Tool Grinder Handles Complex Cutting Tools

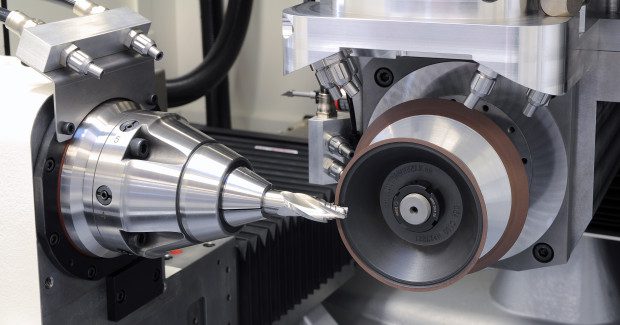

The flexible, high-accuracy U-Grind 5-axis CNC tool grinder from Strausak is ideal for small batch production, regrinding, and high-precision tool grinding.

Posted: December 23, 2014

Strausak AG (Lohn-Ammannsegg, Switzerland) provides products of excellent thermal stability to facilitate consistent and accurate small batch production and regrinding, as well as a unique design for high-precision tool grinding. Recently, Hank Ecker (previously the regional sales manager at Rollomatic Inc.) assumed the role of president for Strausak Inc. (Mundelein, IL) and is now responsible for North American operations.

The company is now offering their new U-Grind, a flexible, high-accuracy 5-axis CNC tool grinder that includes:

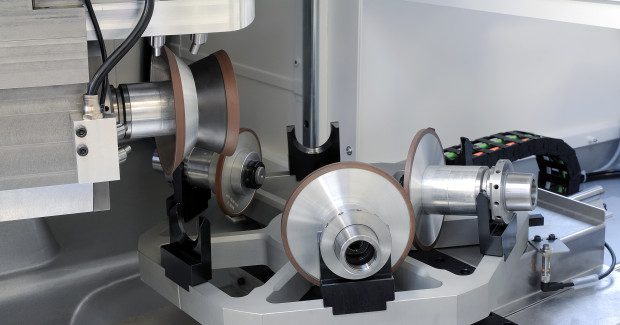

- Standard automatic wheel changer, direct-drive grinding spindle 12 kW (17 hp) and optional auto loader.

- Automatic quick-change system for collet change and for changing basic tool holder ISO-50 taper.

- Optional touch probe for grinding wheels qualification.

- NUM Fleximum control and the latest generation of NUMROTOplus tool grinding software.

- Software available for all types of cutting tools, including complex step/form tools, hobs, burs, shape cutters, T-slot cutters, high performance endmills and drills, routers, form tools, porting tools and more.

- Authorized drill point grinding for well-known manufacturers, including K-land grinding.

- 3D tool simulation, machine animation and collision checking.

- Digitizing of existing cutting edges for regrinding or grinding pre-fluted tools.

Strausak Inc., 1295 Armour Boulevard, Mundelein, IL 60060, 866-713-6398, solutions@strausakusa.com, www.strausakusa.com.