Clamping for Difficult Machining Applications

These clamping systems from Lexair are ideal upgrades for manual lathes, rotary tables and indexers that require higher grip force for difficult applications.

Posted: December 23, 2014

The Systec front-actuated pneumatically powered jaw chuck from Lexair, Inc. (Lexington, KY) is an ideal automation upgrade for manual lathes, as well as rotary tables and indexers that require higher grip force for difficult applications. The self-contained air-open/air-close chucks are available in five sizes from approximately 5 in to 12 in.

This drawtube-free design offers through-hole capacity up to 4.52 in, with more than 18,000 ft-lb grip force at 1,000 rpm for the largest size. Systec master-jaw/top-jaw chucks are available with inch or metric serrations in all sizes. Most sizes are available in two, three or four-jaw configurations, and the four-jaw design can be used as a two-jaw. Using an adapter plate, the chuck will fit A5 to A11 spindle faces.

The chuck’s non-rotating air manifold uses Teflon seals that are virtually maintenance free and help increase the grip force. The chuck operates with only 90 psi air pressure. Internal safety valves prevent loss of air pressure and gripping force. The chuck itself is extremely rigid and durable, with a precision-ground body, fully hardened to 62 HRc. It comes standard with a pair of hoses, mounting bolts and T-nuts. Accessories include spindle adapters, soft and hard-top jaws, grease gun, a manual directional-control valve and a dual foot-operated valve.

Lexair also offers the OML MC Modular Workholding System that uses fixed and movable vise jaws and patented self-locking CLAK parallels to achieve multiple clamping solutions and increased part accuracy with less set up time. Unique features on the MC vise include snap-in, self-locking middle-jaw CLAK parallels that are held in place when the vise is opened in the vertical position, making it ideal for use on tombstones.

The CLAK system allows for quick-change of parallels, angular parallels, soft jaws and “V” jaws, making part changeovers and size changes quick and easy. A unique tapered-jaw design pulls the workpiece down against the parallels as the vise is closed, eliminating the need to hammer the part down. The MC vise is designed for quick changeovers with a moveable clamping jaw that can be lifted from the base, shuttled to the next position and lowered into place for a different size workpiece. Held in place with a toggle locking mechanism, the moveable jaw unlocks from the base with a flip of the wrist.

By relocating the clamp jaw close to the workpiece, the length of the clamp screw can be kept short, minimizing jaw distortion under high force. The clamp screw can also be replaced with a hydraulic cylinder for automated operation. The MC vise accommodates jaws with rolls, GRIP jaws, aluminum jaws, middle jaws, jaws with grippers UGE, Plus 3D jaws and floating side-ways for raw workpieces. Various jaw adapters, including one for Kurt jaws, allow the use of legacy vise accessories. Adding to their versatility, the vises are easily transported between machine tools. The 6 in by 8 in (150 mm by 200 mm) base with a simple clamping system weighs only 55 lb (25 kg).

The base length determines the vise’s clamping capacity and the jaws can be used with any base configuration, providing a flexible workholding solution with minimum investment. Bases are 6 in wide (150 mm) and available in 8 in (200 mm), 10 in (250 mm), and 12 in (300 mm) lengths. An 8 in (200 mm) by 12 in (300 mm) base is also available, as well as two extended length MC-XL models, with lengths of 21.5 in (545 mm) and 26 in (655 mm).

All components are constructed from oversize steel profiles and are case hardened and precision ground to ensure exceptional flatness and durability. Wear parts are specially treated for a surface hardness of 50/60 HRC, and all non-ground surfaces are burnished to protect against corrosion.

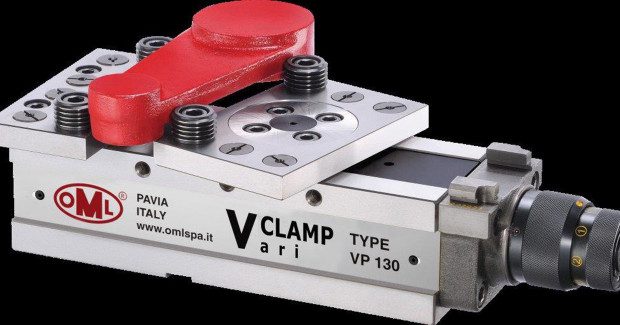

The OML VariClamp modular clamping system uses a floating mechanism of fixed and moveable jaws and a wide variety of gripper forms to provide custom clamping of irregular-shaped workpieces, including round, curved, elliptical, rectangular, stepped and slanted parts. VariClamp vises can be configured with any combination of fixed or swiveling jaws, and various styles and heights of grippers, including smooth, serrated, soft, high, and with or without stops. Grippers are added via holes placed throughout the vise to conform to the part shape, and holes are capped and covered when not in use.

A swivel mechanism incorporated into the moveable jaw allows for easy clamping of slanted and rough-surfaced parts. The super-low profiles of the fixed and moveable jaws also allow clamping of thin workpieces for heavy duty cutting and precision processing. VariClamp vises are available with an optional mechanical clamping force multiplier/limiter that sets the grip force from one to four tons. Operators can easily set and maintain the grip force to prevent part distortion and establish accurate, repeatable clamp force with a simple, one-handed turn.

Available in three sizes (100 mm, 130 mm and 160 mm), VariClamp’s wide opening and compact length make it particularly suitable for use with machining centers. An expanding chip cover prevents chips from falling into the lead-screw and inside the vise. These rugged vises are made of GGG-60 ductile iron with a tensile strength of 80,000 psi (60 kg/sq mm). The vise bed is flame hardened to HRC 45 for long-term accuracy; jaws are hardened and ground to HRC 52~55.

Lexair also offers the Breuning IRCO ecoPROFI that delivers automatic, multi-size barfeeding in an economical, small-footprint package that is ideally suited for job shops and others looking to increase flexibility, productivity and efficiency. It is capable of handling barstocks from 0.2 in to 2 in (5 mm to 50 mm) with a unique multi-channel “Gatlin-Gun” style magazine that allows one-button channel changes in seconds for small-batch flexibility. A three-channel magazine is standard, and is easily expandable to a six-channel magazine.

The ecoPROFI is available in standard lengths of 10 ft, 13 ft, and 20 ft (3,000 mm, 4,000 mm, and 6,000 mm), with custom models available for bars up to 33 ft (10,000 mm) long and 5.1 in (130 mm) diameter barstock. Lexair provides sales, support and repair services for IRCO high-performance German-made automated systems that serve high-volume, cylindrical and shaped-part makers in the heavy equipment, automotive and aerospace industries, among others.

The ecoPROFI is compatible with all standard and Swiss-style lathes, as well as machining centers and rotary transfer machines. A specially designed loading flap allows for reloading of bars without machine stop. Hydrodynamic bar guiding circulates oil through the guide channel continuously to produce a damping effect and stabilize the bar in the channel for optimum concentricity and reduced load on the machine spindle. Hydrodynamic damping bridges diameter increments and ensures low-friction, nearly vibration-free guiding of the bar.

Lexair Inc., 2025 Mercer Road, Lexington, KY 40511-1018, 859-255-5001, Fax: 859-255-6656, www.lexairinc.com.