Fine Tune Machine Tool Servo Drives

The Auto-Tuning program from Fagor Automation fine tunes machine tool servo drives one axis at a time, all axes automatically, or even multi-machine tuning.

Posted: August 10, 2014

Fagor Automation (Elk Grove Village, IL) is introducing a new technology feature that automatically fine-tunes machine servo performance to create maximum efficiency and performance from the CNC machine tool. Developed as a tool that can be loaded directly on a Fagor 8065 or 8070 CNC or on a PC, this Auto-Tuning feature has the ability to carry out a fine Servo-Performance tuning one axis at a time, or all axes automatically.

The program allows for multi-machine tuning, thus utilizing an ICON directory for each machine for fast and easy machine selection. The Main Tuning Screen displays a Graphic section, Menu Bar, ICON bar, Axes Bar, Command Bar, Parameter Table, Monitoring area, Results area, Data information of all active commands and a Status Bar, thus providing a single page simple layout that allows quick and easy access to any data the User desires with a single click. From the Main menu, with the ICON keys, you can quickly jump to the Event Log, Configure Mode or Display Help mode or back to the Main Menu at any time.

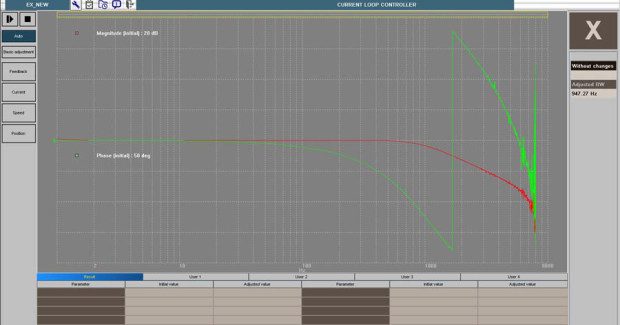

Even during the tuning process, the user can start, stop, pause or continue the tuning procedure via menu chosen keys. Within the Graphics mode, the Bode frequency response diagrams can be displayed that allow the user to interpret the dynamic behavior of the axes and make decisions for later readjustments of the axes control loops.

Within the Operating mode, the user takes measurements and develops a more detailed display of the various Diagrams. The user may activate up to four channels or modify the scale shown. From the Command Bar, the user may choose the Auto-tuning command that will execute the chosen tuning procedure. If desired, the user can choose to only adjust the feedback, the proportional gains, the offsets, just the servo gains or the velocity or position loop.

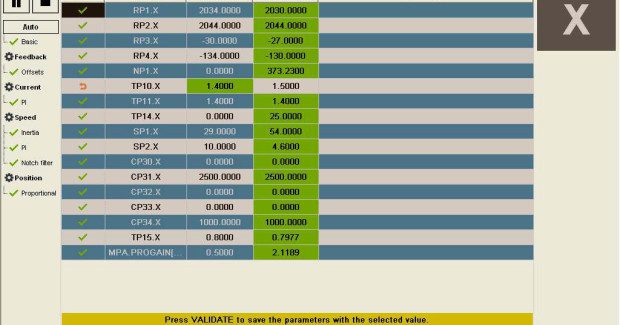

The “Result” label prompts a non-editable table that shows the parameter values the AutoTuning procedure results proposes to be changed for best performance. The Table shows the original value of the parameters and the proposed value after the Auto-Tuning procedure has completed. The user has full control of which parameters are actually changed to the proposed value and those that remain with the initial default values.

In addition, the Results create an information bar that displays the data regarding the cutoff frequency (BW), the gain margin (MG) or the phase margin (MF) of the Bode diagram before and after the Auto tuning, thus producing a helpful visual improvement chart for final decision making by the user.

After completion of the Auto-Tuning Process, the user can then save all changes made with the Validate command. The Fagor Auto-Tuning feature has shown dramatic improvements in not just Part-Finish, but also due to an optimized Servo Response that matches the dynamics of the machine tool size, weight and inertia, Cycle speeds have also shown improvements. Machine reliability and longevity will also be improved due to a Servo System that provides more fluid machine movements, hence reducing mechanical stress.

Fagor Automation, 2250 Estes Avenue, Elk Grove Village, IL 60007, 800-423-2467, www.fagorautomation.com.