Cutting Edge Technology for Cutting Tool Production

These advanced laser cutting and inspection systems enable cutting tool manufacturers to achieve results that were formerly unattainable.

Posted: December 8, 2014

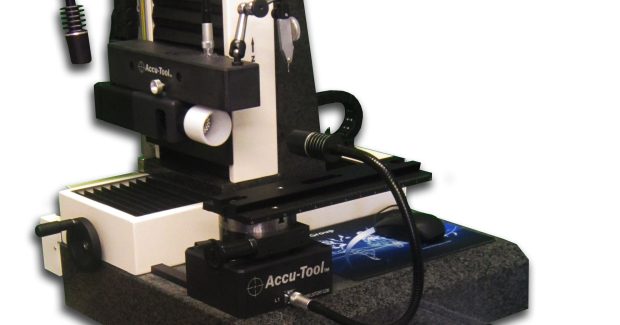

The future of cutting tool manufacturing is being revolutionized with the most advanced technology on the market. Laser Measuring Technologies, LLC (Caro, MI), a division of The LMT Group, starts with their completely revamped Accu-Tool with new abilities that are specifically designed for the cutting tool industry, making production quicker, easier and more accurate than ever before.

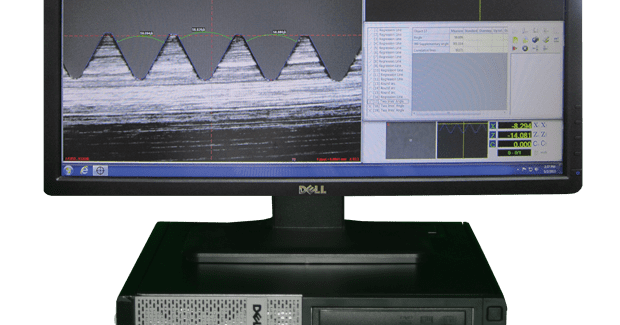

The Accu-tool offers a simple automatic screen calibration process and magnification capabilities from 20X to 470X zoom that can meet any shop’s cutting tool measuring needs. The specially designed software works seamlessly with the Windows operating system supplied with each machine. The system uses high precision guide rails that are mounted directly to the X-axis and Z-axis for optimal thermal stability due to the solid granite base.

This advanced cutting tool measuring software system allows for automatic measuring, auto edge detection and complex geometry inspection. It can measure step length diameters, drill clearance angles, cylindrical margins, rake margin and more.

Specifications include:

- Operating system: Windows 7, 32 or 64 bit (software pre-loaded)

- Monitor: 23 Flat panel wide screen (minimum)

- Screen Resolution 1920 x 1080

- Language: English

- Output to: CAD, Excel and Word

- Input: CAD for .dxf file overlay

- Focus Distance: 3.23 in – 6.89 in

- View Field (Diagonal Length): .05 in – .3 in to .1 in – .6 in

- Magnification: 44X – 280X to 22X – 140X

- Camera: 1.3 megapixel USB CCD color camera

- Computer: Desktop (supplied)

- Resolution (Pixel): 1.3M

- Output: USB2.0

- Accuracy: 0.001mm / .00004 in

- Repeat-ability: 0.002 / .00008 in

- Warranty: One year

- Light: Adjustable variable intensity LED work lights

- Electrical Requirements: 110 V 2.5 A, 220 Optional

This is cutting tool measuring made simple, accurate, fast, and most of all affordable!

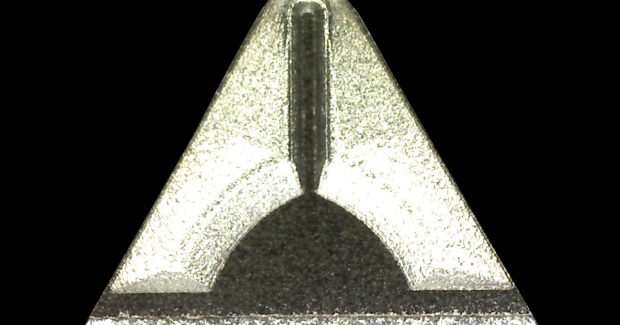

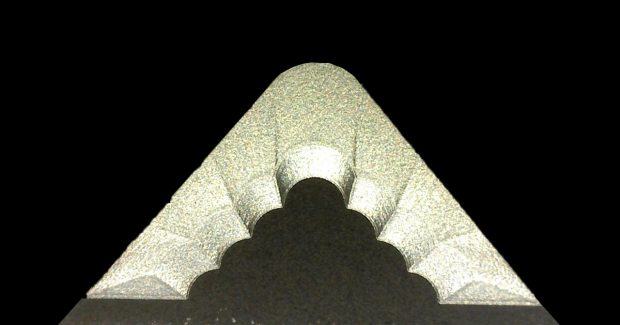

But there’s more. The company now offers advanced laser technology with the new 3D COBALT®, an 18 W fiber laser for cutting and shaping a variety of materials that provides surface finishes for extremely difficult manufacturing processes. The system operates at 1,064 nm and is accurate to 2,500 nm with a machining range of 40 mm by 40 mm, meaning the cutting tool industry is now able to achieve results that were formerly unattainable.

The 3D Cobalt is a more space efficient, affordable version of our original micro-machining laser system for cold micro-machining of 3D forms, 2D shapes and many other materials including but not limited to PCD, CVD-D, CBN, tungsten carbide, rubies, natural and man-made diamonds and many other exotic materials.

To get all of this production running in the shortest amount of time, the innovative 3D digital scan head offers the user a faster and easier set up due to the Z-axis scanner and 3-axis control. Users can now program complex shapes in the most time efficient manner. This new digital scan head has a sleek and industrial design based off of the latest cutting-edge technology and can be provided inside an enclosure and also can be mounted outside for in process marking.

LMT Group, 1101 W. Sanilac Road, Caro, MI 48723, 866-799-0199, Fax: 989-673-1655, sales@Imtgrp.com, www.lmtgrp.com.