5-Axis Laser Cuts Costs at Kryton

This technical review examines how 5-axis laser processing dramatically improved the secondary processing of 3D parts at this high tech job shop.

Posted: February 2, 2015

Kryton Engineered Metals Inc. (Cedar, Falls, IA), a precision custom fabricator that specializes in the manufacture of concentric parts, has embraced the benefits of laser technology. Established in 1981, the company has steadily grown into a high tech contract manufacturer serving a wide range of industries, including industrial air handling, lighting, medical, communications, automotive suppliers, food and chemical equipment manufacturers, as well as niche markets.

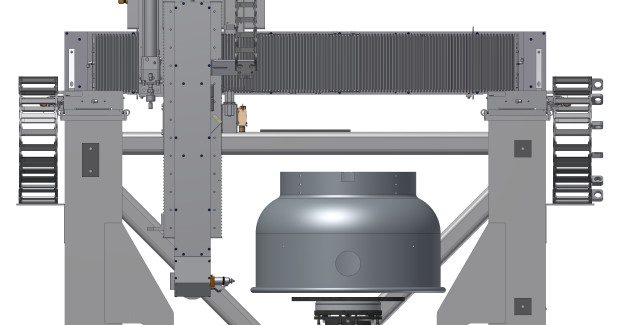

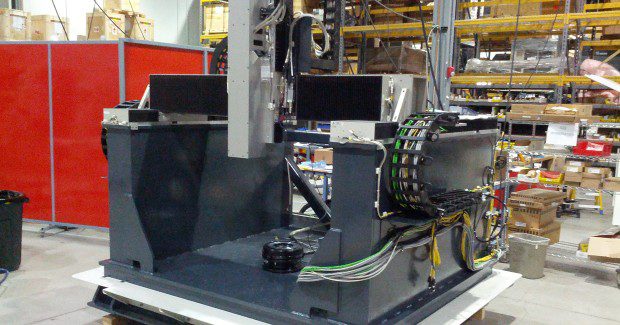

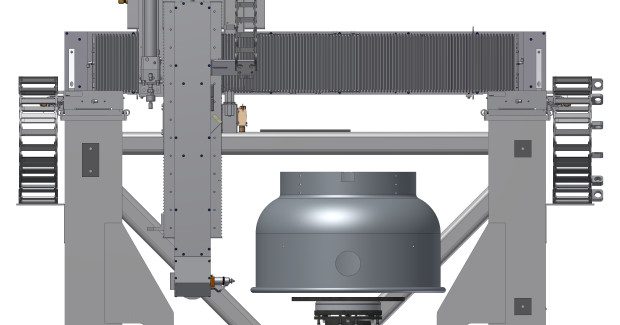

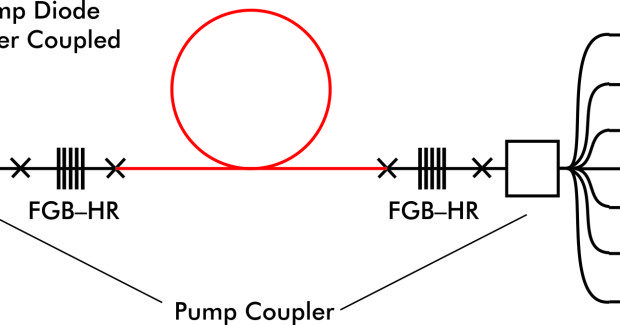

Management recognizes that employing advanced manufacturing technology increases productivity, reduces costs and improves quality while responding faster to customer needs. Their most recent acquisition is the UW505 2,000 Watt 5-Axis Fiber Laser Work Station from Rofin-Sinar, Inc. (Plymouth, MI) for the cutting of 3D parts.

Most parts here are produced in-house from either metal spinning, stamping or deep drawing, though the job shop also provides contract services for companies that require secondary processing of their 3D parts. For the past few years they have cut sheet and plate materials with a Cincinnati CL707 powered by a Rofin DC035 CO2 laser. When Rofin consulted with management to modify the UW505 5-Axis Fiber Laser Work Station, the company embraced the opportunity improve how they process their 3D parts.

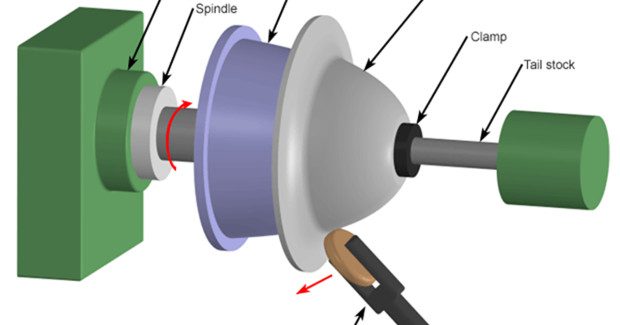

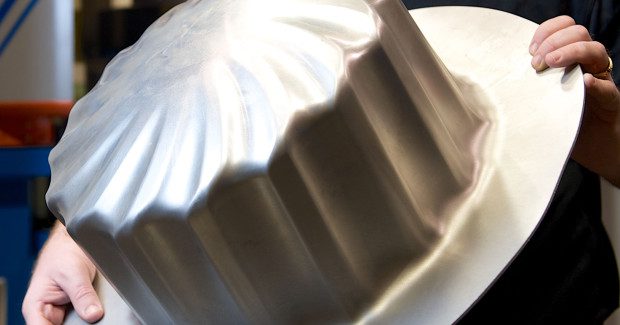

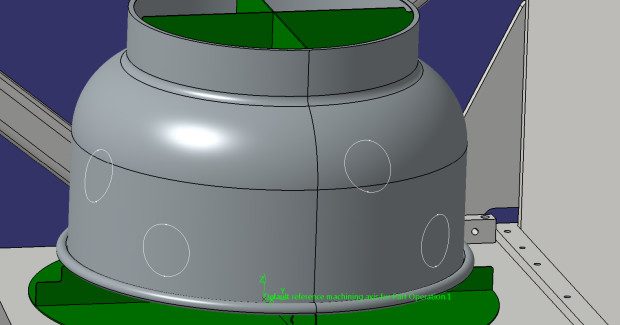

Metal spinning parts here represents a unique type of 3D fabrication because of the method employed to create the part and the challenge of cutting secondary features. Figure 2 depicts the metal spinning process that is performed on eight CNC machines.

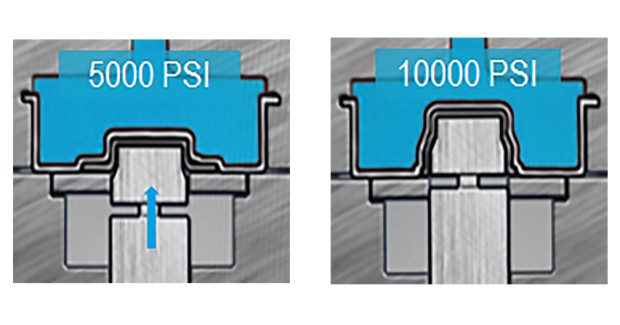

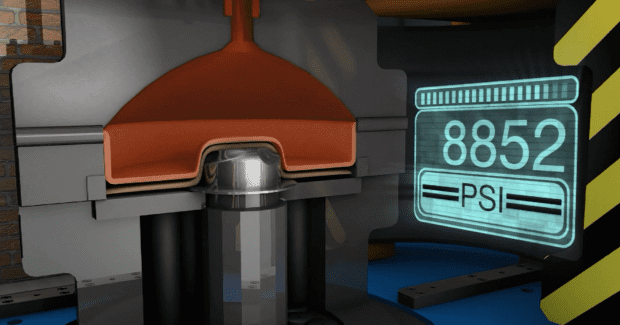

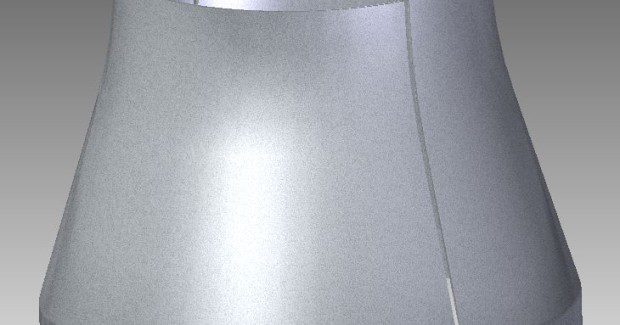

Deep draw and hydro-formed parts represent another challenging 3D fabrication for Kryton, as shown in Figure 3. Another challenge facing the shop is the wide range of materials being handled, including steel, stainless steel, aluminum, copper, brass and other specialty alloys. Raw material thickness ranges from .010 in up to .500 in and part diameters from 3 in to 120 in. Most parts mandate dimensional and hole accuracies of +.010 in or greater, but some jobs require over 50 percent tighter tolerances. Lot sizes are generally small to medium volumes that require fast setup and changeover capability.

Since each 3D part Kryton produces represents a hefty investment in material costs, labor and equipment burden rates, it is critical that secondary processing does not deform and scrap the part. Hole, slot and flange cutting requires accuracy and edge quality while maintaining the part shape integrity. Most parts are concentric because they are produced on CNC metal spinning lathes or formed in stamping dies or deep draw tooling. During the processing of the material, the original material thickness can be reduced dramatically as the metal is stretched and formed.

The question the job shop always had to answer in processing these different 3D parts was: How do we efficiently and accurately position the part and perform a precision, high quality cut in a thin-walled metal alloy without deforming the edge or contour of the three-dimensional surface? The answer usually involved several complex steps:

- Making a fixture that conforms to the part geometry.

- Securing the part in a fixture that guarantees repeatable positioning.

- Accurately locating the position of holes, cutouts and flanges according to the 3D part print.

- Preparing and utilizing a machine tool, die, punch, drill, saw or hand tool to process the part.

- Processing the part without deforming the part.

- Deburring or rework to insure high quality edge condition and contour.

- Repeating the process in the future when customer orders more parts.

- Modifying processes 1-7 when design changes occur in the part.

Steps 1-7 represent labor and/or equipment components with costly burden rates. More importantly, each step adds handling to the overall manufacturing time of the part, limiting production throughput. Kryton addressed all of these processing challenges by developing part fixtures, custom die punches and drilling fixtures; utilizing CNC lathes and machining equipment; and manually using hand tools on hard-to-access material removal or deburring.

Frequently, complex parts required multiple setups and secondary processing such as drilling, die punching, flange trimming and de-burring. Figure 4 depicts examples of a custom drilling fixture and a punching die for the secondary processing of parts. Note that the design, construction and inventory of fixtures and dies also contributed to the manufacturing costs and burden rates. As an alternative to in-house secondary processing of 3D parts, the shop outsourced some of the work to a local custom fabricator – which added costs and increased lead times.

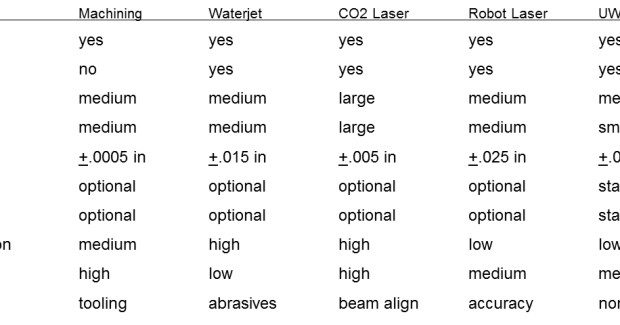

This led the company to investigate a variety of CNC systems to improve 3D part processing, as shown in Figure 5.

The UW505 is equipped with the Siemens 840 control that manages all aspects of the cutting parameters, including dynamic power control, feed rates and assist gas pressures, tool paths, axis motions and related functions. The machine and control are configured to recognize the surface and center of the rotary table as the absolute point (0, 0, 0) of the work zone. This design feature facilitates the simple referencing of the part and fixture in the work zone. The absolute point also aids in the design of the part fixture as well as the CAD/CAM programming of the tool path.

Because the small-to-medium lot quantities of Kryton applications require fast setup and changeover, CENIT FASTRIM software was selected to provide the post processor and CADCAM programing for the UW505. Using CATIA software as a 3D CAD platform, CENIT can import 3D part models and quickly generate part fixture design, machine simulations and CAD/CAM programs for part processing.

Kryton has entered and processed over (90) different part numbers with the UW505 and CENIT software. Figure 13 shows three examples that were selected to represent a cross-section of typical applications on different shapes, materials and operations.

Part One is a metal spinning part which appears to be a simple .109 in steel can with a 10 in diameter transitioning to 6 in. However, the part requires the cutting of two slots, top and bottom flanges and a perpendicular longitudinal cut to create two identical halves. Accuracies are not critical with +.015 in, but symmetry of features is crucial. The production required multiple part handlings and machine setups. Processing 100 of these parts is summarized in Figure 14 to demonstrate the challenge of performing secondary cutting operations. Each part required five handlings, three machine setups, and the costly replacement of ten new $29.00 saw blades at 0.25 hours per blade setup.

In comparison, the UW505 processed the same 100 parts in one part handling and machine setup while eliminating de-burring and costly consumables, saving nearly 23 hours of labor and machinery burden rate – over $13.00 per part:

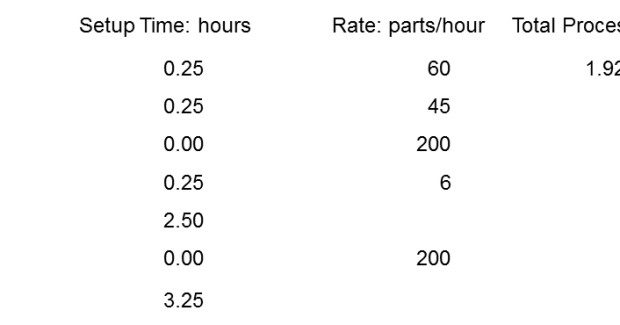

Description Setup Time: hours Rate: parts/hour Total Process Time

UW505 laser cutting 0.25 60 1.92 hours

TOTALS 0.25 1.92 hours

Part Two is a .120 in stainless steel tank made from metal spinning, with 19 holes located on the top flange and side walls. Hole diameters range from 1.5 in to 0.375 in with an accuracy specification of +.005 in. The hole locations require dimensional and angular placement precision. The tank diameter is 20.50 in and height is 24.75 in. To insure part accuracies and eliminate the risk of part deformation during the secondary processing, Kryton outsourced this part to a laser job shop.

Figure 15 details the processing steps, time and expense for outsourcing 100 of these parts to a laser job shop. The job shop’s CAD/CAM software and multi-axis laser capability were not disclosed, but the extra handling, preparations and production required approximately 11.50 hours for 100 parts.In comparison, the UW505 processed Part Two in two simple setups: cut 16 holes in the tank walls and then cut three holes in the top flange. The total laser cutting time for 100 pieces was 4.88 hours, approximately 42 percent less time than outsourcing – saving over $20.00 per part. The turnaround time to the customer was also reduced from over three weeks to less than one week. By eliminating costly packing and shipping of parts, paying for outsourcing and long lead times, Kryton saved time and money:

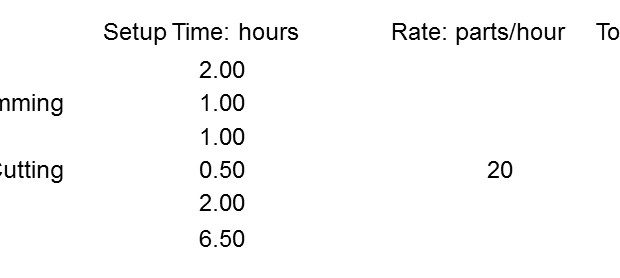

Description Setup Time: hours Rate: parts/hour Total Process Time

UW505 laser cutting 1 0.25 30 3.58 hours

UW505 laser cutting 2 75 1.30 hours

TOTALS 0.25 4.88 hours

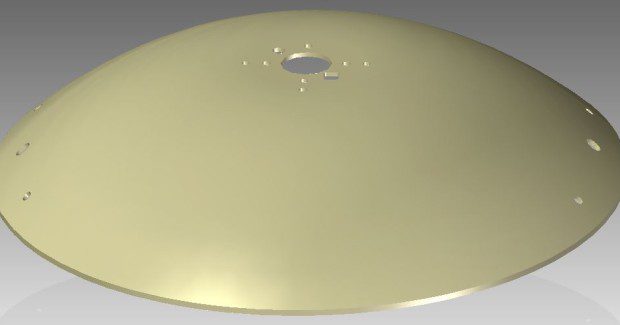

Part Three is manufactured by either metal spinning or a press operation. This .090 in aluminum dish has 16 precision holes ranging from 1.010 in to .166 in diameter. All of the hole diameters require tolerances of +.005 in and accurate dimensional placement on the disk of +.015 in. Because of these requirements and the critical part contour of the dish part, Kryton created a drilling fixture to locate and drill the holes. A .300 in x .300 in slot also required a custom die and punching operation. Outsourcing Part Three represented another alternative.

Figure 16 shows the in-house processing time for 100 pieces of Part Three, outlining the three separate material handlings and two setups needed for a low processing rate. Outsourcing to a laser job shop was quoted at more than $7.00 per part, not including the time and expense of packing and shipping.The UW505 dramatically reduced the production time for processing 100 of these parts, achieving the required accuracy and quality while saving approximately $5.00 per part versus in-house drilling and punching. This represents thousands of dollars per month since Part Three runs in large volumes.

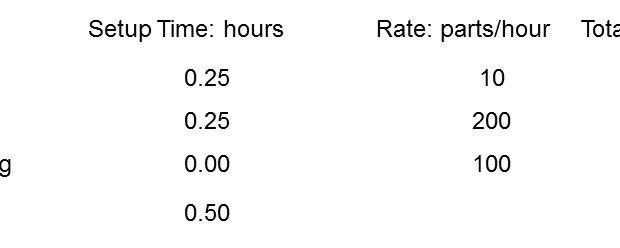

Description Setup Time: hours Rate: parts/hour Total Process Time

UW505 laser cutting 0.25 100 1.00 hours

TOTALS 0.25 1.62 hours

After completing one year of operation, including the learning curve, Kryton summarized the benefits of the UW505 Fiber Laser Work Station:

- Processing flexibility has been realized.

- Multiple processing steps have been reduced to one laser cutting step.

- Efficient fixture generation has reduced tooling production costs and expenses.

- Elimination of rework has been realized for many jobs.

- Better part accuracy and repeatability has been achieved on all parts.

- Operator safety has been enhanced by reducing part handling and hazards.

- Outsourcing has been dramatically reduced for challenging parts.

With the ROI and project payback estimated to be approximately 1.5 years before tax incentives and depreciation considerations, this investment in 5-axis laser processing with the UW505 has dramatically improved the secondary processing of these 3D parts.