The Cloud: What It Is and Why You Should Care

This primer examines the competitive advantages your shop can gain and the pitfalls to be avoided.

Posted: January 11, 2015

Most job shops, contract manufacturers and metal service centers we meet would rather spend an afternoon at the dentist than watch somebody go through a 45-slide presentation about cloud technology. At the end of the day, nobody wants to hear about architecture and delivery models. They only want to know how it will help their business and make them more profitable. So in the interest of using your time well, here are the basics of Cloud software and why you should care in the first place.

WHAT EXACTLY IS THE CLOUD?

What specifically are people talking about when they try to promote Cloud-based services? Here’s a no-nonsense definition: Cloud Computing means receiving your solution as a service rather than a product that you have to manage. In short, there will be no hardware or servers “living” at your plant. The software you need is delivered via the Internet and all its capabilities are available to your entire team on whatever device they like to work on, no matter where they are. All managed by your software provider.

The upshot? You don’t have to worry about building or maintaining an IT infrastructure. You are simply signing up for a software subscription. All the applications you need are managed by a service provider and metered out to you.

Investments in Cloud technologies are expected to rise dramatically for a few simple reasons: Cloud services save time and money on implementation, cost less to own, and are constantly updated when technology changes. Or, to put it another way, Cloud providers take care of the technology details, keep you up to date, leaving you free to concentrate on what you and your team do best – metal fabrication.

All of these advantages are driving both big and small job shops to adopt Cloud technology that brings their teams together to find efficiencies and meet customer demands. Here are a few more ways that Cloud technology is delivering an edge for metalworkers:

ESTIMATING AND QUOTING

Estimating and quoting jobs are critical to your business. Cloud software provides the ability to create quotes and proposals in minutes, not hours, as well as create quotes from scratch and templates, copy and edit previous quotes, attach anything to a quote, and base your quotes on up-to-date labor rates and material prices. This can all be done in your home office or out in the field using mobile devices.

In short, Cloud solutions can tie your whole team and all their data together in the workflow so that your material, labor and production costs are reflected consistently in your quotes.

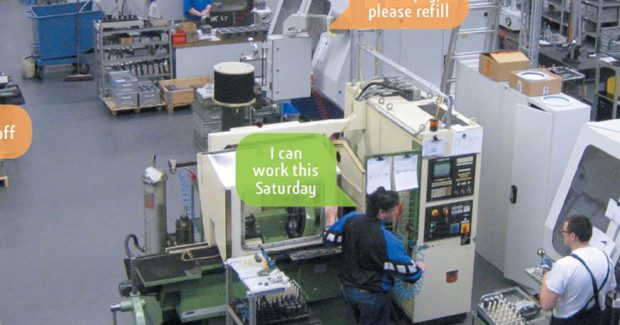

SHOP FLOOR CONTROL

Everybody needs to manage their production activities so resources stay focused and jobs are delivered on time. As work orders are created, individual routing sequences are established and scheduled and component material requirements are identified as dependent demand on the work order. Also, over-scheduling is avoided because you have clear visibility of resource allocation, like tools and processes.

Jobs are tracked in a real-time basis and production capacity is optimized. Have somebody in the field that day? They can see what the rest of your team sees on their mobile device, because the software is web-based and not dependent on the location of a desktop workstation.

COST CONTROL

Tracking job costs is critical to providing accurate and timely quotes, and you may have already discovered some of the shortfalls of using spreadsheets to do this. Get the ability to automatically collect actual costs on the work order, such as material, labor, and burden and outside process costs, make real-time inquiries into estimate vs. actual costs, and aggregate job cost data to easily adjust costing standards. This becomes a simple dashboard report that reveals both opportunities for improvements and confidence in decision-making.

BOOST MARKETING AND SALES

Customer relationship management (CRM) systems can be used to support important business development tasks, such as managing your prospects, qualifying and following-up on sales leads, coordinating each step in the sales process, and collecting valuable data on what is working and not working in marketing and sales.

The truth is that most manufacturers do not need the overly complex functionality of a stand-alone CRM system. Only a configurable solution allows you to use only what you need yet still reap the benefit of this important customer management tool.

SUPPLY CHAIN MANAGEMENT

Managing inventory levels and material costs are important aspects of creating profitability. What if you could tie inventory and purchasing together to reduce customer lead times and manage inventory in real-time? Inventory is managed automatically and inventory balances are optimized.

Likewise, purchasing is streamlined from purchase order generation through vendor management and price history management. Material requirements planning (MRP) is an important component in supply chain management, allowing you to accurately schedule orders, optimize material resources and improve cash flow with faster deliveries.

SEAMLESS INTEGRATION WITH ACCOUNTING

The ability to integrate your current accounting system with a manufacturing software solution will streamline your business. All business transactions (invoices, receipts, inventory changes, and much more) flow directly into your current accounting system, which includes accounts payable, accounts receivable, general ledger (GL), budgeting, financial reporting and payroll. Your company benefits from the elimination of dual data entry, reduced time to close financial periods and greater visibility into financial status.

LASTLY, A FEW TIPS

This all sounds pretty good so far, right? But before you jump into the arms of the next vendor promising Cloud delivery, here are a few important things to keep in mind:

Business processes should always drive the software, not vice versa. While many metal fabrication processes are similar, no two job shops handle them the exact same way. If your Cloud provider can’t work within your established best practices and wants you to change your business processes to accommodate the software, keep looking.

Make sure you carefully outline the project scope and requirements up front. This will save you a good deal of time, money and frustration downstream. Your software vendor should make this process very simple for you by guiding you through a needs assessment and solutions plan.

Ask for specifics related to configurability. Most Cloud providers are very limited in their customization or configuration capability. You may need to do more than rearrange report fields or add data. Adapting the solution to your unique manufacturing process may only represent 30 percent of your requirement, but it is the key to your long-term success with the software and critical to your competitive advantage. If the Cloud software provider cannot build a fit for purpose system for you, keep looking.

Whenever possible, use a Cloud application developed for your specific industry and not a generic version. For example, most enterprise resource planning (ERP) systems have a general structure because they can be used by a wide variety of businesses. Such systems require a large investment in customization, training, and customization to meet the unique needs of fabricators.

One size does not fit all. The right partner can make a big difference in successful implementation. Look for a supplier that not only thoroughly understands the application you are considering, but also has good knowledge and extensive experience in the metalworking industry. You deserve a system that is easily configurable to your specific requirements!