Broach Tooling for Machining Centers

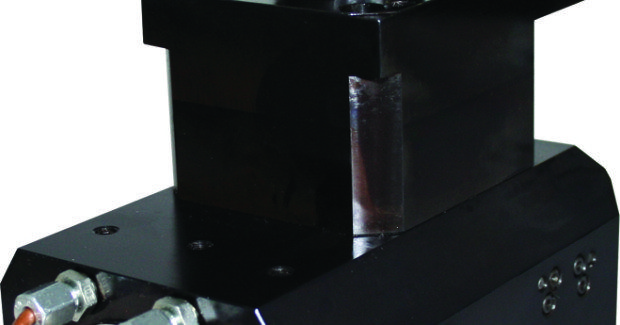

The gearing of the LinA push-type unit from BENZ converts the rotational movement of the drive into a linear movement of the chisel to create geometric forms up to 35 mm long on machining centers with the axial push-type unit.

Posted: December 22, 2014

BENZ Incorporated (Charlotte, NC) has introduced its LinTec series of broaching tools and the Solidfix® Quick-Change system that is engineered at BENZ GmbH Werkzeugsysteme (Kinzigtal, Germany) and sold and serviced in the U.S. and Canada from its U.S. headquarters in Charlotte.

Previously, conventional push-slotting of forms on machining centers was only possible by moving the rotational axis. All machining processes had to be programmed via the machine control in advance. Now the success of the driven push-type unit LinA for CNC lathes has been transferred to a newly developed unit for machining centers. The gearing of the push-type unit converts the rotational movement of the drive into a linear movement of the chisel. With the new LinA, operators are able to create geometric forms up to a length of 35 mm on machining centers with the axial push-type unit.

The product range for CNC lathes has also been expanded in keeping with the demands of the market. The LinA long stroke allows the push slotting of deeper forms compared to the standard version LinA. This is made possible by a longer working stroke of 51 mm compared to the standard version’s 32 mm.

These new products feature driven live tools with Solidfix® interface for swiss tooling. Swiss tooling applications are usually characterized by very small parts, which are produced in high quantities in multi-shift operation. Down time costs money, so manufacturers are looking for the quickest and easiest way to make tool changes.

Tools have been developed with the Solidfix integrated modular quick-change system in size 1. Using this system, only the adapter has to be changed while the tool holder stays on the turret. Tools can be preset outside the machine, saving the user additional time. Quick tool changes are even possible with very little room in the machine at the tool holder. Factors such as tool diversity, set-up time and precision are important in production and this modular quick-change system addresses each of these needs.

More than 30 years of experience in developing and producing CNC machine tool accessories make BENZ one of the leading system partners in the metalworking and composites industries. The sophisticated product portfolio reflects high quality and innovative precision engineering, including static and live tools, and exchangeable units such as angle heads, multi spindle heads, modular quick-change systems and large drilling heads, as well as 2-axis CNC-NC heads.

A combination of modern management and advanced, innovative engineering has transformed this traditional tooling company with over 250 employees into an innovative, growing enterprise.

Benz Incorporated, 8325-J Arrowridge Boulevard, Charlotte, NC 28273, 704-529-5300, Fax: 704-529-5009, mail@benz-inc.com, www.benz-inc.com.