHINE FOR MASS PRODUCTION

The Brother M140X1 from Yamazen Inc. (Schaumburg, IL) works best in mass-production parts processing. This compact, multitasking machine has an added a trunion-style turning function in conjunction with Brother’s high speed mill and tapping. Workpieces previously machined using a turning center and a machining center are now combined into one machine, thereby reducing handling time between machines. The newly developed high-speed and high-output built-in DD motor produces more efficient turning with a maximum speed at 2,000 min-1.

A demonstration of the compact Brother M140X1 multitasking machine.

To see a demonstration or learn more about Brother’s M140X1contact your local Yamazen sales representative or call toll free.

Yamazen Inc., 735 East Remington Road, Schaumburg, IL 60173, 800-882-8558, corporate@yamazen.com, www.yamazen.com.

IDEAL MULTITASKING OF SMALL COMPLEX PARTS

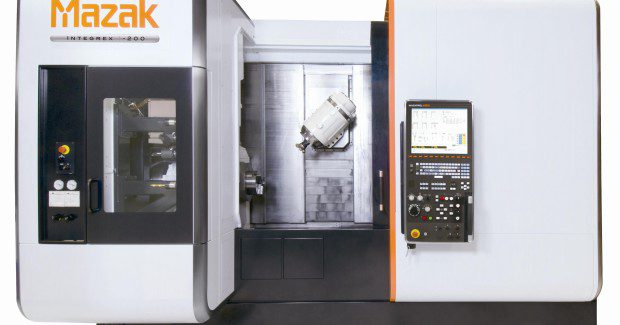

Perfect for processing small complex parts, the compact INTEGREX i-100 BARTAC-S Multitasking solution from Mazak Corporation (Florence, KY) employs a large 4.4 in spindle bore to bring high levels of productivity to the machining of bar material up to 4 in diameter.

http://youtu.be/-EwYzw6FZK8

A demonstration of the INTEGREX i-100 BARTAC-S machining system.

With a small footprint of 127 in x 98 in, the INTEGREX i-100 BARTAC-S requires minimal floor space when compared to conventional equipment with gantry loader or robot systems with a footprint. Other machine characteristics include:

- Large 4.4 in spindle bore efficiently machines large bar material.

- Second turning spindle (S) enables Done-In-One operations.

- Intelligent Bar Loader System productively handles bar material.

- 36-tool and 72-tool magazines feature automatic tool changers.

- MATRIX 2 CNC Control provides optimized 5-axis machining.

- Intelligent Functions offer ease of operation and optimum efficiency.

- Accommodates optional integrated work unloader and conveyor that cost effectively handles completed workpieces from the second spindle.

Mazak also offers the Vertical Center Universal 400 5X that incorporates a 5-axis rotary/tilt table to cost effectively process small complex parts; the INTEGREX i-200ST multitasking machine with twin turning spindles, a lower turret and milling spindle to process mid-size complex parts in single setups; and the Quick Turn Nexus 250-II MY multitasking turning center that features an upper turret with a rotary tool spindle and Y-axis functionality to efficiently perform milling, turning and drilling operations.

http://youtu.be/4P97NZP9bYc

A demonstration of the Vertical Center Universal 400 5X.

The Vertical Center Universal 400 5X features a 5-axis rotary/tilt table with durable, high-speed roller gear cam technology to productively process small complex parts up to 400 mm x 400 mm x 250 mm in size.

The INTEGREX i-200ST multitasking machine accurately processes mid-size complex components up to 658 mm diameter in single setups. For C-axis contouring versatility at either turning spindle, the machine’s vertically mounted 12,000 rpm milling spindle provides a rotating B-axis range of -30 deg to +240 deg. The nine-tool lower turret works in combination with the milling spindle that users can apply to either side of the machine headstock.

The Quick Turn Nexus 250-II MY multitasking turning center features an upper turret with a rotary tool spindle and Y-axis functionality to perform milling, turning and drilling operations in maximum machining diameters of 380 mm. The machine’s headstock features a 254 mm chuck mounted on a 26 kW, 4,000 rpm integrated motor main turning spindle for heavy-duty metal removal. The spindle also acts as a C-axis as it is capable of indexing in 0.0001 deg increments to accurately position parts for square facing and slotting cuts as well as precisely drilled holes. The C-axis spindle is a full-function CNC controlled axis for milling.

Mazak Corporation, 8025 Production Drive, PO Box 970, Florence, KY 41022-0970, 519-658-2021, rbuxton@mazakcorp.com, www.mazakcorp.com.