Four Major Trends To Follow

State of the Industry: Manufacturing has always been the backbone of the U.S. economy and now, with lower cost and more abundant energy sources at our disposal, the future looks brighter than ever as new technologies come to market to address several pervasive influences in our industry.

Posted: December 22, 2014

Relative to the last couple of years, business in 2014 has been growing and experiencing a nice upward trend, especially over the past few months. The oil and gas market remains resilient, but it has cooled off in some geographic areas. Shipbuilding, particularly marine defense, is another active market, as is railcar. The automotive industry is healthy and operating at a high level, but doesn’t show signs of growing at least not at the level in past years. Heavy equipment (especially mining) continues to be challenged but may have bottomed out. Ag equipment is definitely entering a trough in their cycle.

There is significant opportunity in the welding industry to provide solutions that improve weld quality, increase productivity and reduce costs, regardless of the application. Even more so because the skilled welder workforce is aging, with fewer and often less proficient welders entering the industry, meaning there is a greater need for welding products with intuitive, simple-to-use interfaces. New technologies, such as reality-based training systems, are also helping to address training needs and to build a stronger workforce.

FOUR TRENDS TO WATCH

Overall, there are four key trends to keep your eyes on that are developing and will continue into 2015:

Changing Materials

One trend is the growing use of thinner, lighter, stronger and more corrosion resistant materials. In response to the CAFE standards, the automotive industry is moving toward the thinner and lighter materials, such as aluminum and higher strength galvanized steel, to reduce vehicle weight. Likewise, tougher and more corrosion resistant materials are being used for applications (e.g. offshore, oil and gas) for service in more extreme environments. These changes in material choices affect the welding technology that shops need and welding equipment manufacturers must respond with technology that helps them maintain or increase their production times and generate the quality they need.

Information Management Systems

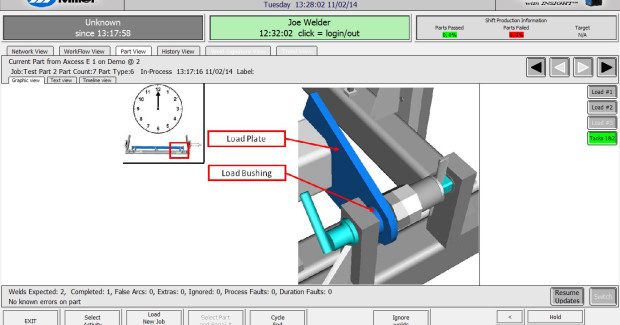

With the ongoing adoption of lean manufacturing methods and an increasing need for traceability and documentation of processes, another trend is the increasing implementation of information management systems in welding operations. These systems are designed to offer process monitoring and control, and can help companies understand the true cost of the welding operation. Welding equipment manufacturers must provide tools like these to help shops drive continuous improvement.

Higher Productivity

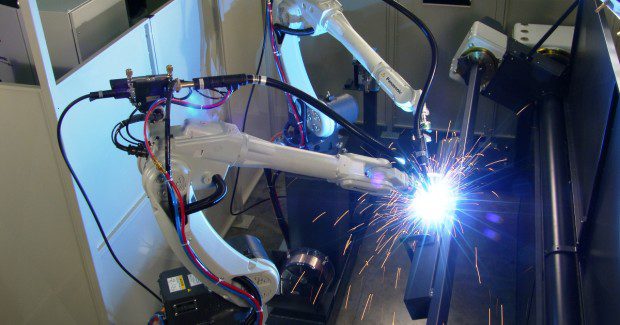

A third trend is the implementation of solutions to increase productivity even as companies are faced with a lack of skilled labor. Automation use is on the rise, as are activities designed to eliminate inefficiencies in the welding operation. Many companies are seeking to do more with their existing capital as well. The goal is to implement technologies (or find better uses for existing technologies) to help companies do their work better, faster, and at less cost than ever before.

Cleaner, Safer Environments

The last trend sees more factories working to establish cleaner and safer welding environments. This is happening not only from a desire to meet future environmental regulations set forth by OSHA and the American Conference of Governmental Industrial Hygienists (ACGIH), but also to create a better environment for employees and to aid in recruiting and retaining skilled welders. Welding industry suppliers must constantly work on developing new filler metal formulations that lower undesirable fumes from the source (the wire). Welding equipment manufacturers must offer innovative source capture technologies that feature improved capture distance to help shops with their endeavor. On top of all of this, individual worker protection continues to get better as technologies improve.

ISSUES AT HAND

I personally believe lack of skilled labor is one of the most critical issues pressing our industry. There simply aren’t enough new welders to meet demands due to growth in manufacturing, on-shoring, the aging welder workforce, etc. Workforce development efforts must target the education of potential industry entrants on the importance of welding to our economy and the many great career opportunities that exist. Some of the best paying engineering jobs are welding engineers, yet they are a small fraction of the total engineers who graduate each year. How many people actually realize this important fact?

Driving an interest in this industry and offering the appropriate training is absolutely essential. Our company is very much committed helping impact this need. As an industry, it’s imperative that we better educate future potential entrants on the great opportunities inside this industry so they can grow to serve as the next wave of engineers, welders, welding supervisors, etc. We are competing with other industries for the brightest minds to drive future technology, so we must be committed to help educate and train these future employees and to help our customers and channel partners succeed in finding and training the best people.

Tools like our LiveArc system, Miller Masters (channel training program), and supporting technical colleges can all make a difference. In many cases, increasing welding automation is another way to address the lack of skilled labor. We continue to increase our presence in the robotic welding and automation space while working with integrators and our channel to bring technical solutions to our mutual customers.

Another critical issue is the current drop in prices in the energy market, which could have interesting short term and long term impacts on our economy and business opportunities. This is a complicated matter, but there is no doubt that cheaper energy will have many positive impacts, even to the extent of making the U.S. a more competitive place for manufacturing things. If you are an energy producer or involved in that chain of activities, energy prices are creating some short term uncertainties. But in the long term, access to low cost, clean energy sources and the right energy polices will help our country retain a competitive edge in the global economy.

Relative to the energy market, we have been investing in the Houston market and recently opened a new technical center that has been designed and staffed with top people to demonstrate our technical and product capabilities. Training is a key component to this effort and we welcome our channel partners and customers to come see us with their toughest welding needs. Along with showcasing our capabilities, this center is equipped with the latest technology, ranging from welding power sources to subarc systems to automation capabilities.

EXCITING TIMES

It’s an exciting time to be in this business. Manufacturing has always been the backbone of the U.S. economy and now, with lower cost and more abundant energy sources at our disposal, the future definitely looks bright. Plus there are a lot of new technologies coming to the market that address many of the key pervasive trends: the need for lighter, thinner, stronger, and corrosive resistant materials; implementing lean manufacturing methods as it relates to welding; increased productivity; and improved worker safety, not to mention growing the workforce.

We are excited to be able to provide the technology that companies in this market need to get the job done and to continue to drive continuous improvement in their operations. We are poised for some exciting times ahead and I’m happy that we can be a part of our channel and customers’ on-going success in the marketplace. The industries that we serve as a collective group will be the engines that drive our economy forward.