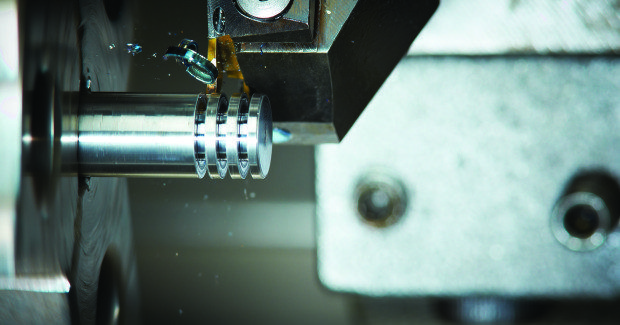

Groove and Part-Off Tools with Narrow Cutting Edges

The X4 multi-edge system from Seco Tools is great for external grooving and parting-off operations involving small parts, slim bars and tubes made from a wide variety of common materials.

Posted: January 23, 2015

Seco Tools, LLC (Troy, MI) offers the X4 grooving and parting-off system that is perfect for small-parts manufacturers and standard grooving in the industry. The X4 multi-edge system meets industry demands for grooving and parting-off tools with narrow cutting edges. Most recently, the company added smaller shanks to the short-reach system so that it can accommodate an even broader range of applications such as Swiss parts.

The X4 consists of indexable tangential inserts with three-dimensional chipbreakers and a highly stable clamp design. These strong, dependable system components achieve high accuracy, repeatability, productivity and surface quality in external grooving and parting-off operations involving small parts, slim bars and tubes made from a wide variety of common materials.

The system’s MC chipbreaker inserts cover cutting-edge widths from 0.02 in (0.5 mm) to 0.12 in (3 mm) and cutting depths between 0.1 in (2.6 mm) and 0.26 in (6.5 mm). Maximum bar diameter for cut off varies from 0.2 in (5.2 mm) to 0.51 in (13 mm) in diameter, depending on insert width. Insert profiles are available in neutral and angled right-handed and left-handed versions. Included in the offering is the common inch Top Notch widths used in the industry.

Flat profiles with positive rakes, designated R and FG, are also available. Featuring a round profile, the R-style inserts for grooving and profiling have cutting edges with widths that range from 0.04 in (1 mm) to 0.12 in (3 mm). The FG-style inserts cover groove widths from 0.05 in (1.15 mm) and 0.1 in (2.65 mm) and can machine lock-ring grooves to DIN471, DIN472, SMS1581 and SMS1582 standards.

An upper clamp rigidly holds the inserts, and users can fasten and release the clamping screw from the top or bottom, which makes it easy to load the insert into the holder. X4 toolholders come in a wide variety of shank sizes, including .500 in, .625 in, .750 in and 1.00 in, as well as Seco-Capto C4, C5 and C6.

The newest .500 in and .625 in shanks with a compact toolholder head design bring the reliability and value of the X4 system to small sliding-headstock machines, where there is a need for smallholders with cutting edges of narrow widths. Particularly advantageous is the fact that one toolholder works for all X4 insert types, allowing for a reduction in tooling inventory.

All X4 toolholders, except for the toolholder head design for the 1212 shanks, incorporate Seco’s Jetstream Tooling Duo technology that has coolant outlets from both the clamp and underneath the insert to further enhance productivity, lengthen tool life and improve chip control. By delivering coolant from two outlets to optimum points in the cutting and heat zones, Jetstream Tooling Duo effectively directs coolant to the front and bottom of the insert’s cutting edge, which increases tool life and effectively breaks up chips for an overall higher part quality.

Seco Tools is a leading provider of metalcutting solutions for milling, turning, holemaking and toolholding. The company prides itself on building close relationships with customers to effectively understand and address their needs.

Seco Tools, LLC, 2805 Bellingham Drive, Troy, MI 48083, 248-528-5444, lseidl@secotools.com, www.secotools.com/us.