Laser, Waterjet, Plasma Cutting Systems

A yearend review of some of the current advances and application capabilities in each of these metal cutting technologies.

Posted: November 5, 2014

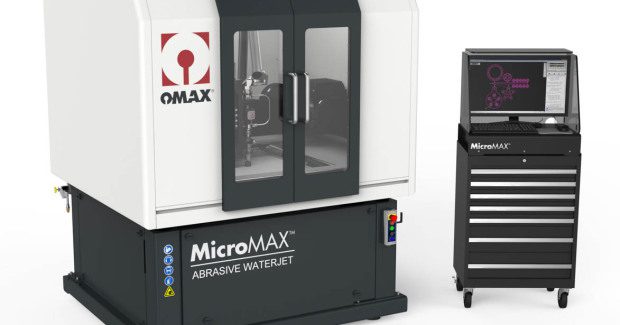

OMAX recently expanded its Intelli-MAX® Software Suite for JetMachining Centers with the release of Intelli-MAX 21, a new fourth generation cutting model that not only optimizes tool paths automatically, it gives users precise predictability as to cutting speeds, taper, jet lag and other abrasivejet factors of those particular tool paths. All of which takes abrasive waterjet cutting to the industry’s highest levels of speed and performance.

The cutting model within Intelli-MAX 21 builds upon years of real-world abrasive waterjet data accumulated through first and second-generation equation-based cutting models as well as from the massive data set of its third-generation model. The result is a cutting model that provides highly precise process and machine behavior predictions. Intelli-MAX Software updates bring performance enhancements to the company’s broad range of machine accessories. With version 21, Tilt-A-Jet users experience increased speed and accuracy when machining inside corners and small radii, especially in thick materials.

Based on customer feedback, Intelli-MAX 21 includes AutoPath command improvements, better import capabilities for DXF/DWG and PDF files, as well as enhanced memory for the 3D Path Editor. The software requires minimal operator training and makes it easy for users to create precision 2D and 3D parts faster and at a lower cost. “Whether it involves better file importing or expanding our parametric shape library for enhanced 3D cutting, we continuously update and improve our software so we can effectively support the diverse and changing needs of our customers,” said Carl Olsen, the lead software engineer for OMAX. “Intelli-MAX updates are free to machine owners for as long as they own their equipment.”

The company backs all Intelli-MAX Software updates with unparalleled support, continuously adding to and updating its software help screens, giving users access to more than 2,000 pages of tutorials, troubleshooting guides, videos, and tips and tricks, directly at the machine controller.

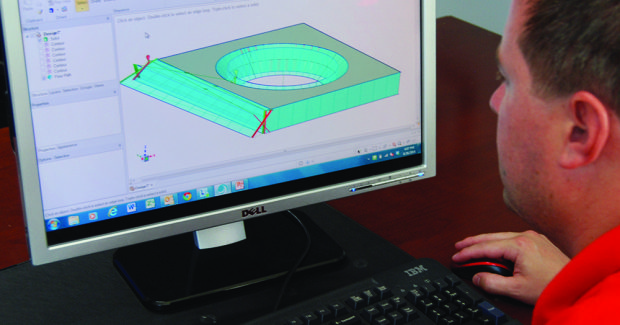

In related developments, OMAX and Spatial Corporation (Broomfield, CO), a leading provider of 3D development components for manufacturing applications, have combined their technologies to create what could be considered the market’s easiest-to-use 3D tool pathing solution. The Intelli-CAM™ software tool for JetMachining Centers generates 3D tool paths from solid 3D models as well as quickly performs 3D to 2D file conversions.

Intelli-CAM incorporates Spatial’s 3D InterOp to import CAD files from a variety of 3D sources, including CATIA, SolidWorks®, Solid Edge, Autodesk® Inventor®, Siemens® NX, Pro/E®, Creo® and much more. The software then applies custom solutions from OMAX and Spatial, such as the advanced AutoPath function or slice plane, to convert the geometry into full 3D paths suitable for waterjet cutting, ensuring the most precise part in the least amount of time and with minimal operator involvement.

With its user-friendly and powerful 2D conversion system, Intelli-CAM generates machine-ready cutting geometry through a few simple computer mouse clicks. With the 3D file imported, users extract the desired 2D profile directly from a slicing plane, shadow or face. Intuitive navigation tools make it easy for users to position and orient the slice – including rotations around all axes, orienting to a face, or projecting as a shadow.

Spatial’s 3D InterOp technology allows OMAX to provide extremely robust and proven 3D file import capabilities to JetMachining Center owners. “Our customers can now import practically any major 2D or 3D CAD drawing out there, which is especially beneficial to job shops because they often don’t know the original CAD system for a file,” says Olsen. “Plus, they don’t have to purchase expensive CAD software filter packages.”

Olsen also noted that customers doing 3D programming for 5-axis waterjet cutting will find Intelli-CAM greatly simplifies those operations, suggesting that it “may be the easiest to use 5-axis CAM software ever.” Intelli-CAM, which interfaces directly with the intuitive Intelli-MAX Software Suite, is available as a free update to JetMachining Center owners and is backed by the company’s unparalleled support.

Expanded taper control capabilities can be achieved through the popular A-Jet cutting head using the Intelli-MAX Software Suite for JetMachining Centers. A special feature within the intuitive software improves the performance of the A-Jet so it can make precise angled cuts and bevels and automatically correct for the taper normally found in an abrasive waterjet cut.

Programming for the A-Jet is largely automatic through the Intelli-MAX Software. Operators are able to choose the angle for part edges that require beveling, with cornering then handled automatically by the machine control. Operators also have a choice of piercing vertically to minimize splashing. With the new capabilities of the Intelli-MAX control software, operators can now choose between three types of taper compensation: full-control Manual compensation, quick Smart Taper compensation, and precise Intelli-TAPER® compensation. The A-Jet is designed to be retrofitable to existing machine models.

Several accessories are offered for JetMachining Centers to further increase their performance and versatility, including a Rotary Axis head that provides infinite rotation while cutting. The Rotary Axis is easy to program and has an expanded parametric shape library for enhanced 3D pipe cutting.

The accessory’s drive head allows for customized fixtures, and the versatile attachment design of the Rotary Axis enables users to position the head in various locations in the tank. Fully submersible and powered by common table controls, the rotary head does not require an additional power supply. The accessory also contains a built-in water drip sensor with warning lights and automatic shutdown. Additionally, the Rotary Axis is equipped with external grease fittings for easy maintenance.

OMAX designs and manufactures some of the world’s most advanced abrasive waterjet technology in a variety of table sizes and price points. Backed by unmatched support and powered by the company’s intuitive control software, OMAX and MAXIEM® JetMachining® Centers bring affordable performance to a continuously expanding range of industries.

OMAX Corporation, 21409 72nd Avenue South, Kent, WA 98032, 800-838-0343, sandra.mclain@omax.com, www.omax.com.

NEXT GENERATION SOFTWARE FOR FASTER, SMARTER PROGRAMMING

Flow International Corporation (Kent, WA), a leading developer and manufacturer of industrial waterjet machines for cutting and cleaning applications, has upgraded the FlowXpert™ Software Suite with FlowXpert 2015, which introduces significant new capabilities for 3D pathing and cutting which allow waterjet users to work more effectively in 3D, with less complexity.

FlowXpert 2015 is a robust 3D CAD/CAM software platform that expands on the 2D FlowMaster® intelligent Software Suite. The platform includes Design powered by Spaceclaim, an integrated 3D CAD/CAM programming tool with Flow Sequencer. With this release, the integrated CAD/CAM capabilities give users a seamless pathing experience. The integration with Flow Sequencer adds flexibility to users and is designed specifically for waterjet cutting, resulting in faster waterjet programming.

“By integrating these platforms we are providing users even greater flexibility in designing and pathing, which will have great benefits for both basic and complex waterjet parts,” explains Dr. Alex Chillman, the software and cutting platform manager at Flow. The software integration was engineered in partnership with Spaceclaim to take full advantage of Flow’s 40 years of waterjet application expertise and give users faster, smarter programming that is interactive. Incorporating best practices such as waterjet application tips, material cut speed knowledge, improved pathing algorithms and expanded lead in/out customization, the program estimates what steps are needed to get the best part.

The end result is a smarter, powerful, straightforward 3D system that lets users to do their work in fewer steps, with more intuitive design practices. The new FlowXpert 2015 includes functions familiar for current FlowXpert users, with a redesigned interface for intuitive 3D and 2D part programming. New capabilities in include:

- Integration of CAD Design powered by Spaceclaim with CAM Flow Sequencer modules.

- Waterjet specific geometry analysis means the part is ready faster.

- 3D CAM offset capabilities.

- Custom lead in/out available; or choose from an expanded lead in/out catalogue.

- Fast, versatile sheet metal processing from Spaceclaim.

- Advanced clean up tools that can be customized to your waterjet.

- Greater automation from smart pathing powered by Flow application expertise.

- Save your 3D model as a 2D programmed part.

All of this means users can now design a part and path it in the same program. Modifying the geometry of a part is now possible without losing the path, and in most cases the Sequencer integration will automatically update the path to accommodate the changes; a feature strongly requested by customers. In addition, the software will now detect model and path errors and suggest fixes. FlowXpert 2015 will be available in early 2015 globally.

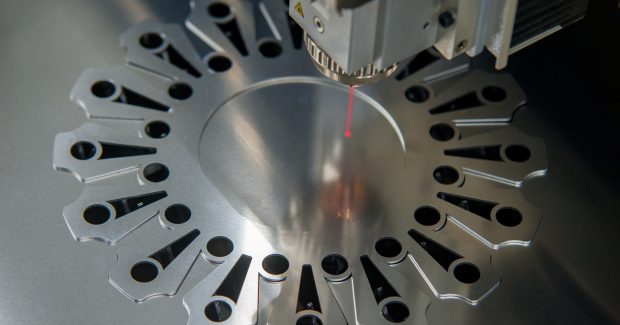

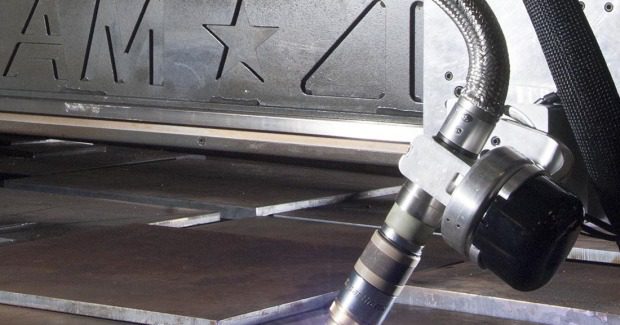

The company also offers the only non-contact material height sensing solution available in the industry, the DynaBeam™ Laser Sensing System. Exclusively from Flow, the DynaBeam provides superior accuracy to traditional height monitoring methods. “We are very excited to introduce the first non-contact precision height sensor to the waterjet industry,” said Dr. Mohamed Hashish, a senior vice president of technology at Flow. “With this advancement we continue to ensure that our customers have the most advanced tools for the highest productivity and accuracy of cut parts.”

Laser measuring is highly accurate without requiring physical contact with a material. The DynaBeam laser height sensing technology maps the natural state of materials, reducing the need for manual adjustment throughout cutting. Operators can choose between setting the standoff height between the waterjet nozzle and the workpiece before every pierce, or pre-mapping an entire workpiece quickly and easily. Used in combination with both Dynamic Waterjet® and Dynamic Waterjet XD for 2D and 3D bevel cutting the system ensures faster, more accurate waterjet cutting.

“The DynaBeam is a unique combination of waterjet cutting versatility and laser precision measuring capabilities,” adds Dr. Chillman. “Nozzle offset height can be set to an accuracy of ± 0.1 mm (0.004 in) very quickly.” This fast, accurate, non-contact method results in no scratches to the material. The laser ensures waterjet cutting to high precision; necessary when producing close tolerance, multi-axis parts. Operators can quickly and easily cut precise parts, even when bevel cutting.