IMTS 2014: Abrasive Machining, Sawing, Finishing

Here are solutions for applications requiring high tolerance and precision surface finish, including grinding technology, sawing and cutoff machines and a variety of finishing systems, such as lapping, balancing, honing and polishing machines. You’ll also find advancements in abrasive size, shape or composite materials, and nano-materials for improved surface finishes in more constrictive areas.

Posted: August 1, 2014

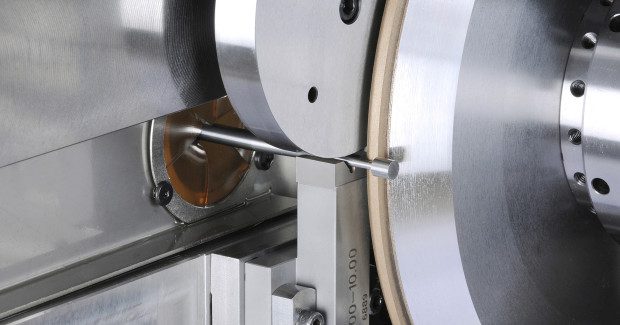

Ideal for job shops and repair facilities, the SV-20 is equipped with a variable-speed 15-550 rpm, 4.1 kW (5.5 hp) spindle motor, powerful enough to drive two-stage, metal-bond, diamond abrasives for short cycle times with high accuracy and minimal labor. A linear stroking system keeps the honing tool concentric with the bore throughout the full stroke length to produce a consistent diameter from top to bottom of the bore. The work envelope of 915 mm x 1015 mm (36 in x 40 in), front-loading design, and weight capacity up to 680 kg (1500 lb) combine for versatility in processing a wide range of large parts. The SV-20 can be used to hone bores with inside diameters from 19 mm to 200 mm (0.75 in to 8.00 in).

The machine is compatible with all of Sunnen’s past and current tooling for CK/CV/SV-series machines, including diamond abrasive hone heads and brushes, GHSS single-stage hone heads with CBN or diamond abrasives and brushes, and GHTS hone heads for two-stage honing with CBN or diamond abrasives. The SV-20 is available with a 400V/50Hz/3Ph or 460V/60Hz/3Ph electrical system. Options include a T-slot base, manual rollover cradle for engine blocks, and sump pump to allow connection to an external coolant supply.

Sunnen’s PG Bore Gages take an intuitive approach to hole gaging with a mechanical design and speedometer-type scale for quick visual confirmation of ID (inside diameter) by a busy machine operator. The gage combines lab-precise accuracy (±0.000025 in / 0.0006 mm) with a shop-hardened design that is compact, portable and mountable on machining stations. The speedometer-type scale provides readouts down to 0.000050 in (.001 mm) for 100 percent inspection of machining operations or fast sampling of large vendor lots. Various models are available for gaging IDs from 0.090 in to 4.310 in. Metric models cover IDs from 2.0 mm to 109.47 mm.

The PG Bore Gage removes complexity, skill and “feel” from the measurement process, allowing machine operators to precisely confirm part size with an intuitive analog scale. The unique design of these gages is not affected by temperature, moisture, air pressure, or vibration, and they need no electrical or air connections, making them immune to fluctuations in line voltage or air pressure. A calibration ring traceable to NIST and international standards comes with the gage and features nominal size at 68 deg F marked on the face. Calibration checks with the ring ensure that gage-setting capability retains accuracy within original limits of ±0.000020 in. www.sunnen.com

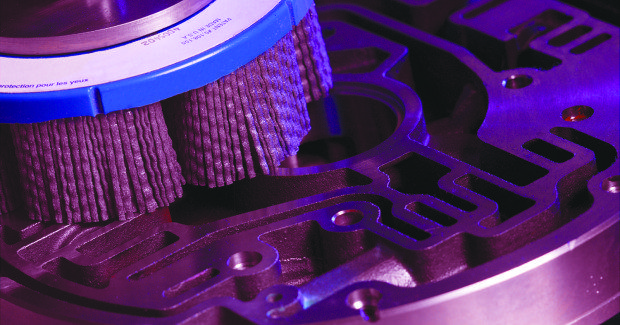

ADVANCED DEBURRING TOOLS

In Booth N-6748, Weiler Corporation (Cresco, PA) displays a complete offering of Burr-Rx® deburring tools, including power tube brushes, small-diameter wheels, Bore-Rx internal deburring tools, and large-diameter wheel, disc, miniature disc and banded end brushes – all manufactured with an advanced ceramic-grain abrasive filament. Weiler offers the most comprehensive line of high aggression, compliant brushing tools that address practically any automated deburring need.

The black nylon filaments of our Burr-Rx brushes are co-extruded with an engineered ceramic abrasive grain, providing cut rates up to 400 percent faster than standard silicon carbide or aluminum oxide filaments. The extreme aggression of Burr-Rx brushes reduces cycle times by allowing the use of high feed rates and short dwell times, resulting in increased throughput and lower deburring costs. Burr-Rx brushes can also remove burrs that are impossible to remove with conventional nylon abrasive filament brushes. www.weilerabrasives.com

MAGNETIC TECHNOLOGY FOR MATERIAL MOVEMENT

In Booth N-7358, Bunting® Magnetics Co. (Newton, KS), a producer of precision magnetic products for the worldwide printing, plastics, food, recycling, automobile, and electronics industries, will exhibit a broad range of magnetic products, including the Bunting Magslide and Low Profile Conveyors. Bunting conveyors are fitted with powerful magnets which reliably move ferrous parts and material in the manufacturing environment.

A demonstration of the Bunting® MagSlide® Magnetic Slide Chip and Parts Conveyor.

For attendees seeking to learn more about magnetic technology, Bunting personnel will be available to explain the differences and advantages of Neodymium, Samarium Cobalt, Alnico, Ceramic, and other magnets in product design.

For more than 50 years, Bunting Magnetics has developed and manufactured precision magnetic products for the worldwide printing, automobile, plastics, food, electronics and recycling industries with a broad range of magnetic materials and components, magnetic separation systems, material handling equipment, magnetic printing cylinders, metal detection equipment, bonded magnetics, and assemblies. Bunting manufacturing facilities are located in Newton; suburban Chicago, IL; DuBois, PA; and Berkhamsted, England. www.buntingmagnetics.com

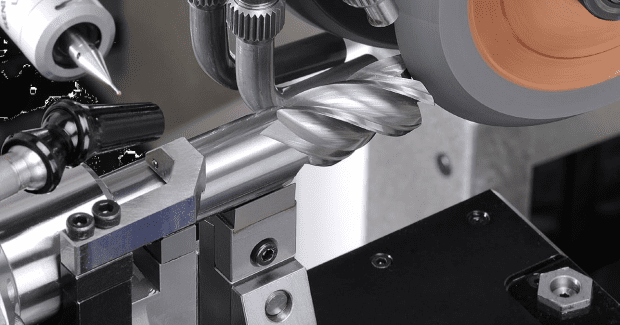

REPLACE THREE BANDSAWS WITH ONE CIRCULAR SAW

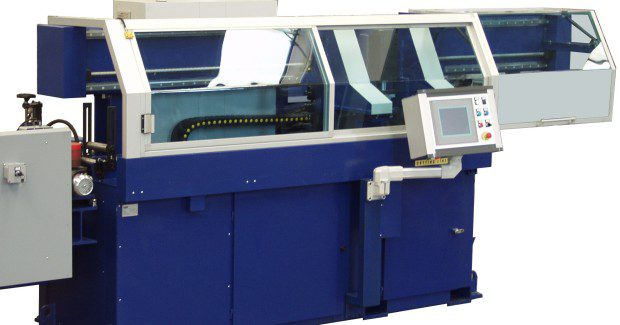

In Booth N-7429, Pat Mooney, Inc. (Addison, IL), North America’s sales and service center for the world’s most innovative and durable metal sawing systems, will demonstrate the OMP KR3 Fully Automatic Circular Miter Saw that is designed for production sawing applications requiring straight and miter cuts on bars, tubes and structural work pieces.

For high-speed cutting and extended saw blade life, several design features are built into the system. The OMP KR3 saw head is hydraulically driven and controlled via a servo feed system for precise control of the feed rate. The gear box is equipped with a hydraulic brake to ensure that all backlash is removed from the system, resulting in longer blade life and allowing for use of carbide or HSS saw blades. “OMP ZONE CUT Technology adjusts the feed rate during the cut when sawing tubes (round or square),” explained Pat Thornton, Jr. “When sawing tubes, there are critical zones that can reduce blade life — the entry and exit points of the tube when the saw is cutting wider, thicker sections of material. In addition, there is an ‘express zone’ where the feed rate can be increased without wearing the saw blade because the blade is cutting through thinner sections of material. In the express zones, ZONE CUT will automatically increase the feed rate, and in the critical zones, it will automatically decrease the feed rate. This specifically results in faster cut times and extended saw blade life.”

An integrated loading system is available that automatically loads round and square materials into the saw. This system can accept bundles weighing up to 8,800 lb and will load material until the saw program is complete or the saw is out of material. The KR3 can also be equipped with unloading systems configured for specific cut lengths and customer requirements.

Thornton added, “Visitors will be interested to learn how easy the system is to operate and program with the Siemens touchscreen control system. We are also eager to demonstrate the design advantages in the material feed, unloading, and clamping systems of the KR3.” Attendees should stop by for demonstrations of additional saw systems, including a Nishijimax® CNC Carbide saw, PMI upcut and high precision cutoff saws, Danobat fully automatic production band saws, and FMB precision band saws.

Dedicated to serving the U.S and North American fabricating, metalworking, tube and pipe, and industrial markets through a network of knowledgeable distribution partners, Pat Mooney is the exclusive sales and service center for the world’s most innovative and premium quality saw manufacturers, including Nishijimax®, OMP, PMI, Danobat, and FMB. Kanefusa high speed saw blades, spare parts and sharpening services are also available through Pat Mooney. www.patmooneysaws.com