Steel Turning Grades for Machining Transmissions

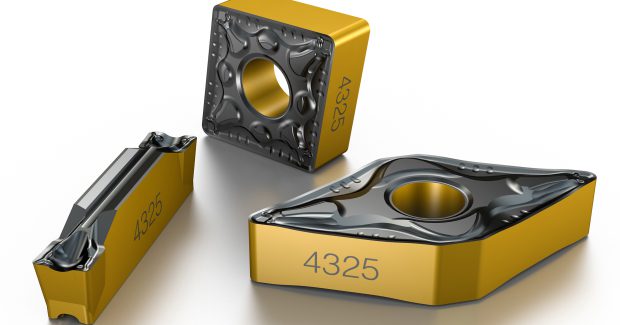

Grades GC4315 and GC4325 with Inveio from Sandvik Coromant are ideal for soft stage turning that comes before case hardening.

Posted: October 11, 2014

With new technological developments emerging on the automotive horizon, manufacturers are faced with extremely high demands in terms of quality, security and productivity. The new Sandvik Coromant (Fair Lawn, NJ) grades GC4315 and GC4325 with Inveio™ are designed to support the automotive industry with outstanding reliability and process security.

Transmission manufacturing is a large volume production with a low cost per part. Therefore, requirements such as high process security, short cycle times and consistent quality are critical for achieving faster lead times and lower production costs.

Soft stage turning is performed before the case hardening process. Offering high wear resistance and excellent tool life, this is where the steel turning grades GC4315 and GC4325 are to show a marked step up in performance.

http://youtu.be/SqHLLCeSQwI

GC4325 manages interrupted cuts and uneven depths of cut at high speeds in tougher steel turning.

The first choice grade for soft stage turning in stable conditions, GC4315, is designed for high-speed steel turning with a long and predictable tool life. Grade GC4325 is a tougher steel turning grade that manages interrupted cuts and uneven depths of cut at high speeds.

Both grades enable high cutting data without sacrificing component quality. If the spindle speed limit prevents the full use of their capacity, maximum productivity can be achieved by applying higher feed rates. These two grades are excellent choices for outer-diameter turning, copying and profiling and guarantee predictable performance for secure transmission manufacturing.

The company is a global leading supplier of cutting tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development we create unique innovations and set new productivity standards together with our customers.

These include the world’s major automotive, aerospace and energy industries. Sandvik Coromant has 8,000 employees and is represented in 130 countries. We are part of the business unit Sandvik Machining Solutions within the global industrial group Sandvik.

Sandvik Cormant US, 1702 Nevins Road, PO Box 428, Fair Lawn, NJ 07410, 800-726-3845, us.coromant@sandvik.com, www.sandvik.coromant.com.