GF Machining Solutions Receives Award

Its Integrated Vision Unit received the Golden Micron Award for micro technology innovation.

Posted: October 25, 2014

GF Machining Solutions (Lincolnshire, IL) recently received the Golden Micron (Microns d’Or) Award at Micronora 2014, a biennial micro technology and precision trade show held in Besançon, France. The award program recognizes micro technology innovations that make their official debut at the show.

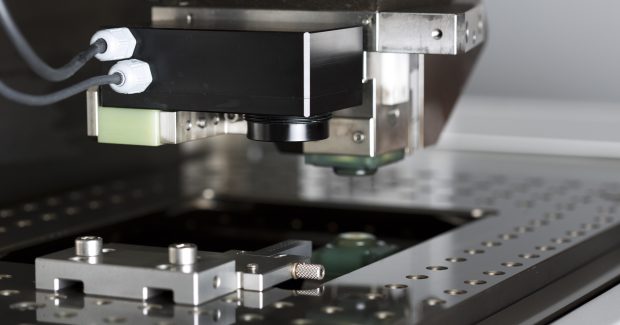

GF Machining Solutions stood out for its Integrated Vision Unit (IVU), a newly developed non-contact, vision-based measurement system that improves productivity, accuracy and cost efficiency in micron-scale wire EDM operations.

At the trade fair, the company integrated the IVU with its AgieCharmilles CUT 2000 S, which is the fastest wire-cutting EDM solution on the market. The machine features an Intelligent Power Generator (IPG) with Direct Power Supply (DPS) module that been shown to reduce machining time by 30 percent and produce high-quality surface finishes of Ra 0.08 µm.

When integrated with the machine, the IVU system helps overcome the limitations and cost issues of on-machine part location with the EDM wire. The system locates the part edges and scans contours with a charge coupled device (CCD) camera featuring a light-sensitive pixel array.

The camera, available with either a 56X or 156X magnification, employs two light sources – an incidental source at the camera lens, and a backlight source to enhance contrast – and converts the light intensity value for each pixel into an electronic signal with a corresponding value for each pixel.

At 56X magnification, the field of view is 0.24 in by 0.14 in and measurement accuracy is +/- 0.00006 in µm. The 156X camera has a 0.078 in by 0.05 in field of view and provides measurement accuracy of +/- 0.00004 in.

With its larger field of view, the 56x magnification camera is appropriate for measurement of larger parts, while the 156X magnification provides accuracy essential for measuring micron-scale parts. Typical users of the system, such as manufacturers in the micro stamping industry, most often choose the higher-magnification camera to maximize precision.

GF Machining Solutions also received the Golden Micron Award in 2004 and 2006. According to Gisbert Ledvon, the director of business development for GF Machining Solutions, AgieCharmilles has long been known to set the benchmark in EDM innovation. “This third honor at Micronora recognizes the brand’s commitment to pioneering new technology and the continuous improvement of EDM machine performance,” he said.