Laser, Waterjet, Plasma Cutting Systems

A yearend review of some of the current advances and application capabilities in each of these metal cutting technologies.

Posted: November 5, 2014

Flow International is a global technology-based manufacturer committed to world-class waterjet cutting and surface preparation solutions that offer dynamic business growth opportunities and increased profitability to customers.

Flow International Corporation, 23500 64th Avenue South, Kent, WA 98032, 253-850-3500, cnunan@flowcorp.com, www.flowwaterjet.com.

ASSEMBLE YOUR OWN WATERJET

Never before has a manufacturer offered a top-of-the-line system that they currently sell in kit form. WARDJet, Inc. (Tallmadge, OH) now announces the WARDKit Series of waterjets, where owners get the same quality, engineering and design of a virtually identical Emerald Series waterjet – from tank design and manufacturing down to the cutting head – in an easy-to-assemble kit for 40 percent off!

http://youtu.be/Q0_Xh2qcM1E

With this package, even the control software included is identical to all of company’s high-end systems. This same software is used to run the large format combination 5-axis waterjet and mill currently installed at an aerospace research facility in the United Kingdom. The WARDKit is manufactured entirely in America and available in 5 ft x 5 ft, 5 ft x 10 ft, and 2 ft x 2 ft sizes.

Customers start by attending the commitment-free training course, then return home with the confidence and knowledge they need to assemble a waterjet themselves. The price of a WARDKit includes everything necessary to start waterjet cutting, such as the tank, cutting head, grates, intensifier pump, and human machine interface. The package even includes access to the company’s renowned technical support. Upgrades and options on pump horsepower, controller style, and abrasive delivery system are also available to allow for perfect configuration.

Prices for the WARDKit begin as low as $65,000. Financing is available for those who qualify for as little as $67 per business day! Adding a waterjet to the shop has never been easier, more affordable, or fun!

The company also offers the Emerald 0606 (2 ft x 2 ft) and the Emerald 0612 (2 ft x 4 ft) to the existing Emerald Series Line of low cost, American made waterjets. The Emerald 0606 offers a cutting envelope of 2 ft by 2 ft and 12 in of Z-travel and is uniquely designed with ballscrew drives and a cantilever-style arm. This short-travel, cantilever architecture effectively balances the reduced machine footprint and number of moving parts of the Emerald 0606, while maximizing cutting envelope and maintaining overall stiffness.

The Emerald 0612 offers double the cutting envelope at 2 ft by 4 ft. The cantilever-style arm is ballscrew driven, the tank is beefed up for extra support, and the overall footprint is small. The Emerald 0612 offers the advantage of indexing sheets of unlimited length from front to back – standard 4 ft by 8 ft sheets of material up to 2 in thick can be cut with greater convenience.

The company has also designed two high-speed, high-production, American-made waterjets: the J-Series and L-Series. These reliable waterjet cutting systems are paired with innovative solutions for material handling and automation to provide a competitive edge in the waterjet industry.

http://youtu.be/K55wtLZqoNg

The J-Series can accommodate the addition of material handling solutions such as loading/off-loading tables, as well as optical sensors to control chain feed tables or pinch feed rollers. The modular design of the J-Series waterjet makes it possible for small design changes to turn a standard waterjet system into a machine designed specifically for your application.

The L-Series is the fastest cutting waterjet offered by WARDJet. It uses a linear motion drive system, renowned for its excellent accuracies, placement repeatability, and reliability allowing customers to cut at incredible speeds of 7,000 ipm with an acceleration and deceleration rate of 1 m/ s2. The frame of the L-Series is made of thick-walled steel tubing that can accommodate multiple 5-axis cutting heads.

http://youtu.be/gaZPPw20l6Q

WARDJet, Inc. 180 South Avenue, PO Box 517, Tallmadge, OH 44278, 330-677-9100, sales@wardjet.com, www.wardkit.com.

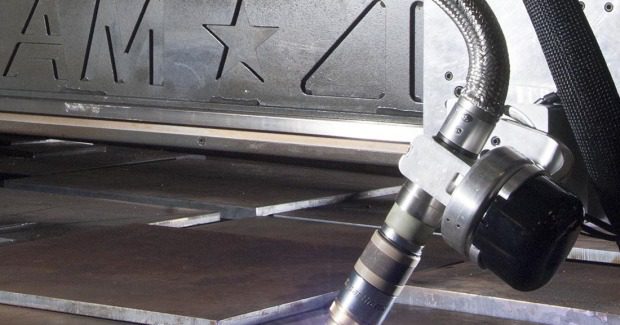

WATERJET CUTTING FOR FARM MACHINE SHOPS

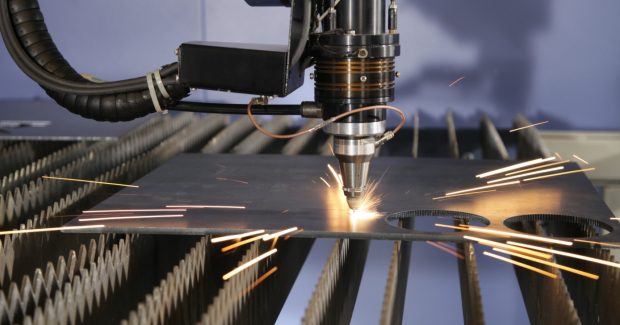

Waterjet cutting has numerous advantages over other cutting methods. Waterjet cuts virtually any material and thickness without creating a heat-affected zone (HAZ), case hardening or recast, or molecular change of the material. Unlike plasma, waterjet cuts without creating any noxious fumes.

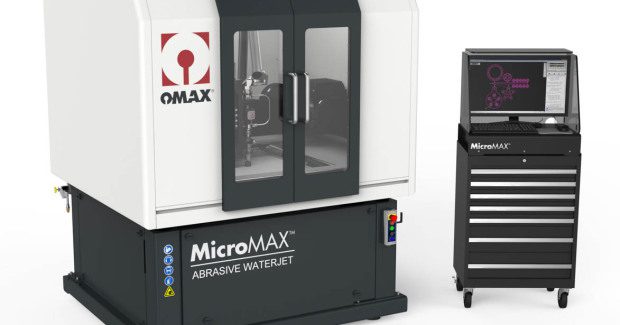

Jet Edge, Inc. (St. Michael, MN) now offers the FARM-JET® waterjet cutting system, a 55,000 psi waterjet cutting system designed and priced especially for the farm machine shop. An industry first, FARM-JET brings the power and versatility of ultra-high pressure waterjet cutting technology to farm machine shops for the price of a new fully loaded 1 ton 4X4 pickup truck, without requiring special electrical service.

http://youtu.be/UOGJeI_WYWA

The FARM-JET system includes a 40 in x 40 in (1 m x 1 m) waterjet cutting table and an Eco-Jet PTO direct drive waterjet pump (see below) that utilizes a tractor’s PTO shaft to produce 1 gpm of 55,000 psi water. The system includes one abrasivejet cutting head and a motorized Z-axis with 5 in (130 mm) of travel. The FARM-JET system is controlled with a Windows® PC (sold separately) and uses a FlashCut Pro-Series Stepper Controller and FlashCut CNC software. It also includes IGEMS path generation software and a hand-held controller pendant for operator convenience.

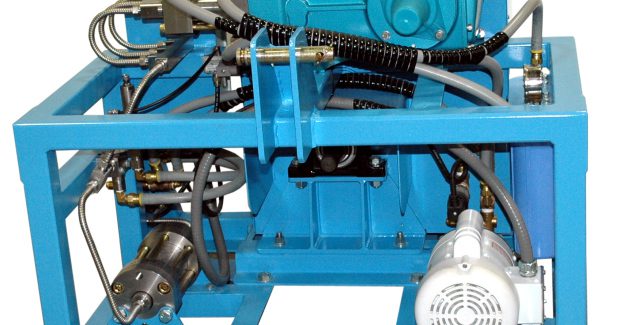

The Eco-Jet PTO ultra-high pressure waterjet pump, an affordably priced direct-drive style waterjet pump designed especially for use in rural machine shops or in areas with limited power, is an industry-first that utilizes a tractor PTO shaft to produce ultra-high pressure (UHP) water for precision cutting, cleaning and surface preparation applications. It runs a .015 in waterjet orifice and can power most manufacturers’ waterjet cutting systems and waterjet tools. Unlike traditional industrial waterjet pumps, the Eco-Jet PTO requires only a standard 120 V 60 Hz power source, making it practical for farm machine shops and shops with a limited power supply. The Eco-Jet PTO pump is made in the U.S.

With the Eco-Jet PTO is available for 540 RPM and 1000 RPM PTO shafts and Category 1 and 2 three point hitches (tractor sold separately). In addition to a 120 V 60 Hz power source, it also requires a fresh water source. The FARM-JET system requires a 115V 60 Hz or 230V 50 Hz power source, fresh water source and a suitable tractor.

“This is the first waterjet cutting system that is designed and priced for the farm shop,” noted Jude Lague, the president of Jet Edge. “Until now, if you wanted a waterjet, it meant a six-figure investment and access to 460 volt power. Now you can own a waterjet for the price of a new truck and run it off standard household electric and your tractor PTO. With a waterjet system, you can create a nice source of additional revenue and, if you need a part fast, you can cut it in minutes instead of waiting for days or weeks to have it fabricated and shipped. You also can have some fun with it cutting custom tile inlays for your house or racecar parts for your dirt track team.”

The company also offers the BOSS-CUTTER water jet cutting system, an economically priced water jet designed especially for small shops that features a 40 in x 40 in (1 m x 1m) work envelope. This system includes one abrasivejet cutting head and a motorized Z-axis with 5 in (513 mm) of travel that is controlled with a Windows PC (sold separately) and uses a FlashCut Pro-Series Stepper Controller and FlashCut CNC software. It also includes IGEMS path generation software and a hand-held controller pendant for operator convenience.

BOSS-CUTTER is powered by a Jet Edge waterjet pump. The company offers the widest range of waterjet pumps in the industry, including 30 hp to 280 hp hydraulic intensifier pumps in 36 ksi, 60 ksi and 90 ksi models, electric and diesel, and direct drive pumps. In fact, Jet Edge and Alliance Automation, LLC (Grand Blanc, MI) announced that Alliance Automation, a leading designer and manufacturer of custom industrial automation and robotic systems, is powering its latest generation of robotic waterjet trimming cells with Jet Edge intensifier pumps.

Featuring dual wall-mounted Motoman HP20D robots and Jet Edge 60 ksi (4100 bar) iP60-50 waterjet intensifier pumps, Alliance Automation’s new 6-axis robotic waterjet trimming cell leads the industry in precision and dependability, with Motoman’s ±0.06 mm repeatability and Jet Edge’s reliable tie-rod intensifier design. The cell’s sturdy, compact frame design allows stability to both the tool and robots to ensure consistent tight part tolerances.