Advances in 3D Metrology and Automation

A review of some of the current advances and application capabilities in measurement and inspection technologies.

Posted: November 7, 2014

3D INSPECTION PROFILING FOR PARTS MEASUREMENT

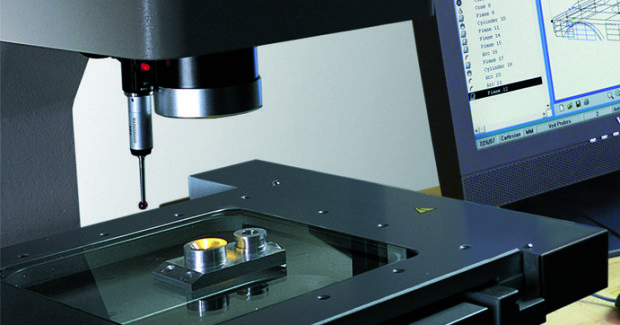

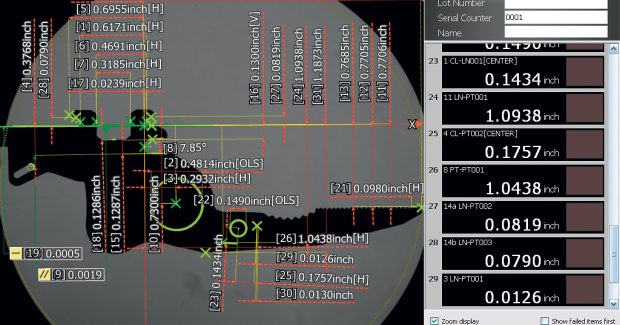

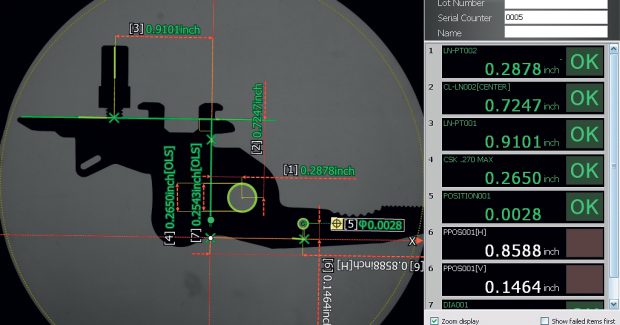

Offering 3D Profiling capability to inspection measurement, the versatile IK 5000 QUADRA-CHEK PC software system from Heidenhain Corporation (Schaumburg, IL) gives operators the ability to quickly measure and determine parts profiles within desired tolerance zones. This optional 3D feature compares the actual measured part to a three-dimensional model within the PC software, making inspection a breeze, especially useful on CMMs.

To utilize the 3D Profiling, the operator first imports a computer-generated 3D model using IGES or STEP formats and then takes measurement points on the desired part. This new function fits and compares the two within the IK5000, and then both the overall profile and the individual point results can be toleranced, printed, and/or exported for evaluation. The measurement and evaluation routines of 3D contours using the IK 5000 makes inspection on CMMs and multisensory measurement inspection machines an easy process. These part programs can then be used to take measurements of subsequent parts either manually or in an automated measuring process depending on the machine design.

Other functions of the 3D Profiling option include the ability to orient and align the model in all possible degrees of freedom, as well as to apply profile tolerances for any of the lines and surfaces either as an overall tolerance or specific to individual features or surfaces. It can provide measurement and graphic evaluation of 3D contours using multi-sensor and tactile measuring machines and is able to import a 3D CAD file (either STEP or IGES) and compare it with the actual measured part.

The IK5000 software is a PC-based inspection software and hardware package, used for 2D and 3D measuring tasks. The 3D Profiling add-on option is integrated into the standard operating software of the IK5000, allowing use of the entire software package as normal and turned on when needed. The IK 5000 QUADRA-CHEK with 3D Profiling is an equally suitable choice on new inspection equipment as well as for retrofitting onto an older inspection platform. Available in versions for three and four axes, the optional expansions make it ready for all coordinate measuring technology applications.

Auto Focus functionality allows the desired search distance to be directly entered into the search distance field. Previously, the algorithm used the Teach function to determine the optimum search distance and Z-axis velocity depending on the camera frame rate, which could cause intermittent failures depending on the part surface and if it was significantly different from the surface used during the Teach process.

Part Programming supports compensation for the thermal behavior of products that experience a shrinkage or growth of material during the manufacturing process. This allows users to write a single inspection program for measuring parts with materials having a known growth or shrink rate throughout the manufacturing process.

The Radial and Palletize automatic part programming routines help users when there are common features or parts that repeat angularly, around a datum, or based on a palletized grid layout. On Video-Based Inspection machines, these improvements will retain specific video tool sizes and the positions needed for these measurements, and then repeat them based on the angle they are located around the datum or in reference to a linear layout. The Palletize grid functionality also allows the user to graphically select which parts in the grid are required for measurement, and only run the program in those locations.

The IK5000 version 2.96.2 offers compatibility for PCs using Windows 7 (32 bit) operating systems as well as Windows XP and Vista.

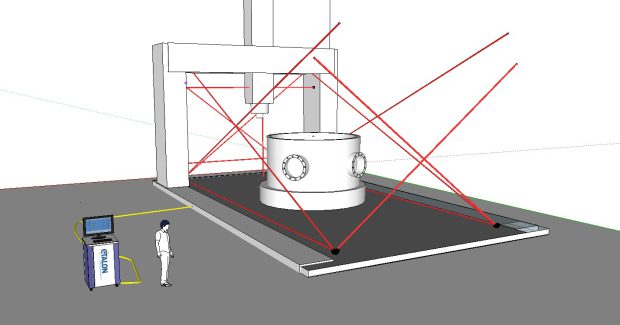

Oftentimes, many sensors are needed to measure certain dimensions such as the flatness of a large surface or the taper of a long part. Additionally, parts such as an engine block require a number of different style gauges to measure its critical features. To address these needs, the MSE 1000 modular multiplexor uses revolutionary multi-channel electronics for simple data acquisition that allows the user to plug in nearly any type of gauge and collect all the data in one location.

With the recent availability of the TTL, inductive and analog interface modules for the MSE, its true potential can now be reached, allowing connection for up to 250 devices and the acquisition of measured values via Ethernet, especially useful in production line measurement systems.

In its basic configuration, the MSE 1000 consists of a power module and a basic communication module. After that, it can be customized as needed. Additional modules can be attached to allow for the connection of incremental and absolute linear encoders, rotary encoders, a wide variety of LVDTs, and analog inputs. I/O modules and compressed air modules are even available for closed loop, automated in process gauging. The modules are easily mounted on a standard DIN rail in an electrical cabinet out of the way of the production line.

MSEsetup is provided with every system to allow the user to configure and master all the connected channels. MSEsetup also has diagnostics for connected sensors and MSE modules and allows automatic data transfer to a PC via Excel for basic data collection. If the application calls for further integration, the DLL files are made available for custom programming.

Heidenhain is the North American subsidiary of Dr. Johannes Heidenhain GmbH (Traunreut, Germany), a leading international manufacturer of precision measurement and control equipment. Our product line includes linear scales, rotary and angular encoders, digital readouts, digital length gages, CNC controls, and machine inspection equipment.

Heidenhain Corporation, 333 E. State Parkway, Schaumburg, IL 60173, 800-233-0388, www.heidenhain.us.