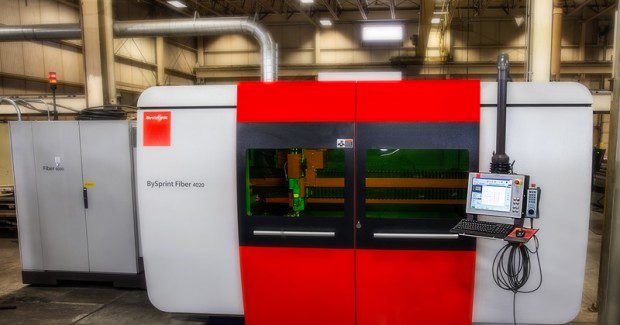

D&S Manufacturing Adds Fiber Optic Cutting System

This is one of the first U.S. installations of a new 6 kW fiber laser cutting system from Bystronic.

Posted: January 23, 2015

D&S Manufacturing (Black River Falls, WI) is proud to be one of the first manufacturing facilities in the U.S. to take advantage of the newest innovations in fiber optics by installing a BySprint Pro 4020 6 kW Fiber Laser cutting system from Bystronic, Inc. (Elgin, IL). With this new equipment, the company will continue to provide exceptional quality plate metal fabrications while reducing operating and maintenance expense.

In reviewing the CO2 unit to be replaced, management recognized that the greatest amount of down time came from required maintenance and inconsistency over time in CO2 laser cutting. According to John Gulso, the operations manager, “When considering the ongoing expense of down time and maintenance costs associated with CO2 lasers, it was determined early on that we would pursue fiber optics to give us the best opportunity to increase usable time and decrease maintenance and operating expense.”

D&S has researched fiber optic cutting equipment for the last 3-4 years and is excited to add this leading edge equipment to its lineup. Recent technological advances in fiber optic cutting have been adapted which allow for cutting plate metal up to ¾ in thick. By gathering feedback from customers and suppliers, the company has learned that Bystronic has become a vendor of choice for providing quality equipment and excellent customer support.

There are significant advantages of fiber optics over CO2 cutting. By delivering the beam to the cutting head through a fiber optic cable the use of mirrors to transmit the beam is eliminated. This creates a closed system which cannot be infiltrated by dust and dirt. There are no mirrors which can become misaligned or optically degraded with use requiring maintenance. With fiber optics, the system remains cooler eliminating the need for a chiller.

A cutting beam delivered through fiber optics continues to run at optimal performance, remaining constant over time providing a consistent cut quality. This BySprint unit utilizes a highly efficient resonator and also saves energy by automatically switching off when the door opens or the unit is on standby, further reducing operating expenses.

The 6,000 watt BySprint system is equipped with two 80 in by 160 in tables. While the fiber optic cutter requires a full enclosure, it also offers the potential to add load and unload automation to provide for lights out operation. As D&S continues to analyze cutting requirements it will be able to take advantage of this feature.

Since 1965, ISO 9001:2008 certified D&S Manufacturing has served as a custom manufacturer of exceptional quality large scale components, assemblies, and complete weldments. Our customers include Caterpillar, Oshkosh Corporation, Parkson, The Trane Company and CNH. Capabilities include: laser, high definition plasma, and oxy-fuel cutting; vertical and horizontal machining; and manual and robotic welding.

Additionally, we offer liquid spray painting, powder coating, shot blasting, assembly and testing. Our dedicated and highly skilled workforce live a commitment to superior project management, exceptional quality, accountability, teamwork, and continuous improvement, empowering our employee owned company to live its slogan, D&S Solid™.