Pipeline Welding & Fabrication

As the need for specialty steel pipe grows, higher steel grades and bigger wall thicknesses are introducing new challenges to pipe welding and fabrication shops. Here are some of the latest advances in welding equipment and fabrication tools that can help these shops gain and maintain a competitive advantage.

Posted: June 3, 2014

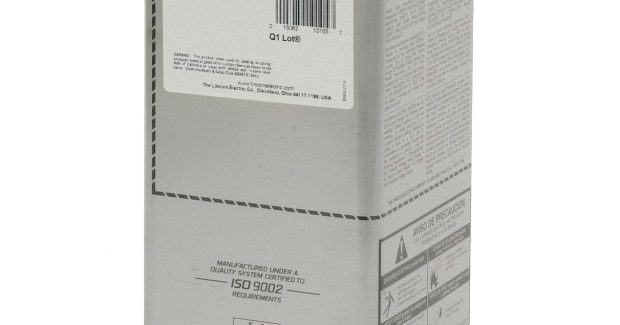

The company also offers introduces a low-alloy stick electrode to the SMAW Pipeliner® Portfolio – Pipeliner® Arc 80, designed for root pass welding up to X80-grade pipe, and fill and cap pass welding for X70-grade pipe. Pipeliner Arc 80 is classified as E8010-G and E8010-P1 per AWS, and has the same AWS classification as Shield-Arc®70+ and Pipeliner8P+, without the intentional addition of boron. This allows for a variety of choices based upon the application and operator needs. Key features include:

- High productivity in vertical down and out-of-position pipe welding

- Deep penetration

- Q2 Lot® control showing actual deposited chemistry

- Clean, visible weld puddle

- Superior puddle control

The Lincoln Electric Company, headquartered in Cleveland, OH, is a world leader in the design, development and manufacture of arc welding products, robotic arc welding systems, fume control systems, plasma and oxyfuel cutting equipment and has a leading global position in the brazing and soldering alloys market.

The Lincoln Electric Company, 22801 Saint Clair Avenue, Cleveland, OH 44117-1199, 216-383-2462, Fax: 216-383-8381, www.lincolnelectric.com.

FIRST INDUCTION TECHNOLOGY FOR PREHEATING IN ROLLED PIPE WELDING

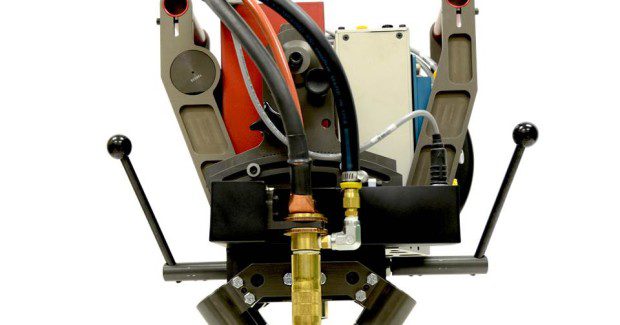

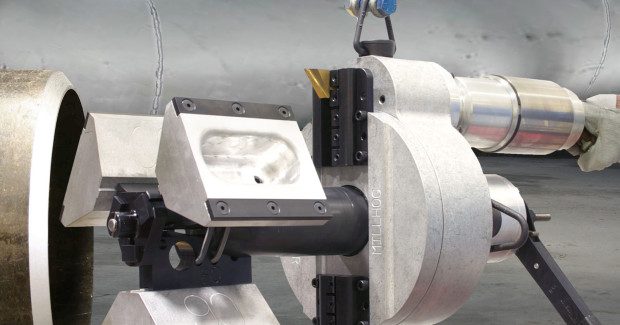

Miller Electric Mfg. Co. (Appleton, WI) introduces the ProHeat™ 35 Rolling Inductor — a highly efficient, industry-first induction technology for preheating in rolled pipe welding applications. When connected to the Miller ProHeat 35 induction heating power source, this system provides pipe fabrication shops with increased productivity, improved safety and consistency in heating.

An overview and demonstration of how the ProHeat™ 35 Rolling Inductor from Miller Electric operates.

“Many ASME-certified shops weld pipe spools for the refinery, petrochemical, power and HVAC industries and the majority of those jobs are roll welded for improved productivity, said Kristi Endries, the heating solutions specialist for Miller Electric. “However, rotating pipe while welding limits a welding operator’s options for preheating and maintaining interpass temperatures to non-electrical methods, such as flame. The ProHeat 35 Rolling Inductor solves these issues by combining the benefits of rotating pipe and electrical preheating into one.”

Pipe assemblies that are chrome alloy, heavy wall or stored in cold environments require preheating because of code and quality control requirements. Jobs that benefit from rolling induction technology include applications using carbon steel that is colder than 50 deg F, carbon steel over 1 in thick; or any chrome alloy steels. Compact and portable to configure around various pipe sizes throughout the shop, the ProHeat 35 Rolling Inductor is highly efficient and extremely accurate for increased productivity. Quick time to temperature increases production times while reducing consumable costs and labor expenses. This non-contact method of heating while rolling the pipe assembly also eliminates wrapping cables and allows for continuous fabrication.

The ProHeat 35 Rolling Inductor and its hinged arm are mounted on a standard pipe stand, allowing the welder operator to easily align the induction head on the top or side of the pipe. The power source then recognizes the attachment, so users must only set maximum output and time. The Rolling Inductor can easily be removed from or put back on to the pipe, mirroring the simplicity of turning a torch on or off. Because the ProHeat 35 Rolling Inductor sits directly on the rotating pipe and provides steady, continuous output, hot and cold spots are eliminated, minimizing risks of weld failure due to cracking.

The Rolling Inductor greatly improves efficiency versus flame heating, because the heat is generated within the part. Direct heat transfer also results in a cooler shop environment and reduced fume levels. Elimination of open flames significantly reduces burn potential and welder fatigue, as well as the need to store explosive gases used for heating. In addition to induction technology used while rolling pipe, the ProHeat 35 power source is capable of other applications including hydrogen bake out, shrink fit and post-weld heat treatment.

Miller Electric Mfg. Co., headquartered in Appleton, is a leading worldwide manufacturer of Miller brand arc welding products and is a wholly owned subsidiary of Illinois Tool Works Inc. (ITW).

Miller Electric Mfg. Co., P.O. Box 100, Lithonia, GA 30058, 800-426-4553, Fax: 877-327-8132, info@millerwelds.com, www.MillerWelds.com.

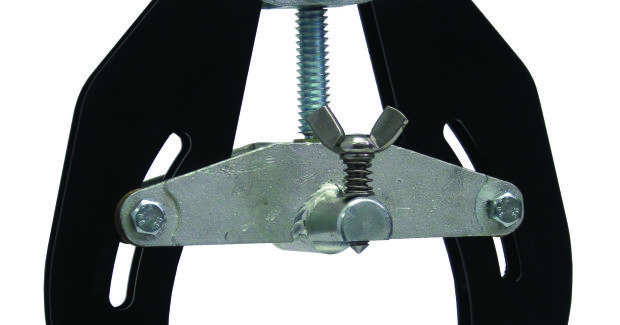

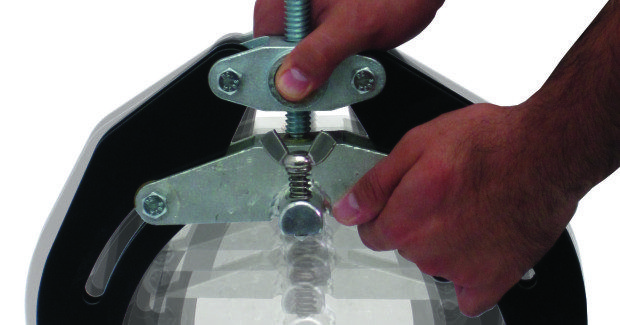

CLAMPS AND TOOLS FOR PIPE WELDING FIT-UPS

Sumner Manufacturing Co., Inc. (Houston, TX) offers the Ultra Qwik Clamp and Ultra Qwik Fit that are based on the highly popular Ultra Clamp and Ultra Fit tools for pipe-to-pipe, pipe-to-fitting, pipe-to-flange and fitting-to-fitting pipe welding fit-ups. Both the Ultra Qwik Clamp and Ultra Qwik Fit feature push-button thread adjustment, a feature that allows users to quickly size-adjust the clamps with the push of a button.

A demonstration and overview of the Ultra Qwik Clamp for Pipes from Sumner.

Holding the push-button in on the tool housing frees the threading to be adjusted at will to the correct size. Releasing the button allows the user to fine adjust and tighten the tools in the same manner as the Ultra Clamp and Ultra Fit. The push button thread adjustment feature was successfully introduced with Sumner’s Hold-E pipe clamp for standard vee head jack stands.

The Ultra Qwik Clamp and Ultra Qwik Fit accommodate three sizes of pipe: 1 in to 2-1/2in (25 mm to 65 mm), 2 in to 6 in (50 mm to 150 mm) and 5 in to 12 in (127 mm to 300 mm). The Ultra Qwik Clamp and Ultra Qwik Fit have the same lightweight design and a rugged frame built for job site use as the Ultra Clamp and Ultra Fit. Stainless steel alignment screws at all contact points hold fittings in place and allow for fine adjustment. Smooth roller clamping action enables positive gripping and the operating handle repositions for close work. Fit-up settings can be maintained for repeat fit-ups.

Sumner has also upgraded their lightweight, portable and easily assembled all-aluminum GH2T Gantry Lift. The GH2T Gantry lift has a lift capacity of up to 2 metric tons (4,400 lb) and is available in four Imperial sizes (8 ft, 10 ft, 12 ft and 15 ft) and three Metric sizes (3 m, 4 m and 5 m). Upgrades to the GH2T Gantry include A-frame legs that lock in opened or closed position utilizing a push-button release and casters with foot brake that lock at 90 deg angles. The new design of the A-frame assembly eliminates the need for a locking cross bar to hold legs in the open position.

A demonstration of the assembly of the Sumner GH2T Gantry lift.

The trolley features a set screw that when tightened to the beam holds it in place during assembly, and a convenient positioning handle. The trolley weighs approximately 15 lb (6.8 kg). Cross beams come in seven sizes (8 ft, 10 ft, 12 ft and 15 ft; 3 m, 4 m and 5 m) and have nylon carrying handles at both ends. Both 5 m and 15 ft beams feature two span adjustments on either end of 13 in (33 cm). The 8 ft beams have no span adjustments. The GH2T Gantry assembly is specifically designed to be erected by a two-man crew.

Minimum and maximum heights from ground to lifting eye are 83 in (2.1 m) and 113 in (2.8 m) respectively. Maximum height to the top of the trolley is 113.5 in (3.4 m). The maximum width of the A-frame when erected is 60.75 in (1.54 m). The stored height of the A-frame is 100 in (2.5 m). Gantry models weigh between 285 lb and 331 lb (146.5 kg and 129.2 kg).

The company also offers the Sumner Fat Jack with beefier construction, including 1-1/4 in square tube base construction and double 3/8 in diameter locking pins. This improved construction, along with the existing 12-1/2 in (31.8 cm) wide ribbed vee head, increases this folding jack’s capacity from 2,500 lb (1,135 kg) to 5,000 lb (2,270 kg). The Fat Jack is also available with a roller head that maintains a capacity of 2,500 lb (1,135 kg).

Founded in 1965 in Houston, Sumner Manufacturing has served the welding and mechanical contracting industry for nearly a half century, creating high quality material lifts, jack stands, pipe fit-up clamps, welding tools, and material carts that are currently used daily in more than 50 countries around the world in numerous industries. All Sumner products are built with the concept of providing safe, common sense tools which are priced right. Sumner Manufacturing maintains offices in Houston, TX, Canada, China, the UK and the Netherlands.

Sumner Manufacturing Co., Inc., 7514 Alabonson Road, Houston, TX 77088, 281-999-6900, Fax: 281-999-6966, www.sumner.com.

TOOLS FOR ACCURATE PIPE WELD PREPS AND CUT TIME ESTIMATES

Project managers, welding contractors, and field machinists will find that they will make their pipe welding more efficient by using weld prep tools. Quality, precision weld preps made with E.H. Wachs (Lincolnshire, IL) equipment ensures users that the welding process will consistently pass inspections time and time again, while avoiding any reprocessing of the weld prep. Wachs machine tools are built to cut, bevel, j-prep, counter bore, flange face and single point pipes from 2 in to 72 in OD and utilize a cold cutting process that eliminates the hazards related to torch cutting and grinding. This is especially important wherever volatile hydrocarbons are present.

Available online at ehwachs.com/calculators, Wachs offers online time calculators and other tools to help prepare cost estimates when bidding on pipe maintenance or pipe repair projects. Utilizing these tools, managers, contractors and machinists can better estimate labor time with the Pipe Cutting and Weld Prep Time Calculators. To see a video on how they work, go to youtube.com/ehwachs or this direct link at http://youtu.be/5rmnohfOmN0.

A long time industry favorite, Wachs cold cutting weld prep equipment products include the Low Clearance Split Frame (LCSF); Small Diameter Split Frame (SDSF); Heavy Duty Split Frame (HDSF); Guillotine® Pipe Saws; Trav-L-Cutter®; EP424 End Prep Machine; FF series flange facers; SDB small diameter bevelers; boiler tube bevelers; handheld valve operators; hydraulic power units and Genuine Wachs Tooling. E.H. Wachs equipment is available as rentals for short term needs. Wachs products are available at our strategically located Sales, Service and Rental Centers and though our worldwide dealer network.

E.H. Wachs®, 600 Knightsbridge Parkway, Lincolnshire, IL 60069, 847-537-8800, info@ehwachs.com, www.ehwachs.com/Industrial-Products.