Rethinking Your Parts: Combining for a Competitive Advantage

You may discover a whole new profit method in a combination processing machine that can produce all of the geometries you need at the same cost, regardless of the number of parts required.

Posted: November 4, 2014

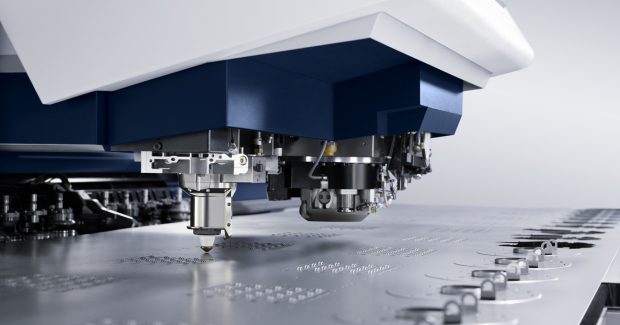

Have you ever thought, “Do I need a laser cutting machine to competitively quote this part?” Or perhaps, “Do I need a punching machine to process these forms?” A combination punching and laser cutting machine allows fabricators to process metals with both of these technologies in materials up to 0.312 in thick, all with one machine tool. This also enables manufacturers to choose the technology best suited for the application and to produce the part in the most cost-effective way.

COMMON MISCONCEPTIONS

Some shops think processing with combination machine technology will cost more per part to manufacture. Their concern is that only one technology can be used at a time and that the initial cost of the equipment can be equal to purchasing a standalone punch machine and a standalone laser machine. These points are true because the punch head and laser head both stay stationary while the material moves into position, so when the laser is in use, the punch is idle. Likewise, when the punching head moves, the laser is inactive. However, the technology grants additional flexibility when producing parts that can make processing a part on a combination machine far more economical than it would be with two separate machines.

With two separate machines, fabricators also often believe they can produce twice as many parts. Their logic is that for parts where both technologies are needed, operators can simply move the part from one machine to the other. While this is true, there are also limitations to this method. First, the additional machine consumes valuable floor space. Second, when moving a part between two machines, fixtures are essential for maintaining dimensional accuracies. Finally, additional manpower is needed to fully fabricate the parts using two machines. Other hidden costs may also factor in, such as the overall time it takes to produce the part.

TODAY’S MANUFACTURING ENVIRONMENT

Continuous improvement practices have taught us the advantages of producing parts in smaller lot sizes. In addition, value stream mapping shows the cost savings achieved by eliminating secondary handling of parts, or manual movement to multiple machines. Combination technology is not ideal for every application, but it has a bigger presence on the manufacturing floor than many people realize. Consider the following examples to better understand where combination technology excels.

Sample One

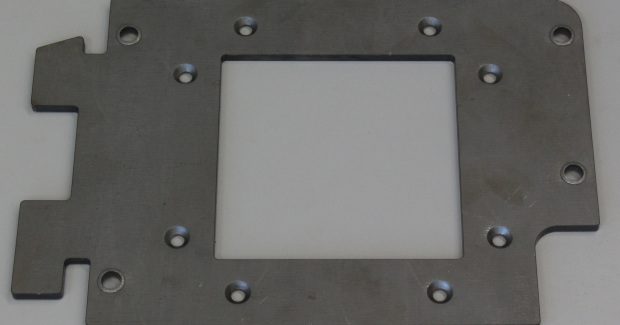

Consider an adapter plate (see Figure 1) fabricated from 0.187 in thick cold rolled steel. This part requires counter bore holes, tapped holes, countersinks, shear tabs, and a laser cut quality edge that is free of burrs. An adapter plate such as this could take up to four different machines to process and would require six different handlings during the processing of the part.

First, a laser cutting machine would be used to cut the internal and external geometries. Although the laser could also be used to produce the holes, this may affect the hardness of the part for the addition downstream operations needed for completion. If this was a concern, a drill press would be needed to create, counter bore, and countersink the holes. This would require a special fixture so the machine could accurately locate the geometries in the designated dimensions on the part.

The adapter plate would then be taken to a tapping machine. After the threads were produced, the part would move to a punch press. This would create the shear tab which is used to locate the adaptor plate to its mating part. The quick summary chart below shows what would be required to produce the part, depending on the equipment chosen. The results may be surprising.

| Adaptor plate | Through Time | WIP | Travel Distance | Setup |

| Laser | 75 minutes | 10 pieces | 430 feet | 65 minutes |

| Punch | 47 minutes | 10 pieces | 120 feet | 35 minutes |

| Combination | 29 minutes | 10 pieces | 70 feet | 20 minutes |

This sample part was fairly complex and required multiple processing steps. Let’s consider two other examples where a combination processing machine can prove more time and cost effective.

Sample Two

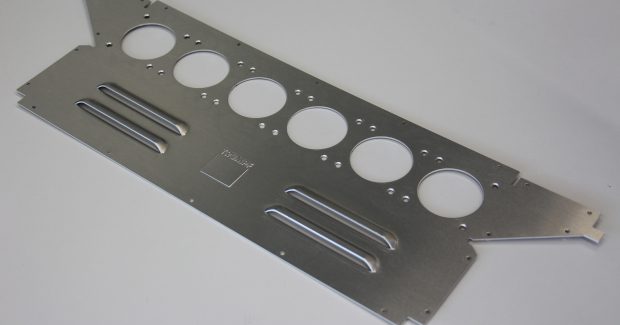

This aluminum part (see Figure 2) can be produced completely on a punch machine, including the formed louvers, countersinks, and even the cosmetic edge. However, the problem here is that by using a punching machine to create the contours and corners, the tool hit mark will be visible. By using a combination machine to laser cut the outside contour of this part, the fabricator would eliminate this issue and have a perfect, mark-free part directly from the machine.

Sample Three

Our third sample is a part with flanges and return bends – all at different heights – and locked together with the stitch cut (see Figure 3). A standalone punch machine is able to produce flanges up to one inch high, and with specialized tooling, can also generate the complex internal and external geometries. Investment in this type of tooling can be costly and part specific. If the job is for a minimal amount of parts, most of the profit will be spent on tooling.

The laser cutting component of a combination processing machine enables manufacturers to produce the geometries needed at the same cost regardless of the number of parts required. You might ask, “Why not laser cut all my geometries?” The answer is speed. It is still faster and more cost effective to process holes or geometries using the punching portion of the combination machine.

The next time you calculate the cost of producing a part, start with these considerations:

- How many parts do I have to produce?

- How many secondary operations do I have to incorporate to produce the part?

- What is my total travel path and time needed to complete the specified lot size?

- Do I need to produce extra parts to eliminate mistakes, scrap, and rework?

As you consider the needs of your shop and how combination processing might fit, you may just find a whole new profit method.