Siemens Names TechSolve as a Solution Partner for MTConnect

Through this development, Siemens proactively responds to the growing demand in the market for MTConnect solutions among the end-user and machine tool builder sectors.

Posted: April 9, 2014

During this year’s [MC]2 2014 MTConnect: Connecting Manufacturing Conference, Siemens Industry, Inc. (Elk Grove Village, IL) announced today the appointment of TechSolve (Cincinnati, OH) as a Solution Partner to offer solutions to customers with Sinumerik CNCs who are interested in or have already implemented MTConnect into their factories.

Through this development, Siemens proactively responds to the growing demand in the market for MTConnect solutions among the end-user and machine builder sectors. TechSolve was a Founding Sponsor of the MTConnect Institute and is a major supplier of MTConnect Adapters and translation products, as well as support software and services that enable shops and production departments alike to more efficiently gather and analyze machine tool performance data, using the open-source communication standard of MTConnect.

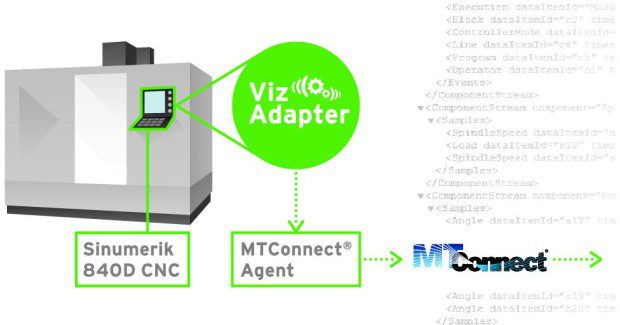

In a typical machine tool end-user scenario, TechSolve applies its Adapter software to an existing machine’s CNC, such as the Siemens Sinumerik 840D, which enables data transfer through an MTConnect Agent. For older controls and legacy devices that do not have native communication output, TechSolve can also supply additional hardware and communication software to facilitate this process. The data can then be stored locally or cloud-based for further access and evaluation in an overall equipment effectiveness (OEE) strategy.

Likewise, TechSolve provides Adapter software to machine tool builders for integration into their control schemes to suit particular applications or customer-mandated specifications for MTConnect compatibility.

Ryan Legg, the product manager of Sinumerik CNC, Siemens Industry, Inc., explains, “In the U.S. market especially we are seeing growing demand for MTConnect. This appointment of TechSolve as a Solution Partner to support requests for MTConnect represents our company’s commitment to bring practical solutions to our customers through an experienced and reliable source of both products and services. When MTConnect is written into the specification on any job, we now have an ideal resource to complement our capabilities.”

Noting how the open architecture of the Siemens CNC allows easy integration of the TechSolve solutions; Legg further explains the cross-platform advantages of this new relationship. “TechSolve has written their MTConnect Adapter for the Sinumerik CNC in a way which allows complete flexibility regardless if the system architecture of the Sinumerik employs a PCU or if it is running in an embedded architecture without a PCU,” he says. “Ultimately, this allows for more customers to take advantage of this offering.”

Ron Pieper, the manager of VizProducts™ Group at TechSolve, observes, “To be affiliated with Siemens is a compliment to both of our products and services as well as our engineering talents. We believe this relationship will be mutually beneficial, as it will further promote the acceptance of MTConnect in the machine tool market, plus being a Solution Partner to Siemens will open new doors for our company.”

Pieper further comments on the market need for these solutions. “When all the data from the shop or factory floor is available as it occurs, the customer learns the reality of their situation and then can make confident steps to improve their game, so to speak. They see where the inefficiencies are, where and why the downtime is occurring and how they might improve or streamline production. All of these factors are crucial in today’s competitive machining market.”

More information on the above-mentioned solutions is available at the MTConnect Conference being held in Orlando that is organized by the MTConnect Institute.

www.usa.siemens.com/techsolve-pr