FABTECH 2014: Welding, Tube & Pipe Fabrication

Here are some reviews of the welding systems and tube and pipe fabrication machinery being exhibited at this year’s show.

Posted: October 9, 2014

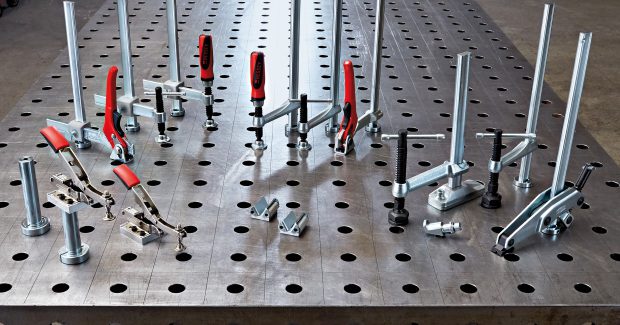

With its TW28 range, the company offers clamping elements with two throat depths: either 4-3/4 in or 5-1/2 in, and a clamping capacity of up to 12 in. If you require even more flexibility when clamping, the solution for this lies with the clamping elements in the TWV28 range. The TWV range has a variable throat depth that can be adjusted by hand. Both series are characterized by a tempered profiled rail and sliding arm for strength where you need it, as well as the option to choose between three handle variants. The versions with the high quality 2-component plastic handle and the T-bar have a smooth-running ACME spindle. The lever handle variant with an indexing mechanism ensures controlled, fast and vibration-proof clamping.

The TW28GRS welding table clamp has the spindle located behind the rail. This ensures free access to the work area and protects the spindle against welding spatter. This benefit is particularly noticeable when clamping with the tightest of space constraints, in narrow openings as well as for short projections. The TW28GRS unit can pivot and are adjustable in terms of height. The sturdy V-grooved pressure plate also enables round or square work pieces to be clamped.

BESSEY® has been a market leader in clamps since 1936. www.besseytools.com

3D TUBE CUTTING MACHINE UP TO 8 INCH DIAMETER

In Booth C-922, BLM Group USA Corporation (Wixom, MI), a global leader in the manufacture of tube processing solutions, will display its wide range of equipment, featuring its LT8 machine and an array of other tube fabricating equipment in the exhibit.

The LT8 is a three-dimensional laser tube cutting machine that provides flexibility and ease of use in extremely precise laser cutting of tube diameters from 12 mm to 220 mm (0.5 in to 8.8 in) and bar weight up to 35 kg/m (77 lb/39 in). The unit is equipped with a rotating head that provides for three dimensional, five-axis cutting and features an automatic loading system combined with a unique unload, increasing the productivity of most operations. Complex processing such as cutting different pieces on the same bar or batch changing among bars is managed automatically.

A demonstration of the LT8 3D laser tube cutting machine from BLM Group.

Information will also be available on the LT5, an entry level automated laser tube cutting system designed to handle small and medium-sized tubes, the all new 4Runner tube bender designed specifically for HVAC applications, the ELECT all electric tube bender, the ETurn right hand, left hand all electric tube bending machine along with the LT JUMBO laser tube cutting series.

Thanks to the versatility of its advanced 1 kW IPG fiber laser, the new LT5 can efficiently process mild steel as well as highly reflective materials such as aluminum, copper, and brass. The system’s fiber laser provides a dramatic improvement in energy efficiency when compared to the more traditional CO2 laser, leading to as much as a 50 percent reduction in hourly operating costs.

The ELECT all-electric 12-axis tube bending machine provides productivity, flexibility and accuracy to bending of large diameter (up to 150 mm/6 in) tube, making it the ideal choice for many demanding operations. The LT JUMBO Series, is an automatic laser tube cutting system designed to bring higher levels of precision to large diameter, thick walled tubes.

BLM Group is a global leader in tube processing solutions, including laser cutting, cold sawing, bending, end-forming, and tube measurement equipment, as well as wire bending machines, with more than 50 years of tube experience and thousands of tube fabrication applications. www.blmgroup.com

MODULAR WORKSTATIONS

In Booth C-1730, Bluco Corporation (Aurora, IL) will be displaying its line of workstations to complement their existing modular fixturing solutions. With the ability to quickly set datum locations within ±.030 in and repeat setups within ±.005 in, weldments are within tolerance every time with no costly rework delays. The workstations can be used as stand-alone weld cells, or for sub-weldments to feed work to larger weld cells.

http://youtu.be/_GdYNfr5mWI

An overview and demonstrations of the Bluco modular fixturing system.

Bluco workstations are available with stationary or mobile bases and come with pre-configured tooling kits. Hands-on tooling displays will be available and application engineers will be on-site to discuss your customized application. Visit the booth to learn how their modular tooling can benefit your company. www.Bluco.com

ZIPPER WELDER MAKES TANK FABRICATION EASY

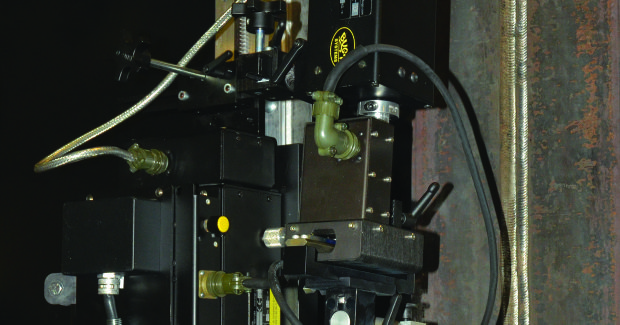

In Booth C-2106, the new track system from Bug-O Systems (Canonsburg, PA) for welding vertical seams on field storage tanks is an easy to use, affordable system that easily mounts to the top lip of a tank, increases welding production and incorporates the MDS System, then quickly glides to the next joint.

The zipper welder premise is quite simple. By being able to hang the rail system over the top of the tank and use only minimal magnets, it makes fit up time fast and effective. It is also able to roll across the top of the tank removing the trouble of picking up our system and moving the system from weld to weld cutting down setup time, thus increasing productivity and profits. It is used in conjunction with the company’s modular drive system, which enables the user the option of a linear weaver or pendulum weaver for vertical welding applications.

The zipper welder is also a cost effective and great alternative for vertical joints if a shop does not want to step up to some of the larger tank fabrication equipment. www.bugo.com

PUT MATTE, SATIN, MIRROR FINISH ON STEEL, STAINLESS, NONFERROUS METALS

In Booth C-2652, the new and improved PTX Eco Smart Professional Surface Finisher from CS Unitec, Inc. (Norwalk, CT) is designed with a more powerful motor for producing matte, satin and other fine surfaces up to a mirror finish on steel, stainless steel and nonferrous metals. The tool’s high torque, 1710 watt, 15.5 amp motor makes the PTX Eco Smart ideal for coarse grinding jobs such as removing welds, deep scratches, oxidation, rust and paint. It can also polish inside corners. Variable speed control from 1,000 rpm to 3,800 rpm with tachogenerator provides constant speed, even under load. The handle is adjustable for right- and left-handed users.

A demonstration of the PTX Eco Smart surface finisher from CS Unitec.

The PTX Eco Smart has a patented abrasive mounting system that saves time, reduces costs and eliminates vibration. This unique system allows grinding and polishing wheels to be changed in seconds, without tools or hardware. The hollow-core abrasive wheel simply slides onto the PTX Eco Smart’s finned, rigid rubber shaft. It then secures itself automatically when the machine turns. The finned shaft design of this finisher makes it vibration-free during operations and ensures 100 percent concentricity. A wide selection of hollow-core abrasives is available for this linear grinder. www.csunitec.com