IMTS 2014: Abrasive Machining, Sawing, Finishing

Here are solutions for applications requiring high tolerance and precision surface finish, including grinding technology, sawing and cutoff machines and a variety of finishing systems, such as lapping, balancing, honing and polishing machines. You’ll also find advancements in abrasive size, shape or composite materials, and nano-materials for improved surface finishes in more constrictive areas.

Posted: August 1, 2014

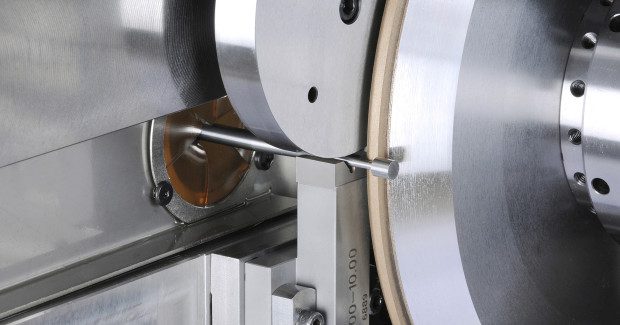

COMPACT VERTICAL CNC GRINDERS

In Booth N-7353, GPV-10 and GAV-10 Vertical CNC Grinders from Shigiya USA Ltd. (Schaumburg, IL), a world-class manufacturer of cylindrical grinders, feature compact footprints to accommodate a range of production line layouts. In fact, the main body of these machines is approximately 1 sq m, or about half the size of an existing Shigiya GAC-20 Grinder. Contributing to GPV-10 and GAV-10 accuracy is an original non-concentric hydrodynamic bearing for the wheel spindle. Mounted on the wheel side of the wheelhead, this bearing maintains low processing heat by optimizing the bearing clearance and the wedge angle. Infeed is performed by the table moving toward the wheel.

These vertical grinders are loaded with features that promote ease of use, including a wide machine opening that allows for flexible automation of loading/unloading and easy maintenance. What’s more, an electrical control panel hinged on the rear of the machines swings open wide to ensure enough working space for easy wheel change. The wheel changer of the GAV-10 enables for smooth wheel change, easier operation and reduced operator fatigue. Removal and attachment of the grinding wheel are performed by the vertical movement of the air cylinder. The arm can be manually moved back and forward with ease. The grinding wheel of the GPV-10 is not angled and does not require a wheel changer to be changed.

Both the GPV-10 and the GAV-10 feature a ø 100 mm swing over table, and 150 or 200 mm distance between centers. Wheel sizes are ø 305 mm OD x 25 mm W x 127 mm ID or ø 355 mm OD x 25 mm W x 127 mm ID.

http://youtu.be/xqM-tFidujE

A demonstration of the Shigiya grinding machines.

Shigiya also offers its versatile and precise GSU Series of Universal Grinders that feature a wheelhead NC swivel function which enables the operator to select from 9 different wheelhead installation patterns. Using the correct wheelhead installation pattern and specifications allow a variety of multi-grinding tasks to be performed and reduce the number of processes. For additional flexibility, two grinding wheels can be mounted onto two wheel spindles of the GSU, contrasted with conventional machines where two grinding wheels are mounted onto one spindle. The wheelhead is swiveled at high speeds by a direct drive system, and provides high positioning accuracy without backlash.

The GSU is designed with non-concentric hydrodynamic bearings that use hydrodynamics to secure the optimal wedge angle, and provide high precision rotation of the wheel. The bearings are ground with an exclusively developed grinder to ensure high rigidity and precise rotation. The GSU tailstock is mounted with a large diameter spindle to further ensure high precision heavy grinding. Heat expansion of the workpiece during grinding is offset by a helical compression spring. To avoid thermal displacement in the machine caused by a rise in the lubrication oil’s temperature, wheel spindle lubrication oil is stored in an isolated tank.

Shigiya offers an optional closed type hydrostatic slide wheelhead feed and a work spindle rotation direct drive to enable an operator to actually perform eccentric OD and non-concentric OD grinding (polygonal grinding) using the C-X axis control. Two models of the GSU Series are available. The GSU-30B features a ø 300 mm swing over table, and 500 mm, 750 mm, 1,000 mm or 1,500 mm distance between centers. The GSU-40B features a ø 410 mm swing over table, and 470 mm, 720 mm, 970 mm or 1,470 mm distance between centers. A model with distance between centers of up to two meters is available to allow for the grinding of long parts such as aircraft landing gear. Wheel sizes for both GSU models are ø 510 mm OD x 50 mm W x 127 mm ID. www.shigiya.com

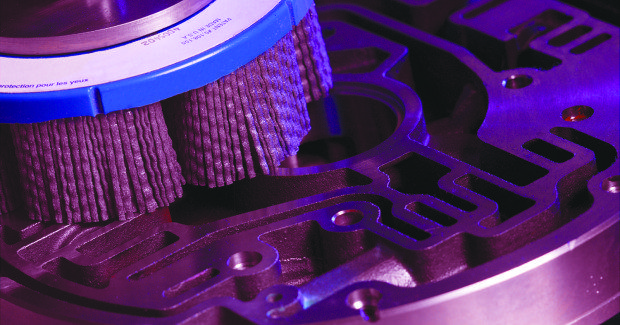

DIAMOND COMPOSITE HUB WHEEL BRUSHES

In Booth N-7163, Brush Research Manufacturing Co., Inc. (Los Angeles, CA) is pleased to announce an expansion in their abrasive nylon product line to include diamond impregnated composite hub wheel brushes. The introduction of the new diamond filament wheels extends the range of their finishing and deburring tools to now finish harder materials like glass, ceramic, carbide and hardened tool steels.

These new brushes are composite hub construction which yields a much denser and more uniform fill pattern putting more cutting points at the point of attack. The new black diamond filled composite wheel brushes come in three diameters: 100 mm, 150 mm and 200 mm. The 150 mm and 200 mm diameters come in either 10 mm or 15 mm face thickness to accommodate a variety of flute relief requirements. The 100 mm diameter brush is manufactured in a 5 mm face width to allow finishing smaller sizes.

The black diamond filament comes standard in 600 grit which has proven to have the perfect combination of cutting power and ultra smooth final finish. Other grits are available on special order. These wheels are extremely long lasting and priced well below other diamond wheels on the market. www.brushresearch.com

ADVANCED GRINDING TECHNOLOGIES

In Booth N-6800, United Grinding North America, Inc. (Miamisburg, OH) will showcase 19 grinding machines, including two historic machines – the largest number of products the company has ever had at the show. Booth highlights will include the global introduction of a Studer ID cylindrical grinder, the North American debut of a Mägerle surface and profile grinder and the 20th anniversary of Walter’s best-selling CNC tool and cutter grinder. Applications experts will also be available to help attendees determine the right grinding solution for their manufacturing needs.

With its new ID cylindrical grinding machine series, the Studer brand is entering a new market segment of long workpiece production, such as spindle housings and rotor shafts. One of the machines in this series that will be on display can process short work pieces via an overhung grinding spindle as well as grind parts up to 51.2 in (1,300 mm) long with an additional steady rest. The maximum internal and external grinding length for this machine is 9.8 in (250 mm) and 5.9 in (150 mm), respectively. With linear motors and a StuderGuide precision guideway system, the series is equipped with the latest drive technology in order to meet today’s customer demands.

A demonstration of a Mägerle MFP 100 5/6-Axes Grinding Center with Toolchanger.

Its original version was introduced at IMTS 20 years ago. Now the latest Walter Helitronic Power CNC tool grinding machine brings precision, productivity and flexibility to the production and re-sharpening of rotationally symmetrical tools and parts with complex geometries. In honor of its two decades of success, which includes more than 3,800 units sold worldwide, the machine on display will feature a custom-painted design.

During IMTS, United Grinding North America, through its comprehensive grinding machine selection on display, will be prepared to present manufacturing solutions as they specifically pertain to productivity enhancing factory automation, optimizing total cost of ownership, minimizing production costs per part, and providing total turnkey installations. Additionally, the company encourages attendees to bring their part drawings to its booth so applications engineers can discuss the most appropriate grinding solution for their needs, including complementary workholding, fixturing, tooling, robotics and machine monitoring.

Customer care will also be an important focus inside the booth. To keep up with its unprecedented growth over the past couple of years, the company continues to invest in customer-centric business processes to ensure its products and services remain aligned with customer requirements. In fact, the company recently implemented an internal cross-function initiative, known as PuLs®, to help make its customers more successful than ever. This initiative focuses on applying best practices in every aspect of the company’s business, from sales to applications support to training to preventive maintenance. And, as part of the PuLs initiative, the company regularly sends out surveys to effectively gauge customer satisfaction levels using the Net Promoter Score® measuring method.

United Grinding North America is the subsidiary for the North American market, with two production plants of 16,732 sq ft space in Miamisburg and 16,732 sq ft in Fredericksburg, VA, and over 155 employees around North America. Apart from its production plants in the U.S., the company runs an additional sales and service office in Queretaro, Mexico, and occupies a leading position in the North American grinding machine tool market by offering innovative products in the technology areas of surface and profile grinding, cylindrical grinding and tool grinding. www.grinding.com

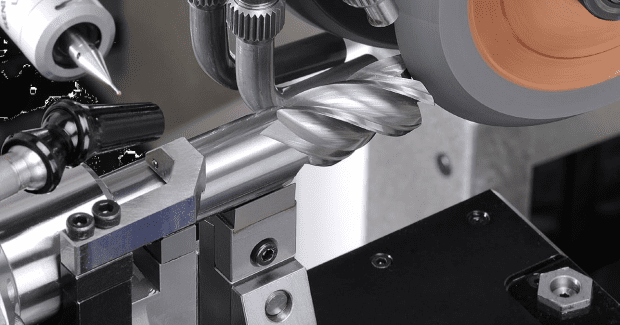

UNIVERSAL 6-AXIS PRODUCTION TOOL GRINDER

In Booth N-7200, Rollomatic Inc. (Mundelein, IL), a leading machine tool manufacturer based in Le Landeron, Switzerland, will announce a 6-axis CNC tool grinder for production grinding of a large variety of diverse cutting tools that enables shops to achieve sustained competitive advantage. With new software developments, larger hp and higher rigidity of the machine base, in-field use of the modified GrindSmart 628XW® with SmartChanger® has demonstrated that this machine tool is ideal for increased productivity on an extended range of different high-performance cutting tools, including:

- Carbide endmills up to 20 mm (3/4 in) = 11 min

- Carbide drills up to 12 mm (1/2 in) = 8 min

- Razor-sharp cutting edge with polish wheel

- Sticking of wheel with max. spindle load of 30 percent

- Step drills

- Form tools/drills

- Stepped endmills

- Miniature tools

- Porting tools

- Thread endmills

- Indexable inserts

- Reamers

- Enlarged coolant supply 30 gal/min