PCD Chipbreaker for Machining Aluminum

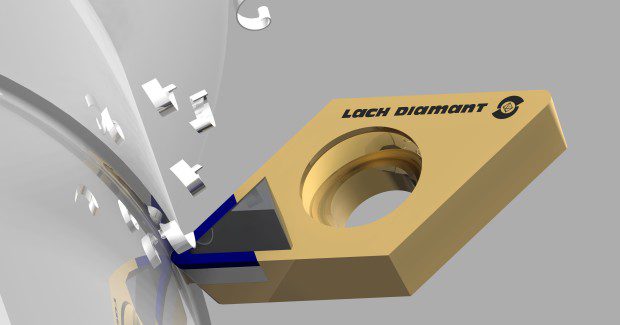

The Type IS chipbreaker from Lach Diamond is ideal for rough machining thick-walled, solid components and for interrupted cuts.

Posted: December 23, 2014

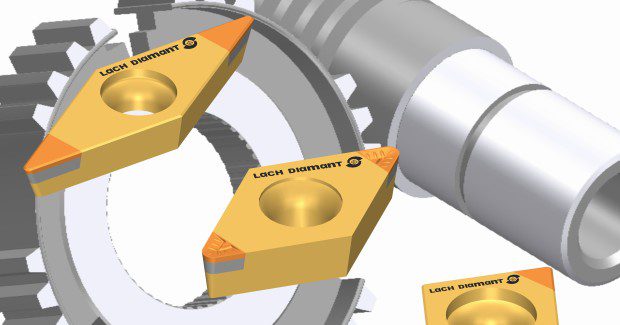

Lach Diamond, Inc. (Grand Rapids, MI) was a pioneer in placing a three-dimensional guide step as a chipbreaker into the diamond layer of a PCD insert. From this the company developed several variations for their chipbreaker program for the machining of nonferrous metals, especially for aluminum. This became a key element in series and mass manufacturing.

Their newly patented chipbreaker Type IS (U.S. Patent 6.315.502) has an active chipbreaker and stable cutting edge that was developed mainly for the rough machining of thick-walled, solid components with a SI content below 7 percent. It is also suited for interrupted cuts. With cutting speeds from 800 m/min to 2,500 m/min and feed rates from 0.1 mm/r to 0.3 mm/r depth of cut, up to the maximum utilization of the cutting width from to 3 mm to 5 mm are possible. For thin walled, unstable components the identically constructed chipbreaker, the chipbreaker CO, is available.

Many shops are also trying to determine whether to continue CBN grinding or to begin CBN turning. Lach Diamond first introduced CBN tools for the turning of sprayed-on materials at the Hanover Fair/Germany in 1974. Up to that point, no alternative method existed for the necessary grinding process. In next to no time, hours of grinding time were reduced to minutes of turning time. These CBN cutting tools (under the trade name of dreborid®-B) have opened up a broad spectrum of all-around application possibilities for the machining of hardened materials, such as the turning of high-alloyed steels over 58 HRc and cast iron components also with interrupted cut.

The special tooling of Lach Diamond, as well as that of manufacturers of CBN/PCD cutting tools and diamond and CBN grinding wheels, requires expert consultation in the question of application between grinding and turning for each respective case and how it can be solved most efficiently.

Lach Diamond, Inc., 4350 Airwest Drive Southeast, Grand Rapids, MI 49512, 616-698-0101

www.lach-diamond.com.