Deep Internal Grooving of Oil & Gas Parts

The CoroCut QD system from Sandvik Coromant includes CoroTurn SL blades that keep vibration to a minimum for deep internal grooving and parting off with long overhangs.

Posted: January 27, 2015

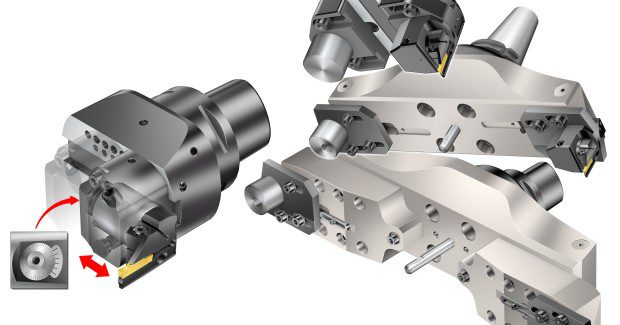

The CoroCut QD system from Sandvik Coromant US (Fair Lawn, NJ) now includes CoroTurn® SL blades for deep grooves in internal machining. The modularity of the CoroTurn SL interface enables tool assemblies optimized for the specific application.

Internal grooving and parting off with long overhangs requires stability and tooling solutions that keep vibration to a minimum. CoroCut QD tools offer a stable clamping mechanism so that Silent Tools™ dampened boring bars can be used for vibration-free machining with long overhangs. For tube-shaped components, typically found in the oil and gas industry, this is welcome news enabling deep internal grooving to be machined with high process security.

As with the previously introduced CoroCut QD tools, the extended assortment features over- and under coolant. The over coolant easily handles chip control while the under coolant prolongs tool life further securing the machining process.

Sandvik Coromant is a global leading supplier of cutting tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development we create unique innovations and set new productivity standards together with our customers.

These include the world’s major automotive, aerospace and energy industries. Sandvik Coromant has 8000 employees and is represented in 130 countries. We are part of the business area Sandvik Machining Solutions within the global industrial group Sandvik.

Sandvik Coromant US, 1702 Nevins Road, PO Box 428, Fair Lawn, NJ 07410, 800-726-3845, Fax: 201-794-5257, www.sandvik.coromant.com.