IMTS 2014: Metal Cutting

Come explore the very foundation of the machine tool industry, a group that represented more than $500 billion in worldwide consumption in 2009. This pavilion is where you’ll find the latest innovations in metal cutting equipment, machining centers, turning centers, drilling, boring, milling, and more.

Posted: August 8, 2014

On the self-contained automation side will be demonstrations of the highly efficient performance and productivity of the full five-axis Mikron HPM 800U through its integrated pallet changer and tool magazine options that accommodate up to 210 tools. Designed for the production of tools, molds and high-value parts, the HPM 800U features a sturdy and compact design with a large working space. Maximum X-Y traverse paths are 31.5 in each, with a Z-axis that provides 27.6 in clearance between the table surface and spindle nose. Workpieces of up to 31.5 in diameter and 23.6 in height can be machined on five sides.

While typically paired with sinker EDMs, a System 3R WPT1 robot, together with the CUT 2000 S (Swiss high precision) model, will comprise a completely automated wire EDM cell in the booth. Available in four configurations, the robot is also compatible with milling and laser equipment. The system gives end users a full range of automation options suited to their applications and provides the capability to address parts and tooling for two machines at once. The robots are affordable, flexible and sleekly designed and accommodate a wide range of part sizes and weights.

Enhancing automated unattended operation and boosting productivity, the CUT 2000 S incorporates the new Threading-Expert module for dependable, fully automatic threading under difficult conditions. It also features the second-generation Integrated Vision Unit (IVU Advance) for in-process inspection and the well-known Agie Charmilles Automatic Wire Changer. The machine raises the bar in the speed arena. It is one of, if not the industry’s fastest wire EDM solution on the market thanks to its Intelligent Power Generator (IPG) technology with Direct Power Supply (DPS) module. This machine has been proven to reduce machining time by 30 percent and produce high-quality surface finishes of Ra 0.08 μm.

A demonstration of the CUT 2000 S Threading-Expert module.

The Form 20 and iRTC combination forms an ideal solution for manufacturers looking to maximize their die-sinking EDM operations while minimizing their environmental footprint. The highly efficient sinker machine provides exceptional performance, yet consumes less power via what the company considers to be one of the most advanced sinker EDM generators currently available. The proprietary IPG requires just 3.7 kW/h at full power. The Form 20’s IPG includes built-in quality boosting, cost saving intelligence. With every machine pulse, the 70 amp generator continuously optimizes the EDM process and dramatically reduces electrode wear as well as provides extremely uniform surface finishes. The machine’s iQ Technology generates surface finishes of Ra 0.1 micron and radii down to 0.0007 in.

An overview of the Form 20 sinker EDM

In addition to its special power generator, the Form 20 features the recently developed Agie Charmilles AC Form HMI. Revolutionary in its simplicity, this CNC provides the most user-friendly, easiest to learn and most flexible control developed for a die sinking EDM. The newly unveiled Transformer modular automation solution from System 3R will also be featured in the booth. This revolutionary product can easily be integrated with a single machine, but can also be seamlessly expanded to include up to twelve machines within a cell. The system accommodates a wide range of machining technologies and simplifies unifying diverse machines into a highly efficient production cell. www.gfms.com/us

5-AXIS MACHINING AND AUTOMATION

In Booth S-9490, Grob Systems, Inc. (Bluffton, OH) displays G-Series universal machining centers that are based on a horizontal machining center platform popular with automotive OEMs. These universal machines are designed for manufacturers in medical, aerospace, die/mold and other industries.

Both the G-350 and G-550T feature the Grob-designed and built table with 225 deg of rotation in the A-axis, and continuous 360 deg in B-axis. It is possible to completely invert the table for upside-down machining while chips simply free-fall away from the part. Grob Systems, winner of 2013 GM Supplier of the Year Award, is a family-owned company that builds machines in the U.S. and Germany. All replacement parts and factory service are available from the 300,000 sq ft facility in Bluffton. www.grobgroup.com

http://youtu.be/IouHzfKiCzc

A demonstration of a Grob G350 machining an Aluminum Intake Manifold at Merrifield Machinery Solutions.

LARGE THROUGH-BORE TURNING CENTER

Big parts are big business. And today’s shops need large-capacity machines to handle the big jobs commonly found in such industries as oil and gas exploration, alternative energy, mining, and aerospace. In Booth S-8119, the ST-55 from Haas Automation, Inc. (Oxnard, CA) is a heavy-duty, large-bore turning center that is extremely rigid, highly accurate, and very thermally stable. The machine’s twin-chuck capability, high-torque spindle, and 12.5 in (318 mm) diameter through-bore make it ideal for machining heavy pipes and fittings, large couplers, and long rollers. It has a maximum cutting capacity of 25.5 in x 80 in (648 mm x 2032 mm), with swings of 34.5 in (876 mm) over the front apron and 25.5 in (648 mm) over the cross slide. A servo-driven tailstock (MT5 taper) is standard, and a steady rest provision is available for additional support of long shafts.

A 55 hp (41 kW) vector dual-drive unit powers the ST-55 spindle through a Haas-built two-speed gearbox to provide 2100 ft-lb (2847 Nm) of torque in low gear. High gear provides a maximum spindle speed of 1,000 rpm. Both front and rear, A1-20 spindle noses accept a variety of aftermarket large-diameter manual and pneumatic chucks. The ST-55 comes equipped with a massive hydraulically clamped 12 station bolt-on style tool turret that accepts 7.25 in (184 mm) split boring bar holders, as well as standard BOT toolholders. An optional hybrid BOT/VDI turret is available. Standard equipment includes rigid tapping, a color remote jog handle, a 15″ color LCD monitor, and built-in USB connectivity. Available high-productivity options include a belt-type chip conveyor, high-torque live tooling with C-axis, high-pressure coolant systems, and much more.

The rear chuck area is also fully enclosed during machining, but a wide sliding door and swinging end panel provide complete access from the front and top, simplifying chuck installation and adjustment, and making it easy to load pipe using an overhead crane. Unlike some competing machines, it’s not necessary to remove sheet metal panels or modify the enclosure to handle drill pipe. Built in the U.S. by Haas, the new ST-55 is backed by the worldwide network of Haas Factory Outlets, the most extensive system of support and service in the industry.

Five-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. Machining those parts quickly further increases throughput and improves the bottom line. The UMC-750SS universal machining center from Haas is a high-speed solution for quickly machining 5-sided (3+2) and simultaneous 5-axis parts. The UMC-750SS is a 5-axis, 40 taper universal machining center with 30 in x 20 in x 20 in travels, 1200 ipm rapids, and an integrated high-speed, dual-axis trunnion table. The machine is equipped with a 15,000 rpm inline direct-drive spindle, a high-speed 40+1 tool side-mount tool changer, and Haas Automation’s powerful high-speed machining software.

To simplify job set up, the UMC-750SS features Dynamic Work Offsets and Tool Center Point Control, and comes standard with Haas Automation’s Wireless Intuitive Probing System. The machine’s 15,000 rpm inline direct-drive spindle is powered by a 30 hp vector drive system that yields 90 ft-lb of cutting torque. The Haas inline system couples the spindle directly to the motor to reduce heat, increase power transmission, and provide excellent surface finishes. A wide selection of high-productivity options is available for the UMC-750SS, as well, including a belt-type chip conveyor, high-pressure through-spindle coolant systems, expanded program memory, and much more. If you’re searching for a high-speed 5-axis solution to reduce setups, increase accuracy, and boost throughput, look no further. The UMC-750SS from Haas is the answer. www.HaasCNC.com

NEW TURNING, MILLING AND GRINDING MACHINES

In Booths S-8738 and N-6936, Hardinge Inc. (Elmira, NY) will showcase advanced metal‐cutting solutions, including the debut of the ultimate bar machine, the all newConquest H51 SUPER-PRECISION® turning center that represents the latest in technology, precision and, most importantly, capability. This machine is available in both high performance and SUPER-PRECISION® models. The Conquest H51 SP machine sets the standard for SUPER-PRECISION® turning with outstanding performances specifications such as:

- Part Roundness – Main Spindle .000020 in (.5μm)

- Continuous Machining Accuracy deviation on diameter within .0002 in (5μm)

- Part Finish – Main Spindle .000008 in (.2μm)

High performance and SUPER‐PRECISION® productivity packages are available for choosing from features that include Live Tooling with C‐Axis, Sub-Spindle and Y‐axis. The Conquest H51 is offered with either a Fanuc 0i-D or Mitsubishi 720 control, each packed with a host of standard features. A company spokesperson noted, “This new product solidifies our leadership as the only machine tool builder to offer a collet ready spindle in a high performance and SUPER-PRECISION® turning. This machine also shows our commitment to producing the highest quality products for the global marketplace. We are proud to add Conquest H51 turning center to our product line.”

The all new Bridgeport Conquest V1000Vertical Machining Center is manufactured to the highest industry standards and comes packed with features to meet and exceed the requirements of the demanding metal-cutting market. This machine provides very fast rapid traverse of 1,693 ipm on X- and Y-axes and 1,417 ipm on the Z- axis and a highly sophisticated yet user-friendly Mitsubishi M70M control with NAVI MILL Programming and 10.4 in LCD.

Also on display will be Special Application Workholding that is manufactured to rigid specifications, including material, heat treat and machined accuracy. Visitors will see precision-engineered Hardinge FlexC™ Collet Systems that mount to A2-5, A2-6 and A2-8 and select flat-back spindle noses. Pull-back thru-hole, pull-back dead-length and push-to-close dead-length styles are available for single and dual-spindle CNC lathes. Purchase one spindle mount and interchange vulcanized collet heads from job to job. These collet heads are fully interchangeable with competitor’s models.

Hardinge Swiss-type Colletsare ground to precise size and TIR to meet precision machining requirements with a standard accuracy that rivals the industry. These collets are manufactured to Swiss quality in the U.S. for all brands of Swiss-style machines and cam-operated lathes. Round Swiss Guide Bushings are carbide-lined to keep the stock clean and unmarked. The company manufactures bar feed collets for FMB, IMECA, LNS and Robobar bar feeders, but collets are available for other brands on request. A complete line of tool holders, tap holders, tool holder collets, tap collets and bushings is offered that can be used on Swiss-type lathes. You’ll find reliable and economical solutions for back-end, sub-spindle and end-working slides. www.hardinge.com

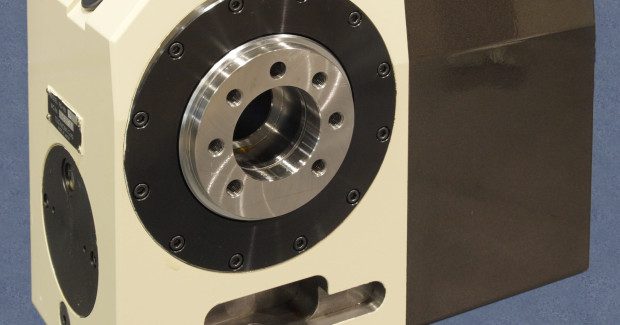

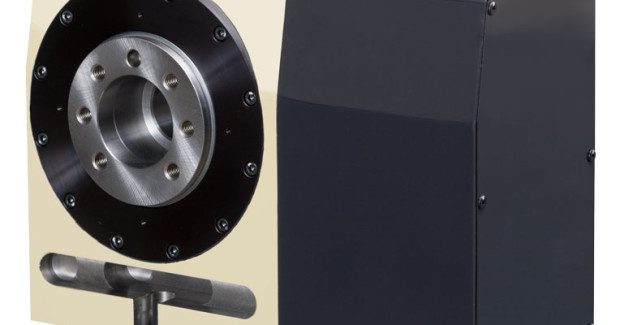

BIG BORE TURNING CENTERS FOR OIL FIELD PARTS

In Booth S-8129, Hwacheon Machinery America, Inc. (Vernon Hills, IL) will show a large Big Bore turning center designed for machining large oil field components. Based on its successful Hi-Tech 550, -700, and -850 horizontal turning centers, this machine offers best-in-class spindle torque, permitting productive cutting in tough material up to 36 in diameter and more than 216 in long.

The new Hi-TECH BB & BB+ turning centers feature through-spindle holes from 7.08 in to 14.57 in diameter for large pipes. Maximum cutting diameter on the Hi-Tech 850BB is over 36 in – best in its class of machines. Large air chucks can be fitted at the front and back of the spindle. Specifically, the range is HT-550BB with a 7.08 in through-spindle hole; HT-700BB offers 7.08 in BB+ 11.61 in; and HT850 has 11.61 in with BB+ at 14.57 in. Spindle noses ASA A2-15 to A2-20. Long bed versions of the centers are available from 84 in to 216 in.

The 4-speed automatic transmission system allows low-speed, high-torque turning as well as high-speed machining. Ultra-precision recuperative cylindrical roller bearings and the multiple thrust angular bearing have been incorporated to enable hard turning of tough alloys. The spindle may be geared down for extra torque to process a wide range of materials. All machines feature Hwacheon’s heavily ribbed torque tube design.

All BB turning centers are built with integrated bed frames of fine grain meehanite castings to minimize heat distortion. Plus, all guide ways are designed as solid box guide ways to maintain rigidity and precision even during prolonged, heavy operations. In addition, Hwacheon’s advanced thermal displacement control prevents deterioration machining tolerances due to thermal displacement. A jet of lubrication is constantly applied to the spindle bearing for lubrication and cooling, prolonging machine life and the machining precision.

These turning centers can handle multi-tasking machining with a Y axis head with stroke of 9 in and rapid positioning speed of 10 m/min. Heavy-duty bearings in the turning center’s tailstock assure a high degree of precision even after prolonged heavy-duty turning on a large, heavy workpieces. Machines also feature a 20,000 kg clamping force. Quill diameters range from 120 mm to 160 mm housed in a rugged built-in quill structure. The large steady rest capacity is 20 in. An air chuck is optional.

Each turning center is controlled by the Fanuc 0i control with Manual Guide i, a dialog-based programming system, allowing even a beginner to write an advanced program by following simple dialogs and menus. The data can easily be used to present a 3D model of the work and process, providing the operator with the preview of the actual outcome.

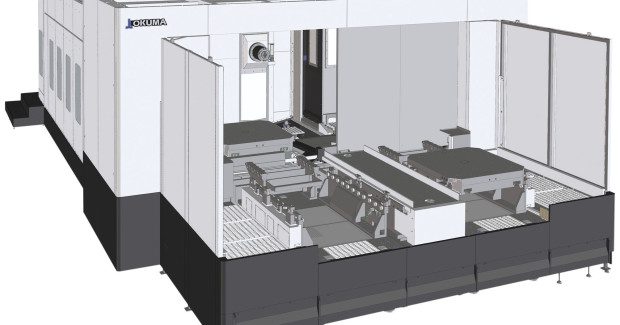

Also on display will be high-precision machining centers for die-mold applications. Hwacheon’s Sirius range of 3-axis vertical machining centers feature 20,000 rpm high-speed spindles for the UM and UL+ models and a 12,000 rpm spindle for the UX model. A number of useful options make mold-die machining more efficient with Sirius machines. Equipped with integral motor spindles with jacket cooling and oil-jet cooled bearings and rigid roller linear guide ways, the machines deliver stable performance over long cycles. According to the company, the Sirius range of high speed die and mold machining centers provide the industry high capability, extreme precision at an attractive price.

The bilateral gate structure in the Sirius-UM effectively distributes the vibration, weight, and heat throughout the entire frame. Finite element analysis methods help to minimize the frame distortion which may be caused by machining conditions or environment. The distance between the spindle and the body is designed short, so the machine stays stable after a prolonged operation.

The spindle is integrated with the motor to limit vibration, noise, and power loss at high speed rotation. The cooled jets of oil are injected directly onto the spindle bearing for effective cooling, and the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat. To achieve greater precision, standard Hwacheon software (HSDC) monitors the spindle for possible thermal displacement and makes necessary adjustment in real time.