Clever Turret Press Tooling Produces More Parts In Less Time

Tooling changeover is a priority for this sheet metal job shop, which achieves quick setups, extra durability and increased uptime by using advanced tooling that makes its turret presses “operate like new.”

Posted: September 6, 2014

Supplier relationships are extremely important to business success. For SFI, Inc. (Orlando, FL), one reason its fabricating operations have excelled is because of its strong relationship with Mate Precision Tooling (Anoka, MN). SFI is an award-winning, comprehensive value-added precision sheet metal fabricator of a broad range of components and assemblies for the military, telecommunications, medical and food service industries. The company offers product design and engineering services, punching and fabricating, painting, silk screening, rubber stamping, welding, QC inspection and fully finished components.

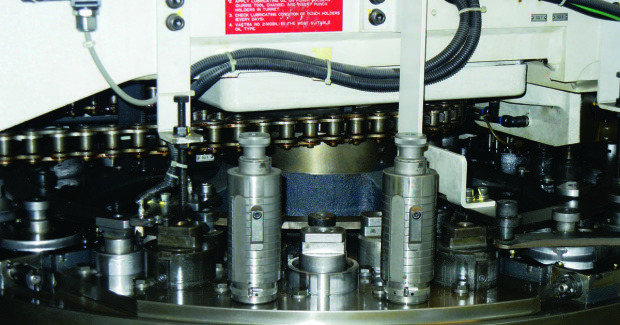

For punching operations the shop uses a Murata Wiedemann Motorum 2048-LT-CNC with four auto-index stations and 44 tool stations, and a Murata Wiedemann Motorum 2044-CNC punch press with four auto-index stations and 30 tool stations. Both presses are tooled with Mate Marathon Plus™ tooling.

Bud Sano, the president of SFI, has attributed increased uptime and fast tooling changeover to the shop’s long term relationship with Mate. “We started our company in 1978 and began with Marathon® tooling for our first press, a Wiedemann 2040,” recalls Sano. “We began building a tooling knowledge base with them, listening to their recommendations on how to best use the tooling for a particular job. As projects became more diverse and challenging, they helped us choose the right tooling to integrate into our processes.”

Take a look at how SFI uses Marathon Plus tooling in its fabrication operations.

Fabricating more parts in less time is extremely important to SFI, which has a high incidence of producing parts in small volumes of one to five. “We started off building many prototypes and it’s still a mainstay for us,” says Sano. “A long run for us would be about 5,000 parts a week. And we continue to produce many prototypes because they are important to our customers and they give us an edge in getting the longer run work.”

With such a wide range of projects and quantity requirements, the right tooling and tooling changeover is a priority. “We want anything that can help us cut time off our processes for our equipment,” notes Sano. “Punching is key to our operations, and it’s the tooling that lets our punch presses perform like new.”

Mate works with SFI as a Beta test site for trying out and experimenting with new tooling. One particular tool Sano recalls worked so well for the shop that they didn’t want to give it up after they tested it. They tried to persuade Vidal Rodriquez, the Mate sales engineer, to keep the tooling once the testing was completed. Those tools were early versions of the Marathon Plus™ tooling system, an enhanced version of Marathon® tooling that has all of the original benefits plus a unique way to adjust the punch length.

Instead of taking the tooling apart to change the punch length – which can take ten minutes or more – Marathon Plus tooling allows the operator to click and turn the outside barrel of the punch holder, thereby adjusting the length. This eliminates the need for disassembling the tool. Critical to precise punching, the external length adjustment feature provides highly precise tool length setting in 0.005 in increments. This design also eliminates the need for shims or adjusting tools, further minimizing punch press downtime.

Marathon Plus also features fully guided, long lasting M-2 high-speed steel punches for excellent edge quality and spring-loaded strippers for holding sheets flat and hole accuracy. Full length guiding from the shank, shoulder and punch tip provides perfect tool alignment and stability. Combining premium steel with a fully guided system allows users to attain a lower cost per hole when compared to other tooling systems. In fact, shops frequently report producing over one million hits before needing to sharpen. Also, punch holders are fully hardened and ground for maximum precision and long life.

Another key feature is the self-releasing “pop-up” stripper that eliminates tools during punch change out. Simply twist the retainer to release the stripper; there is no need to use a wrench to lock the plate. The hardened steel strippers ensure long life, while Slug® Free dies eliminate slug pulling for improved piece part quality and increased tool life. Other Marathon Plus features include multiple angle settings, an internal lubrication system, single draw bolt lock for positive punch retention, and minute corner radii to reduce chipping and extend tool life. Many of these tool design features are the result of input from fabricators like SFI.

“Testing new tool features like those with Marathon Plus provides great feedback for us in this shop,” states Rodriquez. “We can evaluate tolerances, premature wear, ease of use, downtime reduction, quality of holes, and nibbling edge blending from hit to hit. Once that information is collected, we use the data to determine if tool design refinements or improvements are needed or desired.”

With the extended hit rates that Marathon Plus delivers, press longevity is extended, according to Sano. “We typically get well over a million hits on a given tool before sharpening or replacement is needed,” he says. “We can punch out parts virtually to perfection, with no burrs and no sheet marking. The steel strippers have a wide holding surface that prevents cornering issues, ensuring stable punching and smooth blank removal. By using Marathon Plus, we are getting more productivity out of our presses and we’re extending their useful life.”

SFI, Inc., 1730 N. Forsyth Road, Orlando, FL 32807, 407-834-2258, Fax: 407-834-2295, info@sfiinc.com, www.sfiinc.com.

Mate Precision Tooling, 1295 Lund Boulevard, Anoka, MN 55303, 800-328-4492, Fax: 800-541-0285, marketing@mate.com, www.mate.com.