How Well Do You Know the Capabilities of Your Punch Machine?

Are you missing opportunities to produce parts profitably? Which of your parts currently require two or three machines to produce a completed piece? Let’s consider how you might put more profit in your pocket by producing those same parts with just your punching machine.

Posted: May 27, 2014

If you use your punching machine just to punch holes, or consider it the noisemaker in the corner, used once a week for the one job you still can’t justify running on a laser, then you are missing opportunities to produce parts profitably. And if you think you can’t use your punch machine because your parts are cosmetic and must be free of scratches, nibble marks, or burrs, you need to think again.

Today’s punching machines are technologically advanced. New machine capabilities make it easy for manufacturers to make a complete part with bends, forms, shear edge quality, and with a finish that is free of scratches or burrs without any secondary operations. To many fabricators this seems impossible but here, we consider ways to accomplish these feats and put more profit in your pocket.

SCRATCH FREE PROCESSING

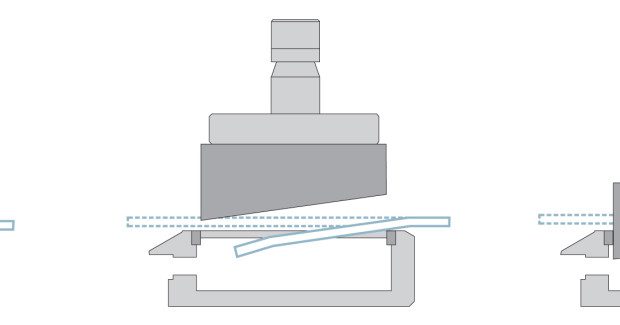

Scratch-free part processing is accomplished by lowering the die as the sheet is moved into position. To achieve this, the tools must be off the material when they are exchanged and only one tool may be in contact with the material at any time. Brush tables also help to eliminate scratches or marks on the part or material. As an added benefit, the tables also reduce noise as the material is moved back and forth under the punching head. To further minimize noise, a fabricator can grind an angle or shear edge on a tool so it is able to drive through the material with greater ease during the punching process.

SHEAR CUT EDGES

New tooling developments have made it possible to achieve shear cut edge quality directly on the punching machine. Edges can be made at any angle and used for internal or external geometries in material up to 0.120 in thick. Unlike conventional punch press processing methods, the tool leaves no nibble marks on the edge of a part. Instead, it acts like a pair of scissors as it cuts through the material to provide a clean quality edge. A burr does remain on the bottom of the part after the punching or shearing process, but it can be compressed or coined back into the material by chamfering the edge. The process is similar to a countersink or counter bore process and provides consistency of the chamfer from part to part.

A demonstration of the capabilities of the TRUMPF TruPunch 5000.

IN-PROCESS OPERATIONS

The latest punching technology also enables new in-process operations to be completed on the machine to minimize or eliminate secondary operations and increase the range of possible applications. Greater clearance between the punch and die has made it possible to achieve higher forms on a punching machine. Larger forms are generated by lowering the die to force the material off the form instead of using an ejector integrated into the tool.

Small parts with short bends can be time consuming and cumbersome to produce on a press brake. Single hit forming flanges up to one inch high and three inches long can be produced on a punching machine to eliminate the secondary operation on a press brake. The flanges can be produced at any angle, both on internal and external geometries of the part. They can also be incorporated with other operations, such as tapped holes, shearing operations and deburring features.

Roll form tapping operations are a popular task for fabricators to complete on the punching machine. Tap size threads up to 3/8 in or M10 can be completed in three seconds on average. Fabricating hinge forms on a punching machine eliminates the need for welding the form as a secondary operation. It also eliminates the need for fixtures or alignment devices since a hinge knuckle up to one inch wide and a 0.250 in inside diameter hinge can be produced directly on the machine.

PART MARKING

There are a variety of ways to mark a part using a punching machine. The best solution depends on a fabricator’s specific needs and requirements. Scribing tools can create any letter, number, or geometry, but typically are not the best solution when coatings are applied to the part after the marking process is complete. Dot matrix marking is a high speed process where the punch head delivers up to 2,800 spm and the depth of the stroke can be adjusted to 0.001 in increments. The same is true for sharp face characters. By placing various numbers or letters in a multiple punching head tool, sequential numbering or alphabetizing can be completed quickly and easily. This part marking option can be coated after the parts are processed, and stamping process will remain legible.

With this in mind, I now challenge you to take a look at your own parts. Find those which currently require two or three machines to produce a completed part, and then consider how you might produce the same parts with just your punching machine. The result will be faster and more cost effective production.