HOUSTEX 2015

Hundreds of exhibitors will highlight the latest manufacturing technologies for parts suppliers to the oil and gas industry and other related market sectors at this year’s event in the George R. Brown Convention Center in Houston on February 24-26, 2015. Here is a review of some of the machinery and tooling that will be on display.

Posted: February 23, 2015

BROACHING TOOLS REDUCE CYCLE TIME, INCREASE MACHINE LIFE

In Booth 454, BENZ Inc. (Charlotte, NC) will demonstrate several new LinTec broaching tools, including the LinA Axial and Radial Broach, the LinA XL Radial Broach, the LinS Axial Broach, the LinA Haas Axial, and the LinA EMAG Axial.

The LinA broaching system changes the rotary motion of the live tool turret into a linear motion for broach and spline machining on turning centers. With the LinA in place, the programmer can position the Z-axis to the start position and program a constant X feed until the broach depth has been achieved, at 1000 rpm/1000 strokes per minute. It utilizes an integrated feature that lifts the tool .006 in off the material on the return stroke for a better surface finish and tool life. A typical 3/8 in x .187 in x 1.250 in keyway would take almost two minutes to cut on a lathe. The LinA can machine the same feature in steel in 6 to 8 seconds. BENZ offers the LinA radial and axial models, available in short, standard, long and XL stroke versions.

The LinA Broach for BMT and VDI applications is available in six different models engineered for specific applications. The LinA Radial FSS has a short .669 in stroke, higher operating speed, greater stability, improved surface quality and can broach a .375 in x .187 in x .699 in keyway in 5 to 7 seconds. The LinA FS Radial has a 1.259 in stroke and can broach a .375 in x .187 in x 1.259 in keyway in 6 to 8 seconds. The LinA FSL Radial has a 2.007 in stroke and can broach a .375 in x .187 in x 2.007 in keyway in 7 to 9 seconds. The LinA XL is designed for large turning applications and large diameter parts, with a larger 3.937 in working stroke and groove width up to .7874 in. Driven by an auxiliary motor, the LinA XL is a special broach designed for non-live tool lathe applications.

The BENZ LinA Axial Broach is available in two different models and three different lengths. The LinA FSS, FS & FSL models for Haas Axial lathe applications have strokes of .669 in, 1.259 in and 2.007 in. The LinA Axial EMAG is designed specifically for the EMAG VL 3 lathe application.

The BENZ LinS broaching tool system is a one-of-a-kind system that enables programmers to broach splines, torx, hex and keyways on their machining centers. The LinS provides broaching solutions without compromising either spindle or spindle-bearing integrity. By rotating the spindle at 50 rpm, the LinS provides spindle and bearing protection and the torque arm eliminates oscillating spindle conditions which will cause the broach insert to chip. The LinS can also be adjusted manually to provide 360 deg rotation and can be used with a fourth axis to create splines, torx and hex shapes.

BENZ, Incorporated, 8325 Arrowridge Boulevard, Charlotte, NC 28273, 704-529-5300, Fax: 704-529-5009, www.BENZ-inc.com.

MODULAR ADAPTORS AND BASES SHORTEN CHANGEOVER TIMES

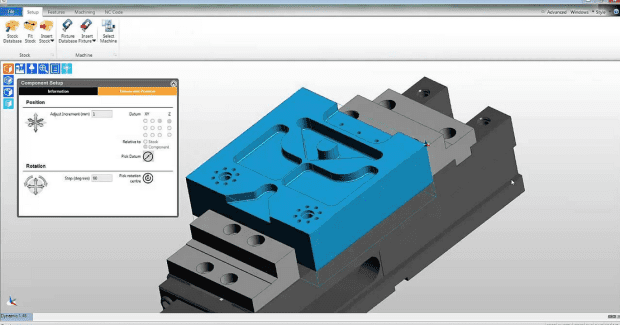

In Booth 1341, Exsys Tool, Inc. (San Antonio, FL) will showcase its well-known, high-quality and innovative Exsys/Eppinger tooling systems, where visitors will discover the speed, flexibility and cost-effectiveness of such systems as Preci-Flex®, Deco-Flex® and Compacto.

The Preci-Flex modular system provides fast, accurate lathe tooling changeovers. It is the first tooling system on the market with a single base holder and multiple tooling adapters that utilizes the ER collet pocket. The system’s compact design ensures maximum torque transmission and rigidity, resulting in increased machining accuracy, improved productivity and longer tool life of perishable tools. Additionally, Preci-Flex’s conical and flat face planar interface allows the use of either an adapter or a standard ER collet, and enables collets, endmill holders, expanding collet chucks and shrink-fit tooling to be mounted on a single-base holder. Preci-Flex is effective in small, medium or large production runs.

Designed specifically for small part manufacturing applications, the high-accuracy Deco-Flex tooling interface offers unmatched flexibility, precision and cost savings. It is ideal for use on turning and milling centers with limited working areas. Deco-Flex was designed with minimal envelope dimensions that allow job shops to realize a variety of new manufacturing approaches previously impossible with other tooling systems on the market. The compact design ensures maximum torque transmission and rigidity, resulting in high machining accuracy, productivity and increased machine tool efficiency.

Deco-Flex features a conical and flat face planar interface that guarantees the best possible concentricity and repeatability for precise machining, as well as specific adapters that combine with fixed and/or rotary tool holders to optimize tool performance and increase flexibility. Manufacturers also benefit from reduced setup times and increased machining uptime, as Deco-Flex allows simple adapter/tool changes to be completed in seconds and can also pre-set tools off the machine.

The Compacto C3, C4 and C5 Connection Base Holder system enhances efficiency and productivity. And when compared with traditional designs, the compact size of the base holder provides more space for machining in tight workspaces as well as offers improved torque transmission and rigidity for increased tool accuracy. The Polygon Shape Connection (PSC) further adds to the system’s high precision and stability. A special built-in release mechanism on the outer diameter of the connection base holder’s spindle provides optimum operator accessibility. Operators can easily lock and unlock adapters with a small Allen key for fast and virtually effortless tool changes. Plus, the automatic ejection feature of the adapters further increases the speed and efficiency of tool exchanges.

Available for bolt-on and VDI-style turrets, the Compacto connection base holder accommodates fixed and rotary tools, including the Preci-Flex system, and accepts all standard PSC adapters. In fact, adapters used in milling applications will now work in turning operations, due to the versatility of the Compacto.

EXSYS Tool, Inc., 11654 Corporate Lake Boulevard, San Antonio, FL 33576, 352-588-4345, www.exsys-tool.com.

INNOVATIVE TOOLHOLDING FOR HIGH MACHINING PRODUCTIVITY

Rego-Fix Tool Corporation (Indianapolis, IN) will join its distributor partner, Robert H. Severance Group, Inc. (Grand Prairie, TX), who is occupying several booths throughout the show, to showcase its newest innovations in toolholding. On display will be a new version of the secuRgrip® anti-pullout toolholding system that can be used in any ER collet system and the Hi-Q®/ERMX Mini-Nut for Swiss automatic machine tool applications.

The secuRgrip system’s patented design provides a solid connection for high productivity machining operations. After the insert is placed into a tool’s standard Weldon endmill flat, screwing the tool into a collet that has a matching internal diameter profile securely locks the two together. The secuRgrip system works with standard carbide or HSS endmills 0.5 in to 0.75 in diameter, and provides TIR of 0.0004 in or better. A backscrew enables presetting of tool length, and the hardened steel locking inserts are size-specific per diameter.

The Hi-Q/ERMX Mini-Nut is for fast, secure ER collet nut clamping in Swiss automatic machine tool applications. Featuring an anti-slip locking design, these mini-nuts prevent the locking wrench from slipping off the nut during tool changes. As a result, machinists are able to protect their hands from injury when handling sharp cutting tools. Milled slots on the outside diameter of the nut mate with corresponding features of the wrench to prevent slippage during the tightening and loosening processes. The Hi-Q design includes a special surface treatment to enhance clamping forces. The Mini-Nuts replace any brand of older-style mini-nuts and are presently available in ER 16 and ER 20 sizes in standard and coolant versions.

Rego-Fix Tool Corporation, 7752 Moller Road, Indianapolis, IN 46268, 317-870-5959, Fax: 317-870-5955, www.rego-fix.com.

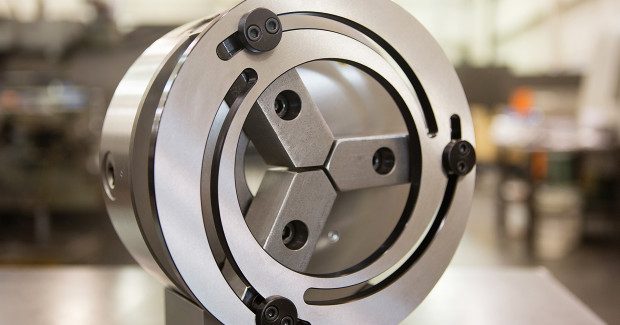

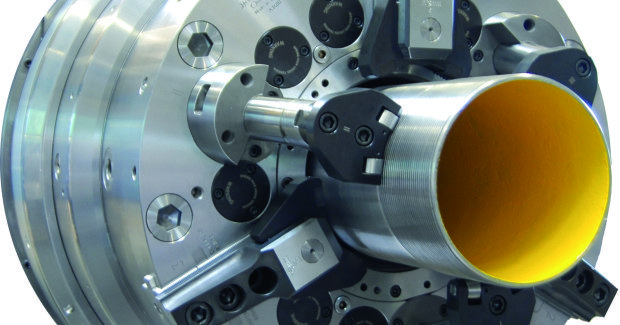

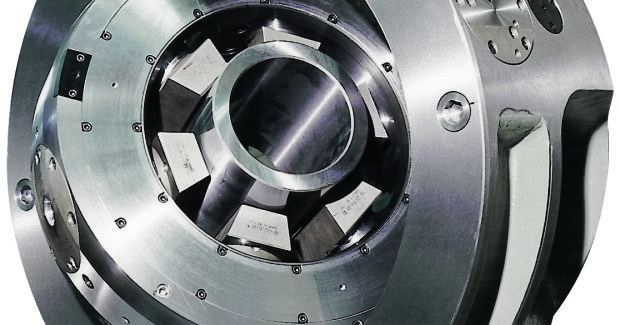

MAXIMIZE JAW LIFE ON CUTTING AND FORMING OPERATIONS

In Booth 2127, the jaw forming ring from Dillon Manufacturing, Inc. (Springfield, OH) is an easy-to-use tool that provides a more uniform grip on the workpiece thereby maximizing jaw life for cutting and forming operations. Mounted in direct contact with the top jaw, the jaw forming ring preloads the chucking system. Jaw life for requalifying or reforming is maximized by lessening the amount of jaw stock removal required during parts set-up.

Use of the device will provide a jaw surface true to the machine centerline, reduce set-up times, and increase up-times for running machined parts. Dillon jaws support a wide variety of industries including aerospace, agriculture, automotive, consumers, coal, oil and gas, construction, machine tools, mining, paper, rail and wind energy. Jaw forming rings are available for 5 in, 6 in, 8 in, 10 in and 12 in power chucks. They are capable of a wide range of OD and ID jaw formation. Self-centering action provides equal pressure on all jaws. The jaw forming ring is the only tool of its kind to compensate for “jaw lift,” even in worn chucks, which results in better parts concentricity.

Dillon Manufacturing, Inc., 2115 Progress Drive, Springfield, OH 45505, 800-428-1133, www.dillonmfg.com.