Put On Hold

The increase in higher precision machining is creating demand for stronger, more durable, faster acting, closer tolerance chucks and collets that can grip and hold the parts and the tools being used. Here is a review of some of the latest chuck and collet solutions that meet that demand.

Posted: February 27, 2015

CHUCKS

POWERFUL MACHINING FOR THE OIL INDUSTRY

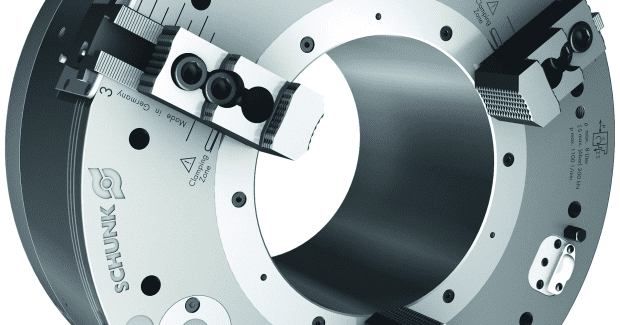

The ROTA TB2 pneumatic self-contained power chuck from SCHUNK, Inc. (Morrisville, NC) has set a new standard in the machining of rods and pipes for the oil industry, as well as in the mining and construction industries. This innovative power chuck has many features that help to fully utilize the productivity potentials of modern machining centers. It has a large through-hole up to 560 mm, with an air pressure of 6 bar, making it possible to achieve clamping forces up to 280 kN, which can easily be adapted to any particular task. An anti-corrosive coating significantly increases the service life of the chuck and the base jaw guidance is equipped with a special seal to prevent penetration of contamination, dust and chips, reducing maintenance costs. An advanced lubrication system ensures constant clamping forces and high process stability and an optional integrated pressure sensor provides maximum process reliability and operational safety in daily use.

http://youtu.be/MUZuY_4DNpg

To increase the cycle time in the machining of pipes and rods, the ROTA TB2 features a double acting check valve with extra large channel bores that considerably speeds up the clamping process. After completion of machining, a quick action ventilation system allows for a quick release of the clamping set-up. If needed, the extended jaw stroke can be mechanically monitored by a radial stroke indicator on the outer diameter. The TB2 is available in sizes from 470 mm to 1,000 mm with bore diameters from 185 mm to 560 mm. This chuck is interchangeable with all chucks and can fit on your machine today! The TB2 features faster actuation with its innovative exhaust system that allows for the quickest venting, ensuring decreased cycle times. The life of the TB2 chuck is dramatically longer due to an exclusive coating that assures resistance to wear and virtually eliminates corrosion.

In addition, the sealed base jaws eliminate contamination also increasing the life. To reduce maintenance, an advanced lubrication system allows for rapid and even lubrication of the entire chuck through an intelligent lubrication channel system. As an important safety feature, the TB2 has several pressure and stroke monitoring features that allow monitoring via an external monitoring system as well as monitoring via a dynamic wireless system offering constant up-to-date feedback. Additionally, the TB2 has an integrated sound absorber system to reduce noise and hearing protection.

For precise serial production, the SCHUNK ROTA NCO lathe chuck has the highest clamping force, the lowest jaw stroke, and the lowest height of any chuck in its class, ensuring more space in the engine room, shorter cycle times, and higher versatility. For economical productivity, the NCO offers several advantages, including a high clamping force and large jaw stroke that guarantees secure clamping across interfering contours and ensures maximum versatility. In ID and OD clamping, long base jaw guides support the chuck jaws so that high clamping forces are permanently maintained.

The relatively low weight of the lathe chuck reduces the mass that is moved during processing, allowing faster acceleration and deceleration in comparison to other chucks, which saves energy, shortens cycle times, and increases productivity. The jaw interface is optionally available with a fine serration of 1/16 in x 90 deg or 3/32 in x 90 deg or with a metric tongue and groove. Adjustable bronze wiper strips seal the base jaws against water and dirt.

SCHUNK, Inc., 211 Kitty Hawk Drive, Morrisville, NC 27560, 919-572-2818, Fax: 919-572-2818, info@us.schunk.com, www.us.schunk.com.

AUTOMATE PART LOADING WITH CHUCKS

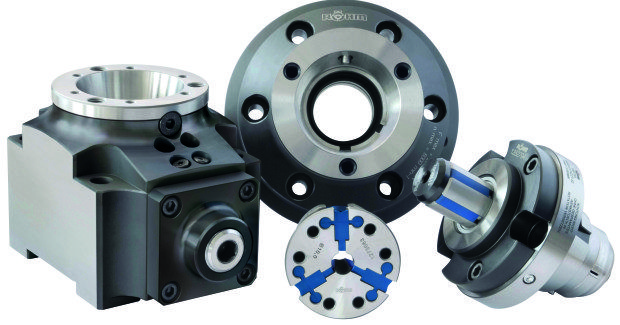

The worlds of workholding and automation collide with the addition of Unilock’s ESA 120/70 automation chuck from BIG Kaiser Precision Tooling Inc. (Hoffman Estates, IL). Unilock is known for reducing setup and changeover costs, but until now the standard knob program was limited when it came to automation. The new automation chuck series changes that by allowing for an intelligent interface and communication back to the controller using the standard Unilock knobs that thousands of customers already have implemented.

Table integration of the ESA 120/70 chucks allows robots to pick and place fixtured workpieces into the machine. The system checks for workpiece presence, proper orientation and clamping, and then communicates back to the controller when the workpiece is in place and ready to be machined. On the flipside, when a part is finished and removed from the work envelope, the machine knows nothing is loaded and will not allow a new cycle to start until a new component is properly in place.

Of course cleanliness of mating surfaces is of upmost concern during automated loading. The top surface of the ESA 120/70 has self-cleaning capability through an air blast originating off the chuck’s contact surface as the workpiece nears. Additionally, a slot was designed through the chuck that allows coolant or chips to flow out of the center clamping area and away from the precision locating features. For increased retention forces, the turbo assist feature boosts the clamping force to a max 1,870 lb, compared to the max 660 lb without it.

As typically seen with most chucks that utilize the standard Unilock knobs – the system has an impressive locating repeatability of .0002 in and a holding force of 11,240 lb. The Unilock system is a comprehensive positioning and clamping system that can be applied to almost any manufacturing or assembly process for a boost in productivity, bringing customers higher efficiency and agility. By automating the system, customers can achieve even higher levels of productivity without the need for constant human intervention.

BIG Kaiser Precision Tooling is a leader in high precision tooling systems and solutions, with brands including BIG Daishowa, KAISER, Speroni, Unilock, Sphinx and more that focus on extreme accuracy and repeatability. Guaranteed.

BIG Kaiser Precision Tooling Inc., 2600 Huntington Boulevard, Hoffman Estates, IL 60192, 847-228-7660, Fax: 847-228-0881, bigkaiser@bigkaiser.com, www.bigkaiser.com.

FULL BORE LATHE CHUCK FOR LARGER BAR STOCK

The Production Dynamics Full Bore collet chuck from Lexair Inc. (Lexington, KY) increases the through-hole capacity of lathe spindles by 25 percent to 30 percent by utilizing a self-contained mechanical-grip/air-release actuation system that allows use of a lathe’s full spindle bore capacity. The chuck’s unique design eliminates the drawtube needed for hydraulic chucks, creating the additional capacity. The U.S.-made Full Bore chuck ensures high machining accuracy, with concentricity adjustable from the front of the chuck. Its mechanical clamping action eliminates drawback on the stock, giving the chuck true fixed-length capability for faster, more accurate setup.

The quick-acting air-release chuck, with “open-on-the-fly” capability (under 500 rpm), helps minimize cycle time and machine wear. Available in eight sizes for stock diameters of 0.25 in to 5.5 in, the collet design is more compact than standard three-jaw chucks, offering improved tool clearance in the work zone, too. The Full Bore collet chuck is self-contained and requires no actuator, opening from the front in less than a second with shop air pressure, and clamping mechanically with internal die-spring pressure. The fail-safe system delivers constant grip force at all speeds, unaffected by centrifugal force like three-jaw chucks, ensuring safe operation at high rpm.

Clamp force is adjustable from the front, with visual force indicators on the front confirming the clamping status of the chuck and facilitating adjustment. Clamping force can be increased or decreased by adjusting the collet from the front with a simple spanner wrench. For softer stock, clamp force can be reduced further by removing springs inside the chuck. The Full Bore chuck uses standard S-style collet pads for economy. Lexair offers a range of accessories, including bar stops and parts ejectors, as well as precision-machined standard collets, master collets and pads, emergency collets, serrated collets, and custom-designed collets.

Lexair Inc., 2025 Mercer Road, Lexington, KY 40511-1018, 859-255-5001, sbreslin@lexairinc.com, www.lexairinc.com.

JAW FORMING RING PRELOADS CHUCK

The jaw forming ring from Dillon Manufacturing, Inc. (Springfield, OH) is an easy-to-use tool that provides a more uniform grip on the workpiece, thereby maximizing jaw life for cutting and forming operations. Mounted in direct contact with the top jaw, this jaw forming ring preloads the chucking system. Jaw life for requalifying or reforming is maximized by lessening the amount of jaw stock removal required during parts set-up. Use of the device will provide a jaw surface true to the machine centerline, reduce set-up times, and increase up-times for running machined parts. Dillon jaws support a wide variety of industries including aerospace, agriculture, automotive, consumers, coal, oil and gas, construction, machine tools, mining, paper, rail and wind energy.