Tier 2 Automotive Supplier Retrofits Tailout Feeders for Coil Lines

COE Press Equipment retrofit the equipment to three coil lines feeding 500 ton progressive die presses for ARJ Manufacturing.

Posted: April 30, 2014

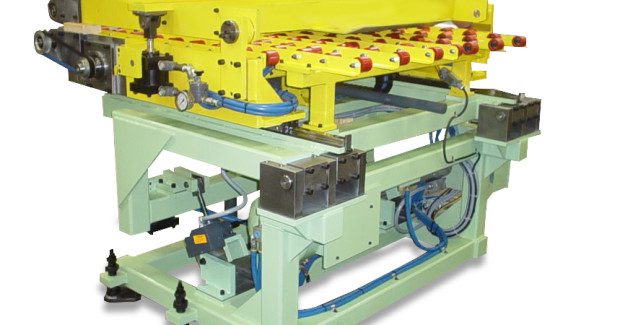

COE Press Equipment Corporation (Sterling Heights, MI) has recently retrofit tailout feeders to three coil lines feeding 500 ton progressive die presses for Tier 2 automotive supplier ARJ Manufacturing LLC (Frankin, TN).

Floor-mounted in the safety zone between the press and the existing servo-feeds, the tailout feeders, also known as secondary feeders, can retract to a size of 38.5 in during die changes, but then extend up to 56.25 in for close positioning to the die when the line is running. By closing up this gap, less material is wasted.

Primary coil feeders must be positioned out of the press column area and remain within the safety zone in order to accommodate the room needed to roll in bolsters for a die change. At the ARJ facility, this positioning was resulting in a significant gap between the feeders and the die, causing excessive scrap, handling issues and productivity loss at the end of the coil. The tailout feeder’s ability to retract and extend solved this problem and provided ARJ with increased flexibility, safety and material savings.

COE designed the stand-alone tailout feeders to retrofit within the space downstream from the primary coil feeder. The feeder extension is operated through a motorized screw assembly. During normal operation the primary feed indexes the coil into the die. Once the tailout sequence is initiated, the secondary feeder takes over the feed cycle.

The upper rolls of the feeder are 96 mm in diameter, and can be raised and lowered via air cylinders. The lower driven roll is 127 mm diameter – all the rolls feature a #3 matte chrome coating. Each of the new feeds can handle coil up to 5.00 mm thick and up to 500 mm wide or 0.8 mm thick at up to 1000 mm wide, and are equipped with a ServoMaster Touch controls package.

COE also recently upgraded coil feed lines with its ServoMaster Touch Control package for water heater manufacturer Bradford White (Middleville, MI). The retrofits were performed on two ServoMaster Series 3 roll feeds that were originally installed in 1999. Since purchasing this equipment, Bradford White acquired two new COE lines, which led to a decision to standardize on all the controls for efficiency gains.

The ServoMaster Retrofit Package includes complete replacement of the operator interface, controls console, servo motor, cable sets and pneumatic valve. This upgrade provides Bradford White with the most current digital drive packages and operator interface. Features of the upgrade include streamlined entry of machine set-up information and enhancements to the operator prompts, machine diagnostics, and serial communications to the press controls – all which contribute to easier use and faster setup.

Additional capabilities include production data reporting of feed cycles and material usage, and downloading of set-up data or job number selection. Its multi-axis capabilities include push-pull, zig-zag and tailout configurations. Auxiliary functions achievable through the Servo Feed Automation Feature include motorized and encoded passline height, motorized and encoded automatic edge guides, feed roll pressure control and material support table position.

The ServoMaster Touch Controller comes complete with everything necessary for a weekend upgrade. Six different drive sizes are available to meet varying torque and speed requirements for servo feeds up to 8 in diameter and 78 in width. Benefits include improved job set up times, increased production rates, part accuracy and serviceability. Additionally, COE will provide any necessary training on the new controls.