New Software Makes Fabrication of Pressure Vessels, Spools and Nozzles Easier

With HGG ProShell Software from HGG Profiling Equipment, shops can easily import part program files from CAD/CAM design systems, design product profiles and profiling information, view 3D profiles and efficiently divide them into available raw materials for nesting.

Posted: June 25, 2014

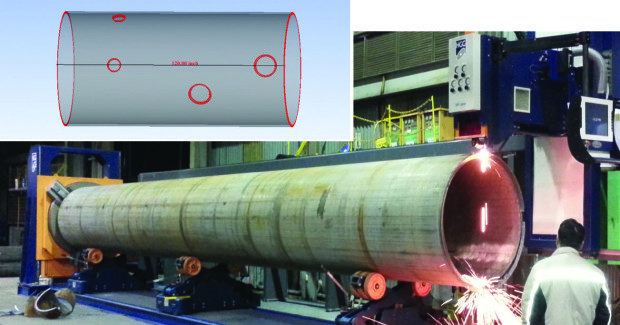

New HGG ProShell Software from HGG Profiling Equipment (Charleston, SC) complements HGG Pressure Vessel Machinery. The comprehensive software package facilitates the design and fabrication of pressure vessels, spools and nozzles. With it, users can easily design product profiles and profiling information in MDI, view profiles with a 3D viewer, and then efficiently divide them into available raw materials for nesting. Users can also import part program files from CAD/CAM design systems.

The ProShell Software package provides an ideal interface for the export and conversion of entire part program files (pressure vessels, spools and nozzles) modeled from various CAD packages into CNC data files without the need for additional processing, while supporting additional editing features.

Plus, with the software feature called “building information model,” pressure vessel manufacturers are able to enrich information through the standardization of all aspects of industry, from design to production to the final product. Along with the ProShell Software package, chuck-style HGG Pressure Vessel Machines combine plasma and oxyfuel processes for 3D steel-profile cutting capability. They eliminate the need for laying out lines on shells, grinding a bevel, as well as additional welding after the holes are cut to provide a perfect fit-up.

An introduction and overview of the compact ProCutter (PC600) pipe cutting and profiling machine for cutting complex shapes.

Manufacturers can improve production capabilities while reducing manufacturing cycles. Chuck-style HGG Pressure Vessel Cutting Machinery includes the PC-600 Pipe Cutting Machine for cutting smaller vessels, nozzles and spools; eight SPC-Series Machines for cutting a wide range of diameter sizes of vessels, spools and nozzles; and the hybrid SPC-1200-RB that combines the precision of a chuck-based HGG cutting machine with a material handling roller-bed for maximum productivity and automation.

HGG, headquartered in Wieringerwerf, Netherlands, is an international supplier of pipe cutting machines, robotic profile cutting lines and associated cutting equipment solutions. HGG Profiling Equipment is a subsidiary in Charleston that provides comprehensive sales and service support for the company’s growing customer base in North America, Central America and South America.

HGG Profiling Equipment serves an array of industry customers in Steel Construction, Piping Process Industries, Offshore/Onshore, Crane Building, Ship Building and others.

HGG Profiling Equipment, 5519 Indigo Commons Way, Charleston, SC 29418, 330-461-6855, jt@hgg-group.com, www.hgg-group.com.