Never Too Dense

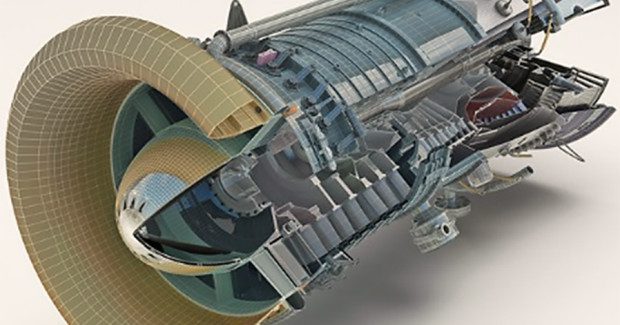

Advanced scanning technology can now perform 3D analysis of a scanned turbine blade, automatic pour porosity volume analysis on an aluminum casting, 3D measurements with nominal-actual CAD comparisons on a machined aluminum cylinder head – and more.

Posted: January 31, 2015

Exact Metrology (Cincinnati, OH) is a comprehensive metrology services provider that offers customers 3D scanning, reverse engineering, quality inspection, product development and 2D drawings. With ISO 9001:2008 certified facilities in Cincinnati and Milwaukee and affiliated offices throughout the Midwest, the company also provides turnkey metrology solutions that include equipment sales and lease/rental arrangements.

Exact recently acquired a new metrology grade GE Phoenix v|tome|x m, a CT scanner system with dual tube technology, nanofocus to 180 Kv and microfocus to 240 Kv, to significantly expanding their capability in 3D scanning to 2 microns with sufficient power to measure denser parts. They are the first company in the U.S. to purchase this system, according to company sources.

Company president Steve Young notes, “We bought this system because it has significantly greater accuracy, better detail and great reliability. We are currently seeking users for this new system.” The system has already received operational approval from the state of Ohio and is installed at the company’s main facility in Cincinnati.

The Phoenix v|tome|x m system features a unique temperature stabilized detector array (up to 30 fps) for extremely fast CT data acquisition on workpieces up to 500 mm diameter and 600 mm in height, weighing up to 50 kg (110 lb). Typical functions performed on this system might include 3D analysis of a scanned turbine blade, automatic pour porosity volume analysis on an aluminum casting, and 3D measurements with nominal-actual CAD comparisons on a machined aluminum cylinder head.

Exact offers this service for process control and customer R&D functionality, plus scientific research applications. With full CT automation, click and measure capability and the dual tube technology, this new system can perform analyses on an extremely wide range of samples, from high-resolution nano CT of low-absorbing samples to the high-power micro CT applications, such as engine turbine blades. Other applications for possible utilization of this new system include light metal castings, electronic assemblies, thermoplastic molded and composite parts, plus all types of machined metals.

Compared to conventional tactile or optical CMMs, this new scanner system can generate a first article inspection report including internal dimensions in less than one hour, with high accuracy and repeatability. Utilizing the GE Phoenix Datos|X CT and Volume Graphics software platform further enables full automation of the system, thereby reducing the time to perform the testing procedures.

Exact Metrology, Inc., 11575 Goldcoast Drive, Cincinnati, OH 45249, 513-831-6620, www.exactmetrology.com.