Improving Profitability with User-Friendly EDM

The complicated nature of the work and the current labor issues facing the industry mean that more user-friendly EDM is critical for your shop operation.

Posted: February 2, 2015

Manufacturers today strive to process more work faster, and attempt to do so despite the challenges of attracting qualified EDM operators. The shortage of skilled labor brings varying experience levels on the shop floor. Ensuring that quality and productivity are maintained no matter who is running the machine is a business requirement.

Historically, training a new operator to be fully proficient on a machine required specialized on- or off-site instruction. For that operator to truly learn the art of EDM work, including the myriad of settings, adjustments and machine maintenance procedures, it took countless hours of on-the-job, hands-on learning to perfect his or her craft. Knowing the complicated nature of EDM work and the current labor issues facing the industry, many shops want to know how to make EDM more user-friendly for the operation.

INTUITIVE INTERFACE

It all starts with the machine. Unlike the standardized FANUC control interface commonly used in milling machines, EDM interfaces are typically proprietary and can require retraining for even the most experienced operator. Without industry standardization, it is easier to look for features that operators are already familiar with using.

The intuitive touch-screen tap/drag/pinch interface found on all modern smartphones and tablets is one such example. Leveraging this design makes it possible to create something that anyone immediately feels comfortable using and exploring. By removing the typical learning curve for interacting with a new interface, an operator with no prior knowledge about a particular machine, or even EDM in general, can quickly be brought up to speed.

Similarly, an intuitive machine control interface that includes extensive on-board training and support makes operator transition to any new machine a non-issue, by avoiding the interruption to productivity that often accompanies off-site training. With text, audio and video training available on the machine tool, the answer to any potential question is literally at the operator’s fingertips. A new operator may immediately progress from learning how to do things on the machine to learning how to do things with the machine.

Of course, nothing replaces specialized training to achieve maximum efficiency and throughput, but having on-board tutorials provides an excellent educational resource to help maintain productivity levels.

BUILT-IN EXPERTISE

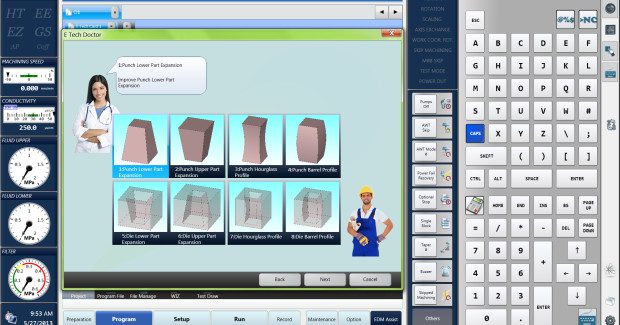

Like most machining, EDM is as much of an art as it is a science. Observing an operator who truly understands the numerous adjustments and settings on a given machine is like seeing a master sculptor create something not possible without specific expertise. When lesser skilled operators run into problems, they often rely on their more experienced colleagues, or they contact the machine’s manufacturer to discuss ways of achieving the desired performance results. This is time consuming and can drastically affect throughput until the issue has been resolved.

The creation of an intelligent “app” on a machine can transform a basic operator into an expert through automatic manipulation of the machine parameters based on the particular results that are being seen. The machine can analyze the issue and automatically modify cutting conditions to compensate without the need for consulting in-house engineers or contacting the machine tool OEM’s technical support. This intelligent software approach empowers operators to resolve these production issues quickly and easily in real time, thus increasing overall efficiency and productivity.

EFFICIENT MAINTENANCE AND ERGONOMICS

Machine maintenance can also benefit from the integration of advanced interfaces built on PC platforms. Not only can these newer EDM machines supply information on how to perform regular maintenance tasks with text, photos, audio and video, but it is also possible to intelligently track all machining hours and maintenance performed. Alerts pop up when maintenance is needed, along with direct instructions and video on how to perform the work.

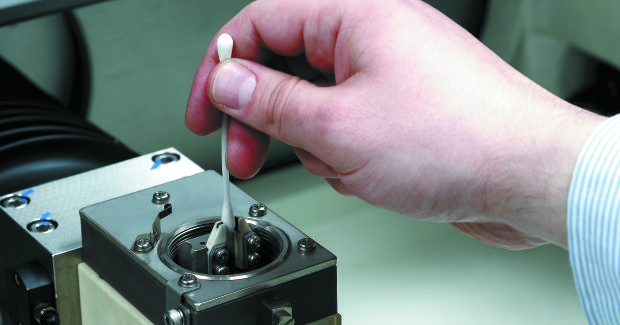

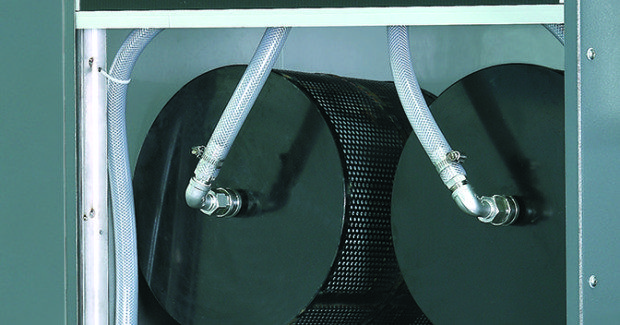

Also facilitating EDM maintenance is equipment that is ergonomically designed to easily accommodate physical access to the machine. Such a design helps reduce operator fatigue and errors, and it can also accelerate part changes and eliminate potential interference problems, bringing efficiency to part production. Some features of EDM machines are noted below:

- Fully retracting doors provide unrestricted access to the work zone and workpiece, including the bottom side of the workpiece and the machine’s lower head.

- Large doors swing out for open access to machine maintenance items.

- Wheeled wire collection bins offer easy movement and quick disposal.

- Tool-less component design reduces the time and tools needed to perform machine upkeep, such as energizer plate indexing.

- Advanced hand control boxes (pendent) with digital displays and access to all functions help to set up a machine without having to go back and forth to the main control panel.

- Large displays with touch screens make it easier to access information.

- The ability to customize and streamline the machine control is based on preferences, shift changes or operator skill level.

DATA REPORTING

The features mentioned above may make EDM machining easier, but almost every mold maker knows that key metrics must be tracked in order to fully analyze and understand the operation. These metrics help identify additional efficiencies for throughput and profitability as well as deficiencies and bottlenecks that should be corrected.

Often, in the push to get more out the door faster, many companies don’t properly track these metrics due to the level of manual involvement required to record, compile, analyze and report this data. Today’s intelligent machines can automate the entire process of tracking use, consumables, maintenance and literally every other operational parameter on the machine in order to provide insightful and actionable reporting.

A shop manager can analyze operational efficiency and know exactly how much machine time is being used by tracking these details:

- Machine filters

- Deionizing resin

- Wire consumption

- Water reservoir level

- Detailed cycle time information

- Actual cycle time vs. estimated/quoted time

- Machine utilization time (machining time / setup time / idle time)

This data makes it possible to know where improvements should be made and can be the difference between a shop having a good year or a great year.

EASE OF USE IS KEY TO PROFITABILITY

It’s very easy to get caught up in the speeds and feeds when evaluating today’s EDM machines, but if shops can’t make the machine perform to its limit, they are missing opportunities. Truly maximizing throughput and profitability requires getting the most performance from equipment and personnel. Ease of use might just be the feature that changes an EDM cell from one that just gets the job done to one that is a true profit center.