Hot Rolling Zirconium Pushes Possibilities

British engineering company Charles Thompson Ltd breaks ground with a scarce source possibly never seen before – a heat exchanger component rolled from an unusually thick (40 mm) flat plate.

Posted: August 5, 2014

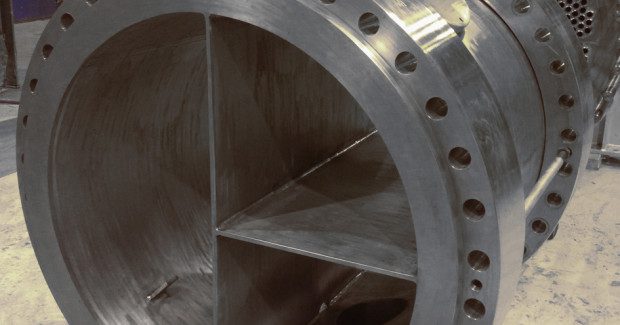

Charles Thompson Ltd (CTL; South Yorkshire, UK) has successfully produced a Zirconium bundle and header for a TEMA AKU type heat exchanger, from an impressive 40 mm thick flat plate. The parts were built to meet a client’s particular requirements; while clad Zirconium would have made production cheaper it would have demanded extensive testing within a specially built facility.

Instead, the company hot rolled the £70,000 Grade 702 Zirconium plate under strict procedures, controls and other special requirements to meet the client’s brief.

CTL’s technical director Peter Coe said: “We worked closely with the experienced supply chain to make sure we knew exactly what the manufacture of this cylinder would entail. They told us they hadn’t worked with a company that was rolling Zirconium to this thickness before, so we feel like we’ve achieved something special. The challenge was the rolling of the Zirconium at this thickness, taking into account the procedures, control and additional requirements like cleanliness, surface finish and uniform heat specifications.”

Coe continued, “Zirconium, especially of this form, doesn’t like being worked and the risks of cracking are extremely high. Of course, the part would be useless with one crack, and the smallest scratch or indent could have been disastrous.”

CTL engineers heat treated the Zirconium and pre-bent the ends to form the cylinder. These were machined and the plate was heat treated again, before final rolling and welding. Its completed dimensions were 40 mm thick by 910 mm ID by 1,200 mm long.

The components, which were required for use in the chemical industry, have been shipped to their new home. Meanwhile, CTL has received its official ISO 3834 certification for welding and fabrication.

Charles Thompson Ltd., South Yorkshire S64 5TD, United Kingdom, +44 (0)1709 584 011, Fax: +44 (0)1709 587 187, Email: info@charles-thompson.co.uk, www.charles-thompson.co.uk.