High Performance Cutting of Aluminum

The Cool Injection-Plus system of PCD monoblock cutters and PCD cartridge cutters from Lach Diamond can achieve feed rates up to 40.000 mm/min.

Posted: January 27, 2015

High Performance Cutting (HPC) is indispensable for industrial machining in the automobile and aircraft industry, wind energy and their component suppliers. To meet this demand, the “Future for Today” is a determining factor and the guiding theme of the diamond and CBN tool manufacturer Lach Diamond Inc. (Grand Rapids, MI) in its first comprehensively introduced program, Cool Injection-Plus, which “shapes innovations of today for tomorrow‘s future.”

This program already fulfills today what the industry for HPC of aluminum and fiber composites expects, with drastic cost reductions through:

- Cycle time reduction of 50 percent and more

- Higher manufacturing output

- Stock removal rate up to 10 mm with maximum cutting speed

- Reduction of rework

- Set-up time and energy saving

PCD high performance cutters are proven cost killers in the automobile industry and are constantly adapted to the new, resulting requirements also for machine manufacturers. Significant patents attest this ongoing successful development. Cool Injection-Plus is an example of this.

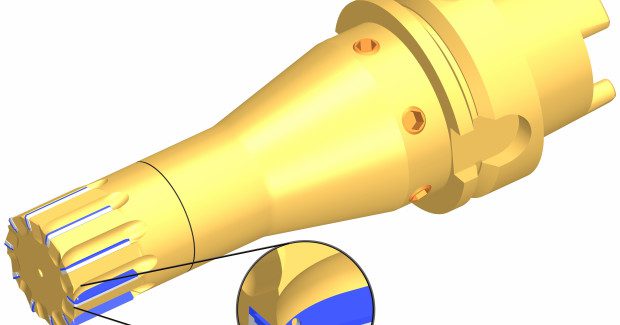

The Cool Injection-Plus program stands for innovative milling of primarily aluminum with PCD monoblock cutters and the PCD cartridge cutters from ø 16 to 400 mm. Based on special manufacturing technologies, the users of PCD cutters have the maximum possible number of teeth available which allows feed rates up to 40.000 mm/min with maximum cutting speeds.

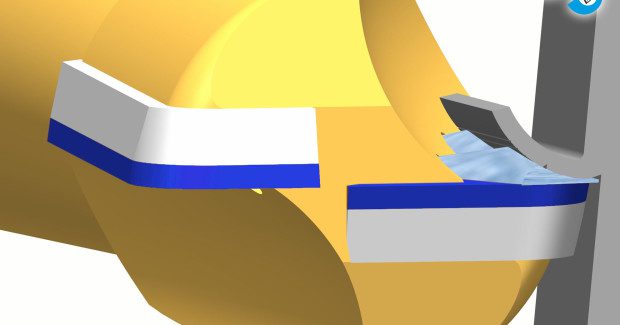

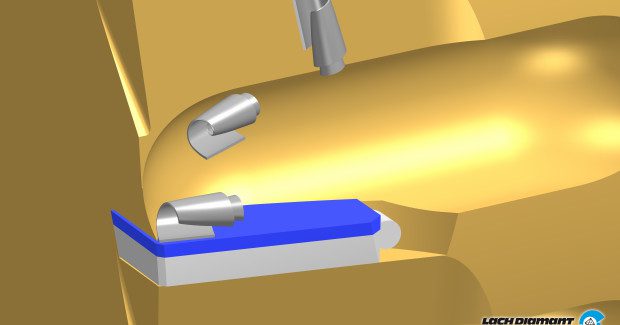

The patented Cool Injection system direct cooling whereby the cooling stream hits the PCD cutting edge directly on the just emerging chip and chip breaker Plus and thus completes the choice of maximum possible high performance cutting with Lach Diamond PCD milling cutters.

A comprehensive presentation of the ideal combination of Cool Injection-Plus for the innovative cutting of aluminum for practical advantage is ready for all users on the company’s website.

Lach Diamond Inc., 4350 Airwest Drive, SE, Grand Rapids, MI 49512, 616-698-0101, Fax: 616-698-0232, sales@lachdiamond.com, www.lach-diamond.com.