Milling Cutter Optimizes Aluminum Machining

The PCD Monoblock MB-X3 milling cutter from Lach Diamond uses a direct cooling system combination that can reduce cycle times up to 50 percent and more.

Posted: October 11, 2014

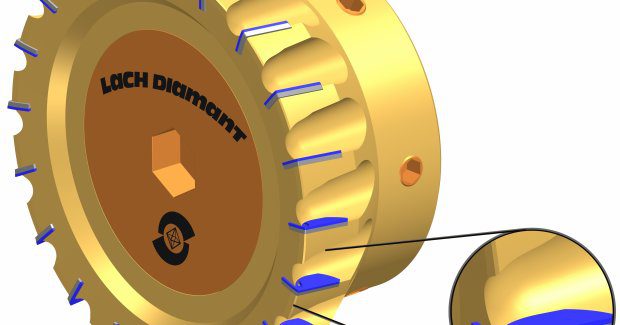

At first glance the newly developed PCD Monoblock milling cutter MB-X3 resembles a turbo impeller in the Lach Diamond, Inc. (Grand Rapids, MI) high-tech milling cutter line. The design of this tool, with a maximum number of cutting edges, makes it a reliable and dependable implement for optimum aluminum machining.

The MB-X3 allows feeds up to 40.000 mm/min and depths of cut up to 8 mm with maximum cutting speed. A cycle time reduction of 50 percent and more is possible.

All told, the PCD Monoblock milling cutter MB-X3 for face and square shoulder milling is another success for “Cool Injection,” a direct cooling system in combination with the chipbreaker “Plus” that makes the performance of this PCD tool unrivaled and superior.

For all of these reasons, “Cool Injection-Plus” is recommended for the innovative machining of aluminum in the automotive industry, for example, for engine and transmission housing manufacturing, and is especially suited for delicate components as well. Defects due to chip impact and ensnarled chips are eliminated.

Lach Diamond Inc., 4350 Airwest Drive SE, Grand Rapids, MI 49512, 616-698-0101, Fax: 616-698-0232, sales@lachdiamond.com, www.lach-diamond.com.