Advances in 3D Metrology and Automation

A review of some of the current advances and application capabilities in measurement and inspection technologies.

Posted: November 7, 2014

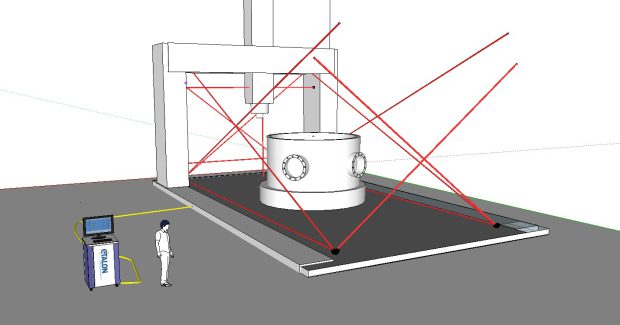

AFFORDABLE, PORTABLE 3D INSPECTION AND REVERSE ENGINEERING

Verisurf Software, Inc. (Anaheim, CA) offers the all New Master3DGage, an affordable and portable rapid 3D inspection and reverse engineering solution that enables machine shops to significantly increase production and improve part quality. The complete hardware/software solution delivers automated ‘in-process’ inspection right to the shop floor. Master3DGage quickly verifies manufactured parts directly to 3D CAD models or 2D drawings. When no data or drawings are available the Master3DGage is a powerful, easy to use reverse engineering solution.

“The New Master3DGage solution closes the loop in the digital manufacturing workflow,” said Ernie Husted, the president of Verisurf. “Manufacturers can not only extend a 3D model-based workflow from CAD to CAM to Computer Aided Inspection, but they can also reverse engineer parts into the 3D model-based process, thus improving quality, saving time and eliminating drawings.” Master3DGage integrates the latest Hexagon Metrology Portable CMM with Absolute Encoders with Verisurf X advanced 3D model-based inspection and reverse engineering software. The complete solution is a highly accurate and powerful toolset that is easy to learn, operate and maintain.

Rapid Three-Step Inspection

- Align: Align manufactured part to 3D CAD model by probing part to corresponding alignment targets on 3D CAD model.

- Inspect: Inspect manufactured part in real time by probing any surface or by following repeatable automated inspection plans.

- Report: Report inspection results in industry standard formats with intelligent GD&T and color deviation maps for clear, practical analysis.

Rapid Three-Step Reverse Engineering

- Measure: Contact scan or probe 3D complex profile surfaces or prismatic features including planes, cylinders, cones and spheres, or capture 2D features including lines, splines, circles and slots.

- Mesh: Powerful point cloud and STL mesh editing tools helps prepare large data sets for 3D mesh surfacing. In many cases STL models can go straight to 3D printing!

- Model: Transform 3D point clouds and meshes into 3D NURB surfaces or even solid models for precision manufacturing.

Master3DGage is available now from Authorized Master3DGage resellers worldwide and serviced by any Hexagon Metrology Service Center worldwide. Verisurf Software is a three-dimensional measurement solutions company committed to delivering advanced computer-aided surface analysis, inspection, tool building, assembly guidance and reverse engineering solutions.

Verisurf Software, Inc., 4907 East Landon Drive, Anaheim, CA 92807, 714-970-1683, www.Master3DGage.com, www.verisurf.com.

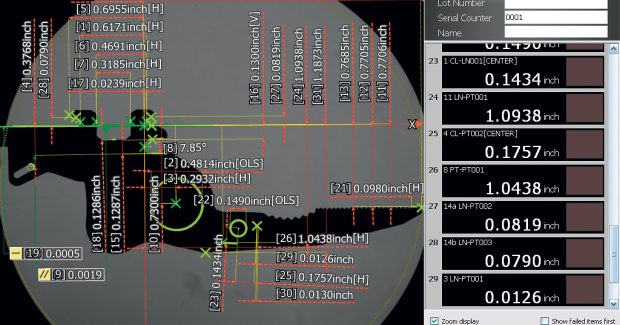

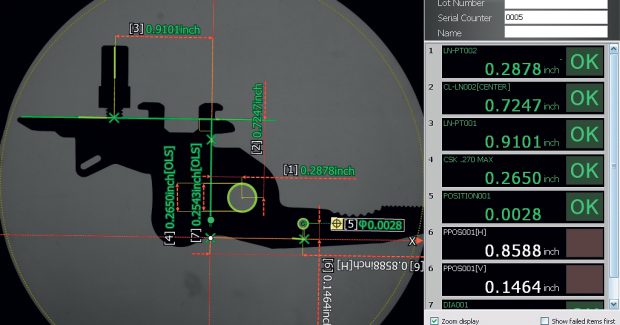

SIMPLE AND ACCURATE CONTOUR MEASUREMENT

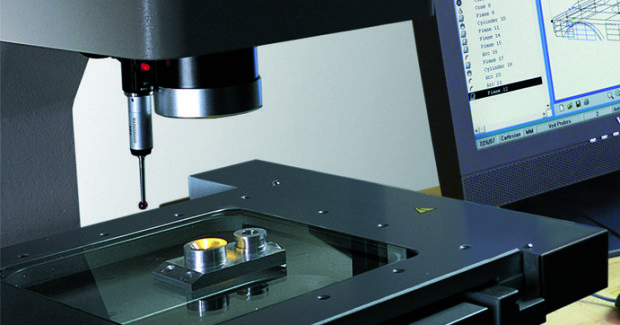

Mitutoyo America Corporation (Aurora, IL) offers the CV-2100N4 and M4 Contracer Form Measurement Instruments for quick, simple and accurate contour measurement. The operation keypad is located on the drive unit to improve set-up time and speed up high-volume repetitive measurement processes. Operations that are required for every measurement cycle, such as stylus position change, measurement start/stop and return, are easily accessible, reducing the workload of operators and increasing measurement efficiency.

The CV-2100M4 has a redesigned quick-vertical motion stand that allows operators to quickly and easily move the drive unit to and from the measurement height. This stand is equipped with reference stops for quick repositioning to the measurement height, ensuring efficient measurement flow. A jog shuttle control for variable speed horizontal movement of the drive unit is now a standard feature, allowing it to be easily moved into the measurement position. The CV-2100N4 is a detector unit only model designed for custom integration or for use with optional manual column stand.

The CV-2100N4/M4 detector unit (Z1-axis) is equipped with a highly accurate arc scale. This scale directly traces the arc trajectory of the stylus tip so that the most accurate compensation can be applied to the scale output, leading to higher accuracy and resolution. This highly accurate digital arc scale not only improves measurement accuracy, but also increases the measurement range of the detector to 50 mm.

CV-2100N4/M4 Contracers come with FORMTRACEPAK 5.4 contour analysis software that provides comprehensive measurement analysis and system control and includes surface roughness analysis, contour analysis, contour tolerancing, and inspection report creation. A wide variety of optional product accessories are available to ensure best fit and performance for any Form inspection application.

Mitutoyo is one of the world’s largest providers of measurement and inspection solutions, offering a complete selection of machines, sensors, systems and services with a line encompassing coordinate measuring machines, vision, form and surface finish measuring machines, as well as precision tools and instruments, and metrology data management software. The company’s nationwide network of Metrology Centers and support operations provides application, calibration, service, repair and educational programs to ensure that its 6,000+ metrology products will deliver measurement solutions for customers throughout their lifetime.

Mitutoyo America Corporation, 965 Corporate Boulevard, Aurora, IL 60502, 630-820-9666, Fax: 630-820-2614, info@mitutoyo.com, www.mitutoyo.com.