FABTECH 2014: Welding, Cutting Systems

Here are some reviews of the welding equipment and cutting systems being exhibited at this year’s show.

Posted: October 14, 2014

COMPLETE RESISTANCE WELDING PROCESS CONTROL

In Booth C-2216, the new hand-held Weldscope WS-100 from Dengensha America Corporation (Bedford, OH) is designed to ensure the accuracy and detail required by high-quality manufacturers. From the palm of the hand, it controls 15 monitoring functions and 3 selectable detection ranges.

The Weldscope WS-100 offers manufacturers a wide range of other features and benefits as well. It generates upper and lower limit error signals, “Good” and “No Good” output signals, and it detects secondary cable wear. It also incorporates a waveform display, a zoom function, torodial coil, florescent display, multiple output options, and a lithium backup battery. Along with the capability to better control quality and accuracy by monitoring resistance welding processes, the Weldscope WS-100 also gives the user the ability to save the last 800 welds and then print them by way of direct cable or Bluetooth to a PC.

Dengensha America Corporation offers automotive, agricultural and general manufacturers the most complete line of resistance welding equipment in the world, including projection and spot welders; weld guns, feeders and controls with consumables, and spare parts. Training and field service complete a single source capability. www.dengensha.com

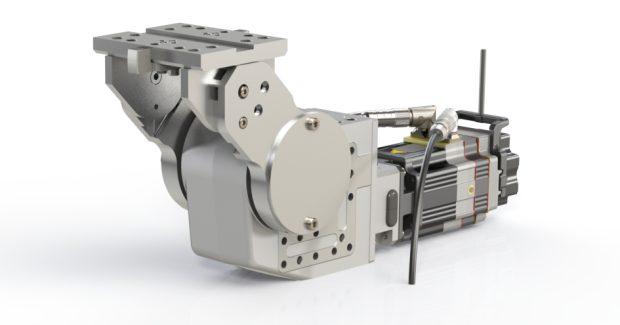

ELECTRIC PIVOT FOR BETTER CONTROL OF ELECTRODE TIP DRESSERS, CLAMPS, TOOLS

In Booth C-3666, DE-STA-CO (Auburn Hills, MI) introduces a new electric pivot unit that is smaller and lighter than traditional pneumatic units, while providing uniform torque and enhanced versatility. The 98W Electric Pivot Unit enables manufacturers to add a pivot in tight spaces and gain better operational control of electrode tip dressers, clamps and other tools.

“With a pneumatic pivot unit, torque can vary greatly depending on the opening angle,” says Prasad Tumati, the global product director of clamping technology for DE-STA-CO. “An electric motor provides a constant torque level throughout the entire range of motion. This allows for smoother, more precise operation. Plus, the electric setup is more energy efficient and offers greater versatility.”

Since it utilizes a worm gear instead of a pneumatic toggle mechanism, the 98W Electric Pivot Unit can rotate its arms a full 360 deg. The pivot features a new design that permits the saddle arm mount to be adjusted in 45 deg increments, enabling users to easily change the pivot angle without swapping the head of the unit. The 98W Electric Pivot Unit can operate in two modes: programmed setting with limited opening angles or infinite opening angles. It is compatible with multiple motors and can be interchanged with common pneumatic pivot units equipped with 125 mm 160 mm or 200 mm cylinders.

“The wide-ranging abilities of this single unit make it capable of replacing several different sizes of pneumatic units,” says Tumati. “Instead of trying to match the right pneumatic pivot to their needs, users can just install the 98W Electric Pivot Unit and know it will offer superior performance over a wide range of operating conditions.” With 500 Nm of torque, the 98W Electric Pivot Unit is well suited for a variety of applications. It requires only four seconds or less to rotate its arms 135 deg.

DE-STA-CO is a global automation and workholding company that has provided productivity solutions to the manufacturing industry since 1915. destaco.com

COMPACT, AUTOMATED CUTTING MACHINE FOR PLASMA AND OXY-FUEL CUTTING

ESAB Cutting Systems (Florence, SC) introduces SGX, a compact, automated cutting machine for plasma and oxyfuel cutting in Booth C-2466. The system is designed with leading-edge technology made affordable for the small fabricator or manufacturer.

A demonstration and overview of the compact SGX automated cutting machine for plasma and oxyfuel cutting from ESAB.

Advanced features include the easy-to-use Vision® T5 touch-screen CNC with built-in automatic nesting, as well as automatic gas controls and plasma automation powered by m3 Plasma technology. Performance and accuracy are assured with a heavy steel beam, precision machined mating surfaces, and linear rail. This rugged design ensures smooth motion, accuracy and long term machine durability. SGX enables higher productivity with rapid cut-to-cut cycle times through the integration of dual-side, high-speed AC drives and a fast torch lifter.

The compact design of the SGX cutting machine minimizes floor space requirements. One-meter rail increments keep the footprint small to maximize production space. Simple, automated operation is achieved with the built-in process database in the Vision T5 CNC, which fully integrates the company’s plasma and oxy-fuel process controls into an easy-to-use touch-screen interface.

Also standard equipment is an oxy-fuel gas control that automatically switches between low preheat and high preheat pressure, as well as ease-on cutting oxygen for piercing thicker materials. Gas controls are conveniently located at the side of the machine where the operator has easy access and can see the torches while making adjustments.

SGX can be configured with a wide range of plasma options, from simple air-plasma systems up to fully automatic 360 Amp multi-gas plasma systems. The machine can be equipped with m3 Plasma® for cutting up to 50 mm (2 in) thick mild steel. The m3 Plasma system achieves superior cutting results over a wide range of material types and thicknesses, and produces a high quality cut face with low dross, requiring little secondary clean up. It features an automatic gas control integrated with the process database on the CNC for fast and easy process setup without the guesswork.

SGX is available in sizes to cover plates up to 2,500 mm (8 ft) wide, and up to two 6,000 mm (20 ft) plates end-to-end. This new cutting system is offered with a choice of downdraft tables or water tables for dry or under-water plasma cutting.

For more than 75 years, ESAB Cutting Systems has been a total system supplier offering off the shelf, turnkey solutions to customers around the world, including CNC shape cutting machines in a variety of sizes, using a wide range of cutting technology to include plasma, oxy-fuel, laser, and waterjet tools, programming and nesting software, and CNC controls. www.esab-cutting.com

LIGHTWEIGHT TOOL CUTS SMALL DIAMETER STEEL, STAINLESS, CAST IRON AND PLASTIC PIPE

In Booth C-123, the powerful and lightweight PipeCut 170E from Exact Pipe Tools, Inc. (Cuyahoga Falls, OH), the U.S. wholly-owned subsidiary of Exact Tools Oy (Helsinki, Finland), perfectly cuts steel and plastic pipe. Ideal for the professional industrial pipe fitter, PipeCut 170E is a fast, easy, safe and precise way to cut steel, stainless steel, cast iron and plastic pipe. The cutting tool features adjustable speed and steady torque, providing high-end performance.

A demonstration of the PipeCut 170E from Exact Pipe Tools.

With seven different models available, including the PipeCut 170E, Exact Pipe Tools products are used in a variety of applications, including power generation, refinery and chemical plants, hospitals and facilities, home building and renovation, shipbuilding, pulp and paper, water and waste water systems, heating and cooling systems, gas installations and maintenance and repair.

Exact Pipe Tools has been developing revolutionary, market leading and patented pipe cutting machines since 1993. In 2013, Exact Tools Oy received the distinction of a Red Dot design award for high-quality design of its PipeCut 220E, 280E and 360E systems. www.exacttools.com

ROBOTIC ARC AND SPOT WELDING

In Booth C-2056, FANUC America Corporation (Rochester Hills, MI), a leading supplier of innovative automation solutions, will demonstrate intelligent robotic solutions for arc and spot welding, assembly, bin picking, and STEM education. They will also feature open CNC with a demonstration of third-party nesting on a FANUC CNC and highlight CNC solutions for fabrication operations on the Series 30i-B CNC. www.fanucamerica.com

HIGH PERFORMANCE MANUAL WELDER

With its TPS 600i in Booth C-1954, Fronius USA LLC (Portage, IN) is launching a new high-performance manual welding product. Perfect for heavy steel construction, repair work and the welding of thick wires in general, the first 600 amp welding power source inverter is also an excellent choice for arc air gouging. Going hand-in-hand with the tremendous performance are similarly conditioned system components.

At 500 A at 100 percent duty cycle, 600 A at 60 percent power levels, the physical characteristics of the system components must naturally also be up to the task: this is where the Power Connector earth connection developed for this power source comes in. With its rotating mounting it provides an ideally defined current transfer and prevents the loosening of the connection socket, which in turn prevents the socket from burning out.

The associated welding torch has an extremely high power consumption, which guarantees a duty cycle of 100 percent at 700 A using CO2 and argon gas. But that is by no means all: when the gas nozzle is connected, 100 percent of the water circulates through the gas nozzle; when it is disconnected, the integrated water stop prevents the water from escaping. The cooling system is also unique and new. It features a wear-free, brushless motor without any seals, meaning no cooling agent can enter the motor. In terms of power, the cooling system is designed for three-shift operation.

Two water-cooled wire-feed units tailored specifically to the power source are provided. These are also brushless and wear-free and are available by default as a 15 m/min version for wire diameters up to 2.4 mm and a 30 m/min version for wire diameters up to 1.6 mm. www.fronius-usa.com

JOB SHOP/ CONTRACT MANUFACTURING SERVICES

In Booth C-3536, Hangzhou Gegao Machine Co Ltd (Hangzhou, Zhejang, China) offers CNC laser cutting, plasma cutting, flame cutting, punching, stamping, bending, welding, assembling, machining (CNC lathes, milling, drilling, planning, grinding), surface treatment and packing, etc. The company’s main surface treatment services include sandblasting, powder coating, zinc plating, hot-dip galvanized, polishing, painting, heat treatment, chroming, etc. The company also has carbon steel, cold roll steel, hot roll steel, zinc plate, aluminum, stainless steel, alloy steel, grey iron, ductile iron or custom (0.5 mm to 355 mm), etc. www.gegao.com

DEBURRING/CHAMFERING TOOL, STRONG VISE

In Booth C-3422, Heck Industries (Hartland, MI) introduces the Turbo-Burr, their newest deburring/chamfering tool that is 20 percent lighter. This new tool weighs only 3 lb and offers all of the same features and benefits. The Turbo-Burr uses a standard carbide burr to remove burrs from sheared, plasma, or laser cut edges. The tool can be used on very thin materials up to large blocks. Cutter depth is adjustable from light burr removal up to 1/16 in chamfers at speeds up to 10 fpm.

A demonstration of the Turbo-Burr deburring/chamfering tool from Heck Industries.

Heck Industries is also the exclusive North American representative for the German-made Heuer Bench Vise, which is constructed from a “Made to Take a Beating” forged steel frame that is 35 percent stronger than standard cast iron. This new vise features snap-in jaws for holding even the most delicate items. With sizes ranging from 4 in to 8 in, there is a vise for every bench. www.heckind.net

FILLER METALS IMPROVE PRODUCTIVITY AND QUALITY

In Booth C-2934, Hobart Brothers Company (Troy, OH) will showcase its filler metals designed to improve quality and productivity in fabrication and manufacturing welding applications. In addition to live welding demos, welding specialists will be available to answer questions and provide product advice to visitors.

Filler metals of interest at the show include MEGAFIL® seamless wires that are available in flux-cored and metal-cored varieties. These wires feature a unique seamless design that resists moisture pickup to reduce the risk of hydrogen-induced cracking.

An overview and demonstration of MEGAFIL® seamless wires from Hobart Brothers.

Element™ low manganese wires are gas-shielded flux-cored wires that feature the lowest manganese levels of any similarly classified filler metal in the marketplace and are designed to help companies maintain compliance with environmental regulations. Ideal for high volume manufacturing and welding in confined areas, Element filler metals also offer robust mechanical and chemical properties for high performance welding.

MaxalMig 4943 aluminum filler metals include MaxalMig solid wires and MaxalTig cut lengths that are formulated for applications with the same weld procedure specifications as 4043 and 4643 products, but do not depend on base metal dilution to increase weld strength. These filler metals also feature low welding smut and discoloration, provide excellent corrosion resistance and offer low cracking sensitivity in most applications.

Hobart Brothers is a leading manufacturer of the innovative Hobart® brand of filler metals, and is a wholly-owned subsidiary of Illinois Tool Works, Inc. (Glenview, IL). www.HobartBrothers.com

UPGRADE WITH BOLT ON WELDING CONTROLS

Get your welding motion under control using the new Jetline 9700 Series of bolt on controls from Jetline Engineering (Irvine, CA) in Booth C-2638. The 9700 series is an updated platform that replaces the 9600 family of products. Using the latest microprocessor technology coupled with an advanced user interface, weld motion control is at your gloved finger tips. The 9700T can handle either linear or circumferential travel. The 9700W is specially designed for both cold and hot wire GTAW/PAW applications.

These controls have the same mounting footprint and remote interface as the 9600 to allow easy backward compatibility on existing systems. The 9700 series of controllers are perfect for upgrades or retrofitting of existing equipment regardless of who the original manufacturer may have been. The 9700T will control speed, start/stop delays, and the weld sequence initiation on both longitudinal travel and circumferential travel setups. The 9700W is the control for a stand-alone cold or hot wire GTAW/PAW set up. www.jetline.com