Advanced Monitoring of Complex Machining Operations

The new generation Artis CTM V6 system from Marposs monitors the machine tool, tooling, coolant flow and related process operations to safeguard and enhance complex machining applications, such as gear hobbing, deep hole drilling and more.

Posted: August 10, 2014

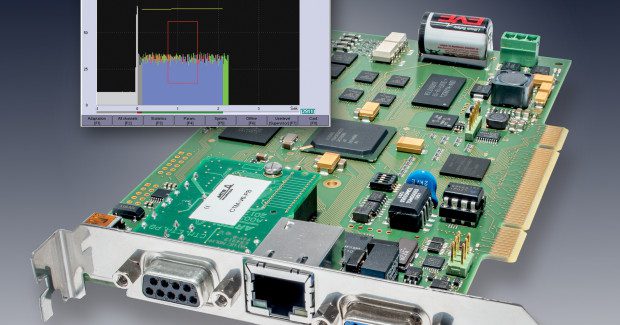

Marposs Corporation (Auburn Hills, MI) has announced the introduction at IMTS 2014, in Booth E-5519, of its new generation Artis CTM V6 tool, machine and process monitoring system that safeguards and optimizes complex production processes thanks to aligned in-process monitoring.

The flexible interface concept enables problem-free integration within many environments, from entry solutions with no fieldbus connections, to branched Ethernet architectures such as PROFINET, Ethernet/IP™ and Modbus.

Using the CTM system, evaluation and control are carried out with process-dependent strategies. Instead of searching for the smallest common denominator, CTM offers a range of strategies to optimally monitor the process.

Each individual parameter can be very finely adjusted and precisely adapted to the process. Process monitoring operates precisely and reliably from the very first cut. In the basic installation, the CTM system is interfaced with the machine control and accepts inputs from various measuring transducers.

Data capturing is accomplished using a sensor-less digital torque adaptor (DTA), wherein a selection of drive data is collected by the control for the evaluation of the torque of the spindle and the feed axis. Additional or alternative sensors are available for measuring strain and force, true power, torque, vibration and acceleration, acoustic emission, and standard power or voltage signals.

Optionally, the CTM V6 system can provide Adaptive Control for adjusting the feed speed to compensate for material deviations. This function protects both machine and tool under high load by reducing the feed force.

For gear hobbing applications, the CTM V6 system improves quality and extends the productive life of hobbing tools by utilizing wear-based method safeguards as opposed to traditional replacement at fixed regular interval methods.

Monitoring of coolant flow using the CTM V6 system is especially useful for processes with small tools such as deep-hole drilling. Tool related, automatic and process accompanying documentation provided by the CTM V6 system is based on precise data. Visualization software is a fundamental part of the CTM V6 tool and process monitoring system, enabling thorough evaluation of processes in a user-friendly manner.

Main benefits of the new CTM V6 system include comprehensive protection of tools and machines; process optimization; lower of unit costs by reducing the number of rejects; perfect adjustment even in the case of complex processes; and seamlessly documented component quality.

Marposs Corporation, 3300 Cross Creek Parkway, Auburn Hills, MI 48326, 248-370-0404, marposs@us.marposs.com, www.artis.de.