FABTECH 2014: Measurement, Metal Forming & Fabrication, Finishing

Here are some reviews of the measurement systems, metal forming and fabrication equipment and finishing tools being exhibited at this year’s show.

Posted: October 9, 2014

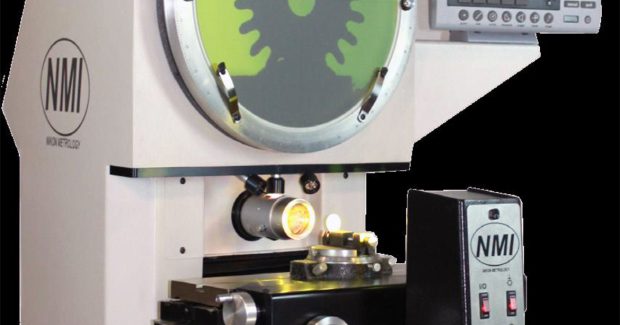

OPTICAL COMPARATOR MAXIMIZES MEASURING FLEXIBILITY

To measure is to know, and with superior optics and maximum resolution to 0.0005 mm (0.00002 in) on both X and Y axes, the new H14L optical comparator from Nikon Metrology Inc. (Brighton, MI) helps users know precisely what they’re measuring in Booth B-1155. With a high-contrast, coaxial through-the-lens surface illumination system, the H14L produces bright, crisp, photo-like surface reflection images from edge to edge. Nikon optics from 5X up to 100X provide unsurpassed accuracy and repeatability while a new, ultra-bright LED illumination system offers through-the-lens surface, oblique surface, and contour illumination options.

Work area dimensions are 300 mm (12 in) X-axis manual movement with glide release, 150 mm (6 in) Y-axis manual movement (rise/fall), and a 40 mm (1.5 in) focus adjustment stroke in the Z-axis. Vertical screen size is 360 mm (14 in) of viewing area. Rugged and durable with an extremely rigid steel housing, frame, and stage, a number of optional stage fixtures are available to accommodate specific sample requirements. www.nikonmetrology.com

CRIMPED RECTANGULAR FILAMENT FOR AGGRESSIVE FINISHING

In Booth B-640, Osborn (Cleveland, OH), a leading supplier of industrial brushes, announces its new crimped rectangular filament in silicon carbide and aluminum oxide on a complete line of ATB brushes. The new filament offers an ideal blend of aggression, flexibility and conformability for a variety of finishing applications, including automotive, off-road equipment, gear deburring, engine housing, aerospace, turbine blades and many others.

Osborn offers crimped rectangular filaments in both silicon carbide and aluminum oxide on ATB FastCut composite wheels, ATB Uni-Lok max density disc brushes, ATB Uni-Lok Turbo disc brushes and ATB Uni-Lok quick-change disc brushes. Silicon carbide filament brushes are ideal for use on high-silica aluminum, ductile iron and high-carbon steel. Aluminum oxide filament brushes are ideal for use on Inconel, Hastalloy and Rene alloys.

The company also introduces its redesigned, high-speed, knotted-wire cup brush that features a taller inner cup that forces the brush to be used on the filament tips, rather than bending. Featuring the highest quality AB wire in the industry, threaded-nut connection and aggressive knot style, the redesigned cup brush offers premium performance. These knotted-wire cup brushes are rugged and efficient tools for heavy-duty cleaning of metal surfaces and are specially designed for use on portable tools and filled with steel-wire filament for rigorous applications.

A demonstration of the high-speed, knotted-wire cup brush from Osborn.

Osborn is a leading supplier of surface treatment solutions and high-quality finishing tools for hundreds of industrial and commercial applications such as metal finishing, honing and surface polishing. Founded in 1887, the company now includes operations in 15 countries and serves customers in more than 100 countries. A unit of Jason Inc., Osborn carries more than 10,000 standard products and more than 100,000 customized solutions to serve a diverse group of customers and industries. osborn.com

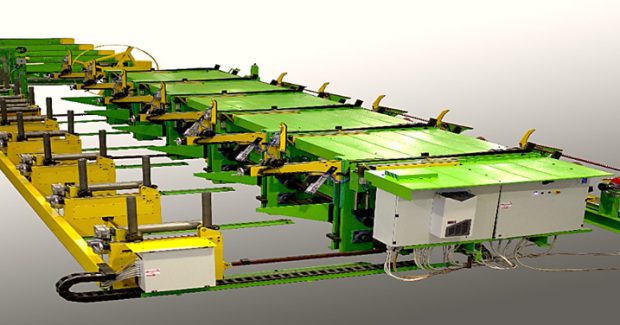

NEW TECHNOLOGY FORMS BUNDLES OF TUBES

In Booths B-4952 and C-350, Pat Mooney Inc. (Addison, IL) will be introducing OMP Bundling Lines that bring new technology to forming bundles of tubes. These systems can suit every production environment from hexagonal, square-to rectangular bundles up to 7,700 lb of weight. Operation and installation is managed in a short time frame, enabling the shop to have its bundling system ready and productive in a short period of time.

A demonstration of ann OMP Bundling Line from Pat Mooney.

The machine’s operation is controlled by a PLC system and has a modular design allowing it to limit the amount of cables needed for installation. This system encompasses several advantages both during the startup and installation and then in operation.

Established in 1949, Pat Mooney is proud to be a third generation family-owned and operated business. Our reputation in the metal sawing industry is based on introducing innovative metal sawing equipment and blades, providing responsive customer and technical support and supplying spare parts for the equipment we sell. www.patmooneysaws.com

MAXIMUM POSITIONING ACCURACY IN HEAVILY CONTAMINATED ENVIRONMENTS

In Booth B-3405, the newly enhanced IMS-I integrated measuring system from Bosch Rexroth Corporation (Charlotte, NC) now achieves maximum positioning accuracy in heavily contaminated work environments. The compact solution for ball and roller rail systems has an inductive design that offers repeatable accuracy performance equivalent to that of more expensive glass scale systems. The incremental IMS-I provides feedback for distances of up to 4,500 mm and allows several runner blocks to be positioned independently of each other on the same rail.

Whenever cooling lubricant and chips are introduced in the working environment or strong electric and magnetic fields disrupt sensor operation, designers and engineers require a travel measuring system that is as robust as it is accurate. The advanced IMS-I integrated measuring system is a great compact alternative which is rated for a positioning accuracy of 0.25 µm. It features a high-precision pitch etched into a steel strip. The scale is integrated into the profiled rail and protected by a tightly welded stainless steel strip across the entire rail section length. The tightly welded connection is capable of resisting extreme vibrations and impacts of up to 10 g, and a highly sensitive evaluation electronics system is integrated into the runner blocks to facilitate position sensing close to the tool center point.

Additional external accessory attachments are not needed, which allows the integrated measuring system to fit into tight spaces with minimal effort and making it possible to achieve straightforward, minimal footprint machine designs and eliminate additional machine bed preparations needed for traditional alternatives.

The IMS-I optimizes the distance between the sensor and scale to further improve the system’s ability to withstand the negative impacts of chips, dust, dirt, and contamination. The inductive measuring system operates without physical contact and is therefore a wear-free assembly. Travel paths of up to 4,500 mm can be measured with ease; the user can position several runner blocks independently of each other on a single profiled rail and the system will detect each position with exacting precision.

Repeatability accuracy levels attain 0.25 µm and scale precision is ±3 µm/m, both of which allow the IMS-I to offer almost identical performance to that of a glass scale. Unlike the latter, the IMS-I, with its IP 67 protection rating, does not require any additional sealing or further contamination protection, thereby reducing overall system and operating costs. The entire IMS-I sensor system is integrated into all versions of the company’s ball and roller rail systems to minimize assembly and servicing effort. The interchangeable rail system design means all runner blocks of corresponding sizes and configurations can be mounted to profiled rails of different accuracy classes, along with the IMS-I. Not only does this simplify the logistics of the commissioning process, but also makes exchange and replacement easy to minimize machine downtime.

The IMS-I comes preconfigured for direct connection to IndraDrive servo drives from Rexroth and all other commonly available servo drive assemblies, and is able to handle both analog (1 Vss) and digital (TTL) signal types. www.boschrexroth-us.com/dcl

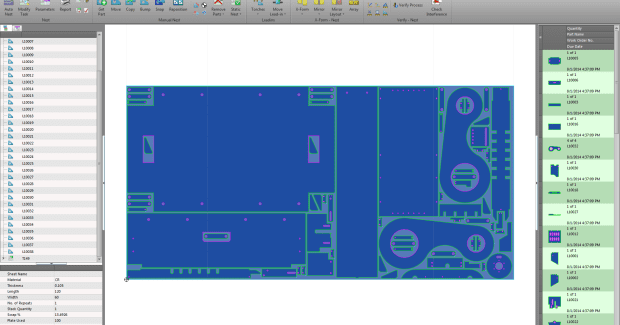

HIGH TECHNOLOGY PRESS BRAKES, FIBER LASER CUTTING

In Booth B-3125, the new B3 series of press brakes from Salvagnini America, Inc. (Hamilton, OH) combine direct drive electric motors for speed and new hydraulics for power to significantly reduce cycle times while providing an exemplary, repeatable level of accuracy – within 2 microns of perfect. B3 press brakes incorporate a package of proprietary technologies and automated features that differentiate these press brakes from the common legacy products. Every B3 uses a Kinetic Energy Recovery System (KERS) to reduce consumption by recovering and reusing energy expended on the down stroke. This is the same advanced technology pioneered for use in Formula 1 racecars.

http://youtu.be/RYxAUTU1gu0

An overview and demonstration of the B3 series of press brakes from Salvagnini America.

The proprietary SiX controller uses the same proven software technology – PresStudio – that guides the company’s panel benders. PresStudio contains the familiar Jobs List, Maintenance Manager, and Easy Data programs, among others.