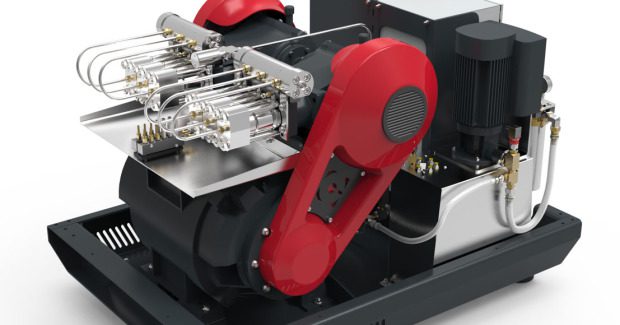

Ultra-High Pressure Direct-Drive Pump

This 100 hp direct-drive pump from OMAX uses EnduroMAX® technology to improve reliability and lower operating costs by delivering JetPower at the nozzle that is equal to 135 hp intensifier designs.

Posted: September 18, 2014

At IMTS 2014, OMAX® Corporation (Kent, WA) revealed its new 100 hp direct-drive pump with EnduroMAX® technology in Booth N-6228. Show attendees discovered how the pump provides increased efficiency, improved reliability and lower operating costs by delivering more JetPower at the nozzle, equal to today’s 135 hp intensifier designs.

The 100 hp direct-drive pump features the durable Inline 6 design, an evolution of the company’s EnduroMAX design that provides smooth cutting, high reliability and easy modular maintenance. The addition of the 100 hp model extends the line of EnduroMAX pumps, which includes 30 hp, 40 hp, and 50 hp models.

The 100 hp pump with EnduroMAX technology increases efficiency by delivering 30 percent more horsepower to the cutting nozzle, compared with a 100 hp intensifier pump. This increase in JetPower creates a more powerful abrasive stream for faster cutting speeds and higher productivity, and the improved efficiency results in less wear and tear and maintenance. The pump provides a stable jet stream up to eight times smoother than intensifier pumps, significantly reducing wear on high pressure plumbing and fittings.

The 100 hp pump also uses variable frequency drive (VFD) technology that tailors power and water consumption to an application for powerful and precise cutting. With VFD technology, the 100 hp pump has increased power and water efficiency and seamless pressure control, all while eliminating inrush current and reducing maintenance.

OMAX direct-drive pumps, which have been proven in over 3,000 installations worldwide, use less electricity and up to 75 percent less water than intensifier pumps, making them environmentally “green” and lowering operating costs and raising overall standards. In addition, their quiet operation makes for a safer working environment.

OMAX designs and manufactures the world’s most advanced abrasive waterjet technology in a variety of table sizes and price points at its headquarters in Kent. Backed by unmatched support and powered by the company’s intuitive control software, OMAX and MAXIEM® JetMachining® Centers bring affordable performance to a continuously expanding range of industries.

OMAX Corporation, 21409 72nd Avenue South, Kent, WA 98032, 253-872-2300, Fax: 253-872-6190, omax@omax.com, www.omax.com.