Taylor-Winfield Solves AHSS Welding Issue for World’s Largest Steel Producer

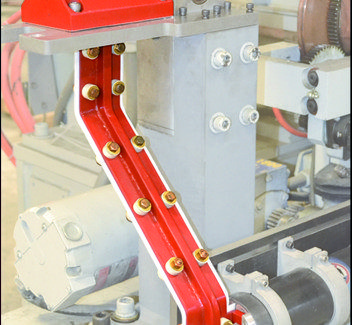

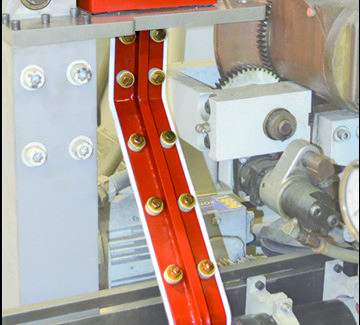

The AnnWeld™ post-weld induction annealing system is integral to the welder and mounted in-line with seam welding systems or as an additional process step for flash welders to improve ductility in the welded joint without sacrificing weld strength, which prevents weld breaks during subsequent line processes.

Posted: April 21, 2014

The world’s largest steel producer selected Taylor-Winfield Technologies, Inc. (Youngstown, OH) to integrate Post-Weld Induction Heating Systems into their existing seam and flash welders.

Today’s increasing demand for Advanced High Strength Steel (AHSS) grades is leading steel producers to find ways to expand the range of materials capable of being joined by existing coil joining welding machines. In response, Taylor-Winfield developed the AnnWeld™ post-weld induction annealing system for seam and flash welders.

The system is integral to the welder and mounted in-line with seam welding systems or as an additional process step for flash welders. The process improves ductility in the welded joint without sacrificing weld strength which prevents weld breaks during subsequent line processes. Full integration is available for existing Taylor-Winfield and/or any other manufacturer’s welders.

Taylor-Winfield has manufactured induction heating equipment and systems since the 1950s. Their Ther-Monic brand of induction heating power supplies range from 1 kW to 1 MW, with frequency ranges from 3 kHz to 6 MHz with custom engineered coils and systems available. The expertise to join and temper AHSS grades was developed in Taylor-Winfield’s Research & Development Laboratory in collaboration with several major steel producers.

The AnnWeld™ system includes accurate and repeatable heat cycles, precision temperature control using pyrometer feedback, automatic load tuning, and custom manufactured coils sized for use with existing welders. The AnnWeld™ system is designed for customer requirements and can be used with any welder in any process line.

mkeller@taylor-winfield.com, www.taylor-winfield.com