How to Model Machining and Sheet Metal Fabrication Costs

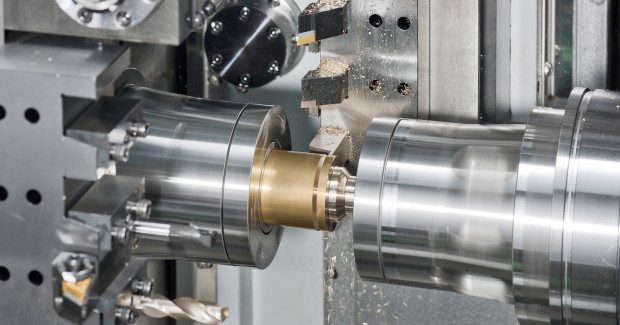

Costimator® V12.1 from MTI Systems can estimate machining, fabrication and part assembly processes so shops can quickly quantify the impact of changes to product design, materials, geographic locations, manufacturing processes, volume requirements and more.

Posted: July 12, 2014

MTI Systems, Inc. (West Springfield, MA) has announced the addition of 24 new cost models to their recent V12.1 update of Costimator®. This update benefits estimators with more speed, accuracy, and consistency as they use the company’s flagship cost estimating software product to estimate and quote manufactured parts.

The company offers estimating solutions to parts suppliers and OEMs who need to estimate machining, fabrication and part assembly. One method, of the many estimating solutions included in Costimator®, is configured using cost models. These models are custom easy-to-use formula based methods for estimating manufacturing processes.

They have inputs or drop down lists, as well as formulas that quickly and easily complete calculations for manufacturing time and/or cost. Additionally, using the embedded cost model editor; estimators can easily add or modify any of the 300 plus models currently shipped with the system — long after implementation. This provides estimators the flexibility to mimic estimates based on manufacturing processes in their shop or that of an outsourced supplier.

“In today’s competitive marketplace, it’s only natural that more cost models should be added to Costimator®,” explains Rene Laviolette, the MTI Systems vice president of product development. “Satisfying our customers growing needs and responding to emerging new technologies are key factors as to what we select for new features in Costimator® updates and upgrades.”

Some cost models included in the V12.1 update include:

- Holes – Back spot face, countersunk.

- OD (outside diameter) – face end, multi diameters, undercuts, threads, o-rings, and spline.

- ID (inside diameter) – multi diameters, undercuts, threads, spline, surface finish, flat surfaces.

- Specific processes – plasma part, cost-complete, knurling, step forming, and brake.

- Outside processing – finishing, heat treat, machining, plating, and freight.

- Modified models – broaching, grinding, welding, FCAW (flux core arc weld), and TIG (tungsten inert gas) weld.

Gardner Manufacturing Company, a sheet metal manufacturer based out of Wisconsin, finds that the additional new upgraded cost models enhance their software adding timesaving benefits, as well as increasing its consistency and accuracy.

“It’s such a great benefit to have a software vendor such as MTI Systems continue to add new features and manufacturing data,” reports Robert Marschke, estimating engineer at Gardner. “As they continue to increase its estimating power, we save even more time – which of course converts to cost-savings for our company and our customers.”

Costimator cost estimating and quoting software is designed for manufacturers of all sizes including single-man job shops, large contract manufacturers, precision machining and fabrication shops, as well as full-service OEMs. Manufacturers need to estimate time and calculate the cost for a wide variety of parts and projects.

They can choose from various “user selectable” cost estimating methods. With unique options such as drag and drop and comparing multiple estimates on the computer display screen simultaneously, estimators can quickly quantify the impact of changes to product design, materials, geographic locations, manufacturing processes, volume requirements and more.

MTI Systems provides cost estimating software and estimating services to manufacturers worldwide, serving both suppliers and OEMs. Since 1982, Costimator has been implemented at over 1,500 companies with over 12,000 trained users.

MTI Systems, Inc., 59 Interstate Drive, West Springfield, MA 01089, 413-733-1972, www.mtisystems.com.